NaN / 0

30 meters double suction sand dredger small sand barge jet dredging machine dragflow submersible slurry pump boat

Get Latest Price

US$ 45500

≥1 Sets

Quick Details

Application:

Industrial Utilities, Irrigation and Agriculture, Machining, Marine, Mining industry, Washing and Cleaning, Wastewater Transport and Flood Control, wastewater treatment, Water Treatment Solutions

Pressure:

High Pressure

Voltage:

380~440 V

Warranty:

365 days

Product Details

Heavy efficiency sand dredger small sand barge sand suction agitator boat sand suction jet dredger submersible slurry pump sand pump ZJQ

Sand Dredger Model: SD200-30-45

Components List:

1. Submersible sand pump ZJQ200-30-45

Discharge size: 6 ” (150 mm)

Flow Rate: 200 M3/hr

Head: 30 meters

Flow Parts Material: anti-wear high Cr alloy

Impeller type: close

Electrical Motor: 45KW-6P, 980 RPM

Max allowable solid size: 36 mm

Side-agitators: 5.5KW-4P; 43RPM

Total pump Weight: 2190 Kg

2. Sound-proof Gen-set

Brand: negotiable

Power: 100KW (137.5KVA)

6 cylinders; Turbo-charged; water cooling

3. Control Board

VFD start.

VFD brand: China brand or international brand

4. Winch

Main winch: 7.5 KW-8P; 380V; 50Hz

Side winch: 5.5KW-8P; 380V; 50Hz

Steel Rope: Customized

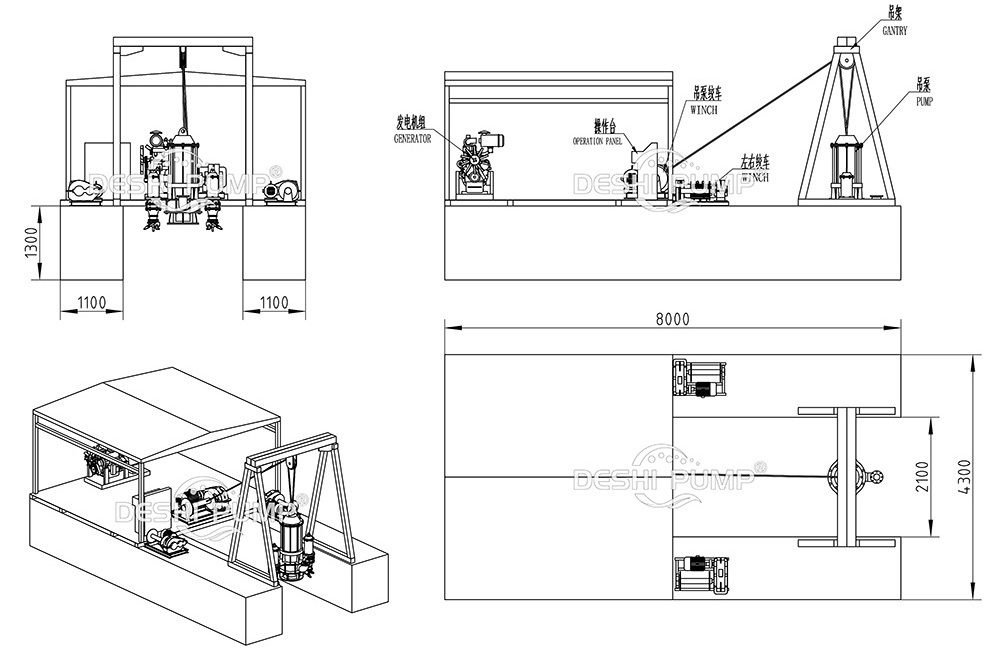

Arrangement Drawing example:

Details

Shipping

Introduction of Submersible Sand/Slurry pump:

The ZJQ series submersible slurry pump is specially designed for slurry, sand, tailings, dredging, sludge, sewage, and sediment in sewage treatment work, etc., where the motor and the pump are coaxially submerged in medium. The pump flow parts are constructed from high-chrome alloy, wear-resistant material, guaranteeing an extended work life and accommodation of large flow volumes.

In addition to the main impeller, the bottom of the sludge pump includes a set of agitation reamer that can work the deposited sludge into turbulent flow, increasing the concentration without need of an auxiliary device. The unique sealing device can effectively balance the pressure inside and outside of the oil chamber for maximum protection. The motor was designed with many safety features including, protection from overheating, water inlet detecting projections, and an ability to operate safely for long periods of time in harsh working conditions. The side attached agitator is optional to increase pumping efficiency.

Assembly Structure:

Overview:

| Model | ZJQ |

| Discharge Dia.(mm) | 65-450 |

| Flow Rate(m³/h) | 25-2500 |

| Lift/Head(m) | 12-90 |

| Motor power(KW) | 5.5-400 |

| Rotating speed(rpm) | 960/1450 |

| Max. Allowable Solid size(mm) | 14-82 |

| Seal type | Mechanical Seal |

Advantage:

1. Mechanical seal and excellent water-proof technology make sure safe and stable running under water.

2. Equipped with bottlom agitator, nice stirring effect, and operation is easy.

3. Good suction lift performance with much higher efficiency

4. No need to equip with vacuum pump, and help clients to save cost.

5. It is not required to build the complicated ground protection and fixing device when the motor is submerdged under water, which is simple and convenient.

6. The bottom agitator directly contacts the sediment surface, and slurry density can be controlled by

the submerged depth.

7. All the wear parts are made of ultra chrome alloy, the service life is longer.

Typical Application:

|

• Mineral processing |

• Mining |

• Coal Washery |

• Cyclone feeds |

|

• Aggregate |

• Chemical slurr y |

• Tailing |

• Mill grinding |

|

• Ash handing |

• M etallurgy |

• Waste sludge |

• Coarse sand |

|

• Sand |

• Phosphoric acid |

• Dredging |

• Sewage |

|

• Quarry |

• Power Plant |

• Fertilizer |

• Tunnel |

|

• Iron ore sand |

• Copper Concentration |

• Gold mine |

• Molybdenum |

|

B entonite |

Construction |

Island Reclaiming |

Alumina Industry |

Pump Model Meaning

Perameters Table:

Stirring Effect and Installation View

Submersible slurry pump Application Scenarios

Please contact us for the detailed outline drawings if needed.

Assembly Workshop & Stock

Testing Center

Packaging & Shipping:

Applications Case:

Our main products:

Note: The displayed prices are for reference only, and the final price should be subject to mutual negotiation.

Welcome to contact us any time for more details.

Your inquiry or advice will get our prompt attention and response !

Hot Searches