NaN / 0

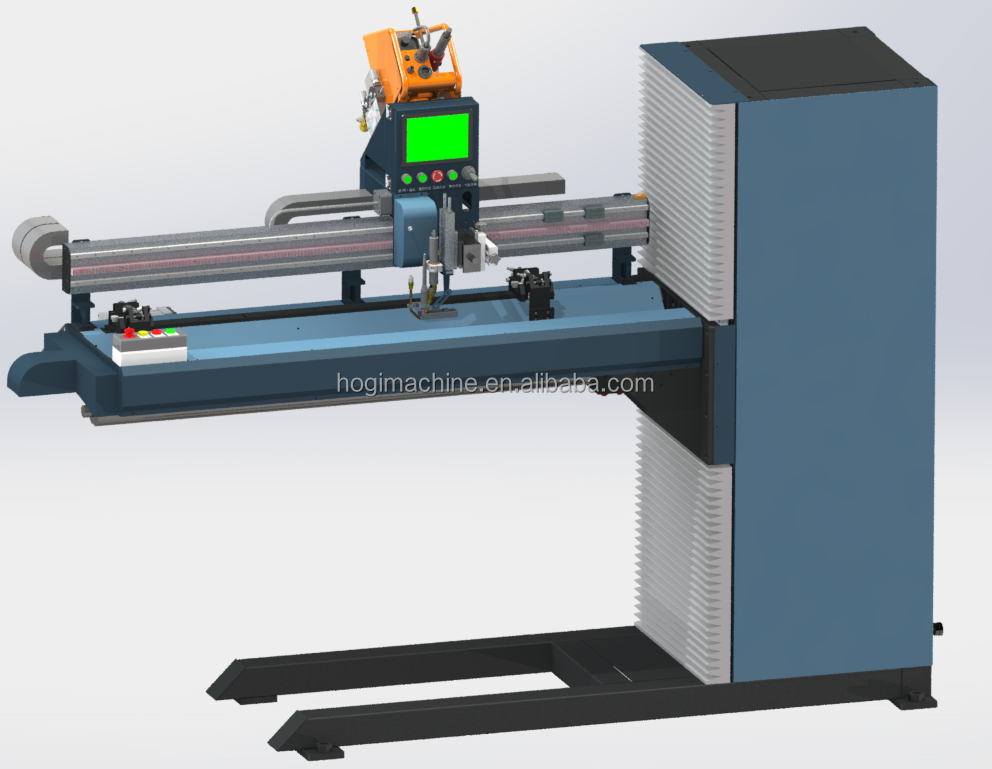

HOGI Automatic ARC Straight Longitudinal Seam Welder Tank Circular Stainless steel Welding Machine

Get Latest Price

US$ 15500

≥1 Sets

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

HOGI

Welding Mode:

tig mig laser

Welding Diameter:

150-1600mm, 150-1600mm

Product Details

Product Paramenters

|

Main parameters of HOGI Automatic straight seam welding machines

|

|

|

|

|

||||

|

Name

|

HG-600MM-3000MM

|

HG-700

|

HG-1000

|

HG-1500

|

||||

|

Welding forms

|

TIG tungsten arc welding, MIG/MAG shielded gas welding, PAW plasma welding, SAW submerged arc welding

|

3

|

6

|

6

|

||||

|

Thickness of welded workpiece

|

0.5-4MM

|

3-8

|

4-12

|

4-12

|

||||

|

Diameter of welded workpiece

|

150-1600MM

|

0.8-2.5

|

0.8-3.5

|

0.8-3.5

|

||||

|

Length of welded workpiece (customisable)

|

600-3000MM

|

100-300

|

150-450

|

200-450

|

||||

|

|

50-500

|

50-700

|

50-1000

|

50-1500

|

||||

Products Description

HOGI

straight seam welding machine(Optional Lifting type)

The lifting straight seam welding machine is mainly suitable for straight seam butt welding of carbon steel, stainless steel and other metal workpieces in medium and thin plate workpieces.

The straight seam welding machine can clamp and weld workpiece structures in the form of thin metal plates, cylindrical workpieces, conical cylinders, truncated cones, as well as box structures, flat plate splice joints, etc.

Main features:

1. This equipment has added a large cantilever and a cross beam that can be electrically lifted compared to the traditional platen type straight seam automatic welding machine.

2. The design principle of this machine is to use the piano key compression type mechanism to provide balanced workpiece clamping and cooling effect, and to export the excess heat on the workpiece from the weld seam quickly during welding to reduce the possibility of burn through of the weld seam as well as warping and deformation of the workpiece.

3. The machine can weld on one side and form on both sides. Many weldable metal materials can be welded on this automatic welding machine, such as stainless steel, carbon steel, weldable aluminium alloys and other metal materials.

4. Advanced control system, humanized human-machine operation interface, high degree of automation, stable and reliable performance.

5. Can be integrated with TIG tungsten arc welding, MIG/MAG gas shielded welding, PAW plasma welding, SAW submerged arc welding and other welding power sources and welding torches to form a set of automatic welding system.

Options: TIG automatic wire feeding system, welding machine, cooling water tank, etc.

Recommend Products

Hot Searches