NaN / 0

Top quality automatic 500ml bottle butter filler capper honey fruit jam filling capping machine

Get Latest Price

US$ 12000

≥1 Sets

US$ 11000

≥3 Sets

Quick Details

Machinery Capacity:

2000BPH, 1000BPH

Packaging Material:

Wood

Filling Material:

Milk, Water, Oil, Juice, butter, jam

Filling Accuracy:

≥99.5%

Product Details

Product Description

YMF4C1 Top quality filler 500ml bottle butter honey filling capping machine

one machine two function, cheaper

Functions:

1. Adopt 316L stainless steel piston pump in common use in special use to fill high precision, large range of adjusting dosage.

2. Low level liquid receiver ,be convenient to clean.

3. Not fill without bottle, automatic stop as no drop leak

4.F illing system has the function of shrinking ,no drop leak

5.Apply to fill various kinds of viscosity.

6.Filling nozzles is diving into bottle to fill and moving up slowly, avoid bubbling

7.Filling and capping are in one body of bottle to the machine, economical and low space possessing.

8.The whole machine is designed according to requirements of GMP.

Technical parameter:

|

Applied bottle volume |

10-1000ml |

|

Tolerance of filling quantity |

≤±0.5% standard filled quantity |

|

Yield of cap-rotating |

≥99.9% |

| Power supply |

380V/220V 50Hz |

|

Power

|

2KW |

|

Single machine noise |

≤70dB |

|

Weight |

approx. 8 00kg |

|

Overall dimension |

(L*W*H) 2500*1000*2000mm |

|

Production capacity(500ml) |

1200-2400bottles/hour |

FAQ

Q1: Are you a factory or a trading company?

We are a factory specializing in the production of packaging machinery

Q2:How long is the delivery date?

The delivery date is about 15-40 working days

Q3:What is payment term?

Deposit 30% in advance and 70% before shipment the machine.

Q4: How can you guarantee quality?

1,We will test strictly after the machine is completed

2,Our machine are certified by SGS

3,Our different workers are responsible for different production processes to ensure that everyone's work is in place

4,We have our own inspection team. The inspectors will operate and test after the machine is completed

5,So far, our company has not had a single quality complaint, and the customer satisfaction is 100%

Q5:How can I know your machine is designed for my product?

You can send us samples of your product and we test it on machine,and take care of your all needs

Q6:Is there any installation direction after we received the machine?

Yes, of course,and we have a professional technical team and warm after service.

and We can solve any problem you meet during the installation and packing production in time.

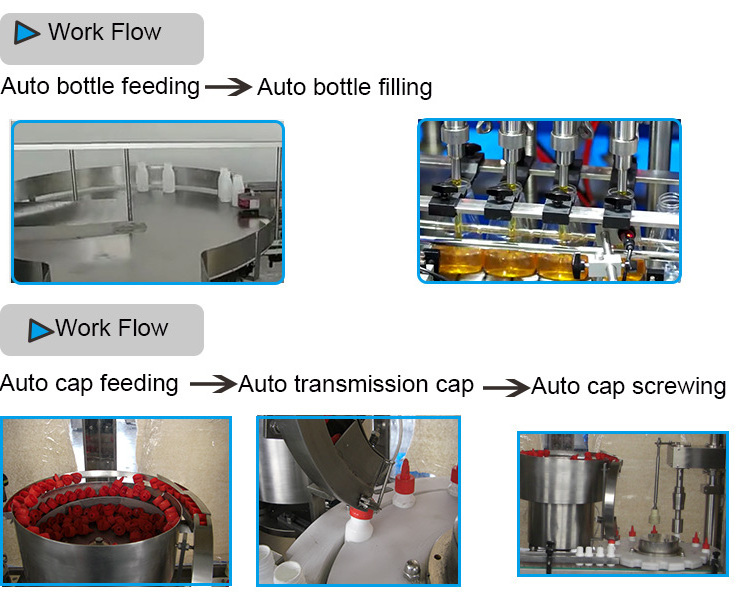

production process

Yimu team

Certifications

Hot Searches