NaN / 0

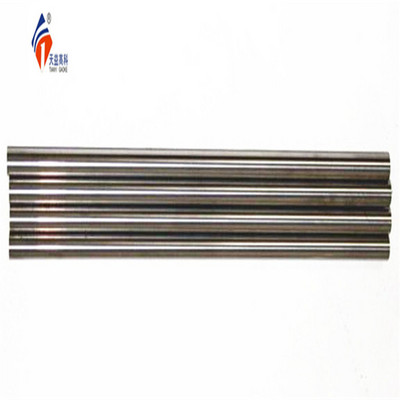

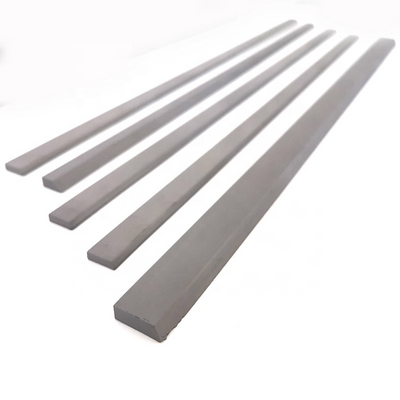

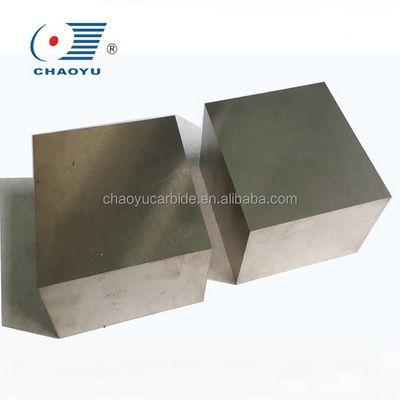

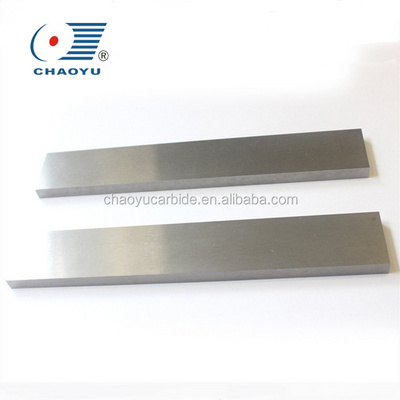

Tungsten Carbide Button Tungsten Carbide Cube Tungsten Carbide Wear Parts

Get Latest Price

US$ 20

≥1 Kilograms

Quick Details

Place of Origin:

China

Brand Name:

Chaoyu

Model Number:

tungsten Carbide Cube

Material::

tungsten carbide,heavy alloy,pure tungsten

Product Details

Tungsten Carbide Button Tungsten Carbide Cube Tungsten Carbide Wear Parts Features

1. Excellent quality and reasonable price

2. 100% raw material

3. Good abrasion, heat and corrosion resistance

4. Various size and shape, grade K20(YG6), K30(YG8), YG3X(K01),YG15, YG20,YT15(P10),YW1(M10)

Tungsten Carbide Button Tungsten Carbide Cube Tungsten Carbide Wear Parts Application

They

are used for cutting metal, wood, works as wear parts, also used for

prescision punching and high speed punching, such as inserting plugs, motor rotors, El silicon slices,etc. industries of electronics, IC and semi-conductors, etc.

We produce tungsten button/cube/wear parts in different sizes and qualities. We accept orders of all Types of special products designed for our customers.

Tungsten Carbide Button Tungsten Carbide Cube Tungsten Carbide Wear Parts Grade Information

|

Grade |

Density g/cm 3 |

TRS N/mm 2 |

Hardness(HRA) |

Application recommended |

|

YF10.1 |

14.80—15.15 |

≥1880 |

≥91.0 |

High hardness and wear resistance, suitable for high speed wire drawing mould, cutting tools, rod, wear-resistant parts, etc. |

|

YF10.2 |

14.30—14.65 |

≥2430 |

≥91.8 |

Have high comprehensive performance, widely used in electronics, metal, wood, bamboo, etc tool. Can also be used in high-quality wear-resistant parts field. |

|

YL80 |

13.75—14.05 |

≥3200 |

≥89.5 |

High hardness and toughness, suitable for producing the electronics industry and stamping mould plate. |

|

YL80.1 |

14.70—14.90 |

≥2020 |

≥89.5 |

High abrasion resistance, used in powder metallurgy mould etc. |

|

YL80.2 |

14.00—14.20 |

≥2900 |

≥86.5 |

Suitable for making stamping die for small and medium-sized watch parts and musical Instruments; cutting tools for roller and plate shearer. |

|

YL80.3 |

13.50—13.80 |

≥2540 |

≥85.0 |

Suitable for making carbide plate as punching tool under high stress. |

|

YL90 |

13.50—13.70 |

≥2500 |

≥82.5 |

High strength and toughness, suitable for making large size reducing die, Performance better thanYG20C. |

|

YL90.1 |

13.90—14.10 |

≥2340 |

≥84.5 |

High wear resistance and toughness, suitable for making general impact resistance forging die, cold and heading die |

|

YL90.2 |

13.70—13.90 |

≥2400 |

≥83.0 |

Middle size Bolt shrink neck mode |

|

YL90.4 |

13.20—13.40 |

≥2600 |

≥82.0 |

High strength and anti-fatigue toughness, used to have greater impact cold mound, cold blunt, punching mould |

|

YL90.5 |

13.00—13.20 |

≥2760 |

≥81.0 |

Good impact resistance, fatigue resistan,used for high loading punching die |

|

YL90L |

13.20—13.40 |

≥2550 |

≥81.5 |

Used for general cold screw scissors die and cutting shear blade tips |

|

YG6A |

14.80—15.10 |

≥1580 |

≥91.5 |

Suitable for semi-finishing of cast, nonferrous metal and low-alloy steel. Fine grain, for drawing dies and woodworking tools |

|

YG6X |

14.70—15.10 |

≥1600 |

≥91.0 |

Suitable for drawing dies to draw steel wire, on-ferrous wire and rods with small diameter at a high speed |

|

YG6 |

14.70—15.05 |

≥1670 |

≥89.5 |

Suitable for drawing dies to draw steel wire, on-ferrous wire under a diameter of 20mm and tubes under a diameter of 10mm |

|

YG8 |

14.60—14.8 |

≥1840 |

≥89 |

Suitable for drawing dies to draw steel wire, on-ferrous wire and alloy rods, tubes, also for making wear parts, tools(such as muzzles, grinders, drills ect.) |

|

YG15 |

13.90—14.20 |

≥2700 |

≥86.5 |

Suitable for drawing dies to draw steel rods and tubes at a high compression ratio, Medium grain, for mining tools, cold heading and punching dies |

|

YG20 |

13.40—13.70 |

≥2480 |

≥84.5 |

Medium grain, for non-standard dies and moulds, cold heading and punching dies |

Product Description

Main Produts

Hot Searches