NaN / 0

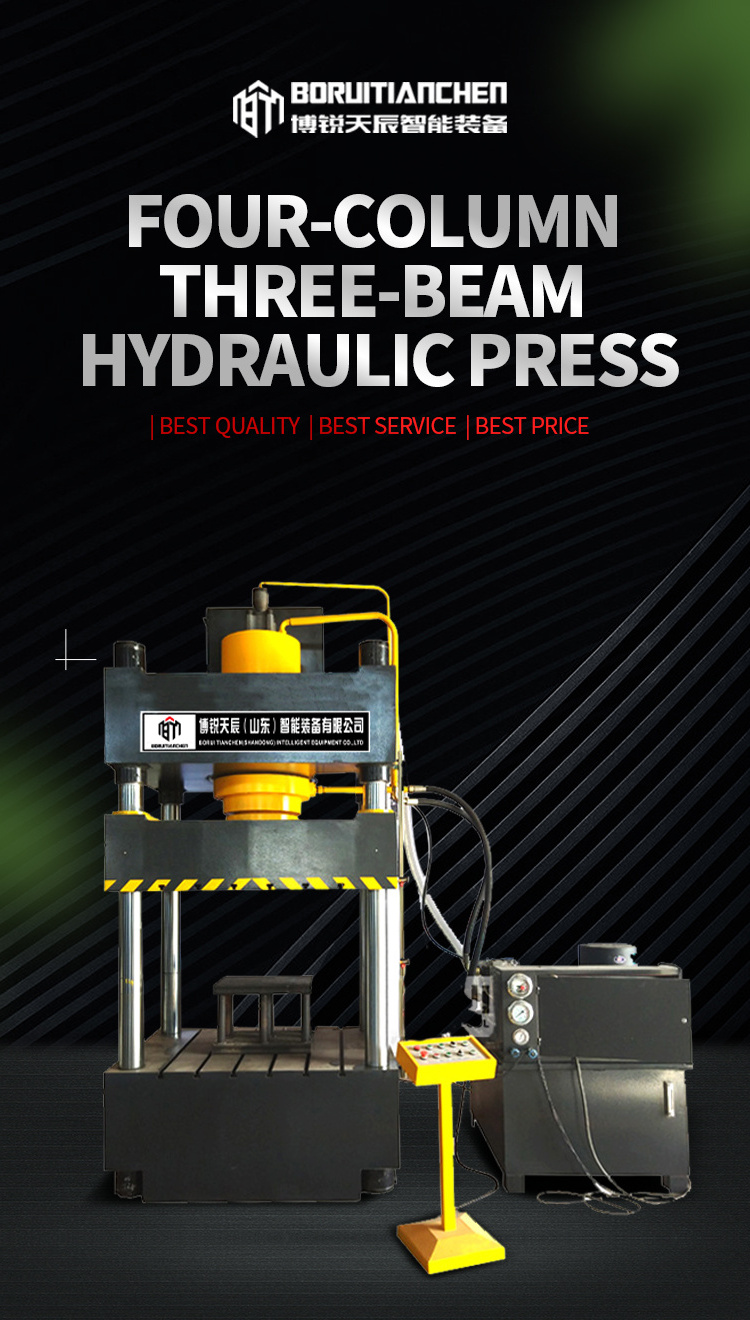

Customized High Speed 500 Ton Hydraulic Press Four Column Hydraulic Press Machine 200 Ton

Get Latest Price

US$ 8999

≥1 Sets

US$ 6999

≥5 Sets

Quick Details

Machine Type:

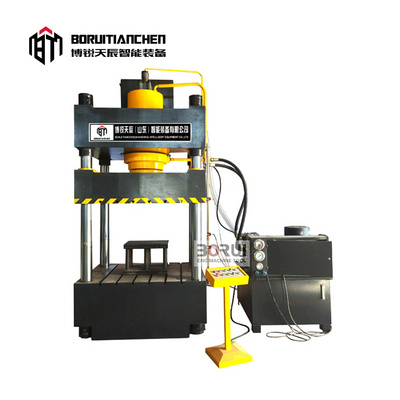

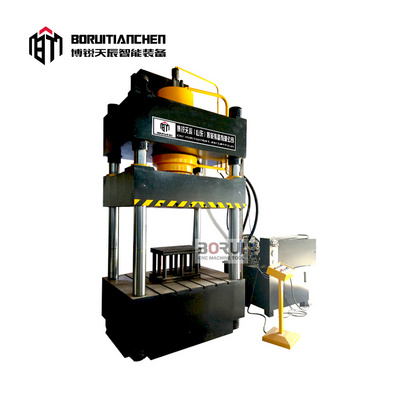

Four-column Three-beam Hydraulic Press

Slide Stroke (mm):

300, 400, 500, 600, 700, 800

Ejector Force (kN):

200

Return Force (kN):

300 kN

Product Details

Customized High Speed 500 Ton Hydraulic Press Four Column Hydraulic Press Machine 200 Ton

Products Description

Main Characteristic

1. This press is suitable for processing metal materials, such as stamping, bending, cramping and drawing metal sheet, ect. It can also be used for straightening, pressing, plastics molding and sintered parts compacting.

2. It is suitable for the press fitting and stretch forming of metal and plastic products as well as the movements of coining and overprinting.

3. The press has its own independent dynamic mechanism and electric system and uses pushbuttons controlling system.

4. Three operation modes of adjustment, manual and semi-auto operations can be realized.

5. It employs four-column guiding device and ejecting device, which can automatically eject work pieces with accurate guiding and fast speed. The drawing device can be added to this equipment in order to change molds easily.

6. The new generation servo driven hydraulic press is basis of servo motor driven technology.

7. The equipment adopts servo motor control. It will save 30%-50% of energy and the noise is smaller than normal motor.

8. Working position, speed, pressure can be adjusted and save in the touch screen with no limit.There are safety light curtains both on the front and back of the press

9. The hydraulic oil temperature rising slowly even though machine has long working hours. The oil temperature will rise 5-10°in 8 hours of continuous working environment.

10. Pipes and joints are all imported cutting ferrule of joints and precision galvanized steel pipe.

11. PLC programming. Setting, saving and modifying parameters on touch screen.

12. The working stroke control and main cylinder pressure adopts the GEFRAN displacements sensor( ITALY brand) and pressure sensor to set the upper limit position, the fast and slow speed limit, the lower limit position and pressure

1. This press is suitable for processing metal materials, such as stamping, bending, cramping and drawing metal sheet, ect. It can also be used for straightening, pressing, plastics molding and sintered parts compacting.

2. It is suitable for the press fitting and stretch forming of metal and plastic products as well as the movements of coining and overprinting.

3. The press has its own independent dynamic mechanism and electric system and uses pushbuttons controlling system.

4. Three operation modes of adjustment, manual and semi-auto operations can be realized.

5. It employs four-column guiding device and ejecting device, which can automatically eject work pieces with accurate guiding and fast speed. The drawing device can be added to this equipment in order to change molds easily.

6. The new generation servo driven hydraulic press is basis of servo motor driven technology.

7. The equipment adopts servo motor control. It will save 30%-50% of energy and the noise is smaller than normal motor.

8. Working position, speed, pressure can be adjusted and save in the touch screen with no limit.There are safety light curtains both on the front and back of the press

9. The hydraulic oil temperature rising slowly even though machine has long working hours. The oil temperature will rise 5-10°in 8 hours of continuous working environment.

10. Pipes and joints are all imported cutting ferrule of joints and precision galvanized steel pipe.

11. PLC programming. Setting, saving and modifying parameters on touch screen.

12. The working stroke control and main cylinder pressure adopts the GEFRAN displacements sensor( ITALY brand) and pressure sensor to set the upper limit position, the fast and slow speed limit, the lower limit position and pressure

Product main technical parameters:

|

Type

|

Unit

|

100T

|

160T

|

200T

|

315T

|

500T

|

630T

|

1000T

|

2000T

|

|

Nominal Pressure

|

KN

|

1000

|

160

|

2000

|

3150

|

5000

|

6300

|

10000

|

20000

|

|

Ejecting Force

|

KN

|

200

|

250

|

400

|

630

|

1000

|

1000

|

1000

|

2000

|

|

Max.working pressure

|

Mpa

|

26.2

|

26

|

25

|

25

|

26

|

26

|

26

|

27

|

|

Slide stroke

|

mm

|

500

|

500

|

700

|

800

|

900

|

900

|

900

|

1400

|

|

Max.opening height

|

mm

|

900

|

900

|

1120

|

1250

|

1500

|

1500

|

1500

|

1600

|

|

Table Size(F.B.)

|

mm

|

580

|

800

|

900

|

1200

|

1400

|

1500

|

1600

|

2000

|

|

Table Size(L.R.)

|

mm

|

710

|

800

|

900

|

1200

|

1400

|

1500

|

1600

|

2800

|

|

Ejecting stroke

|

mm

|

200

|

200

|

250

|

300

|

300

|

400

|

400

|

450

|

|

Idle stroke

|

mm/s

|

100

|

100

|

100

|

>100

|

>100

|

>100

|

>100

|

>100

|

|

Pressing

|

mm/s

|

8-15

|

8-15

|

8-15

|

8-15

|

10

|

10

|

12

|

10

|

|

Return

|

mm/s

|

60

|

60

|

70

|

70

|

65

|

65

|

80

|

>75

|

|

Power of motor

|

KW

|

7.5

|

15

|

18.5

|

22

|

45

|

45

|

68

|

134

|

|

Total Weight

|

T

|

4

|

7

|

12

|

15

|

25

|

30

|

48

|

145

|

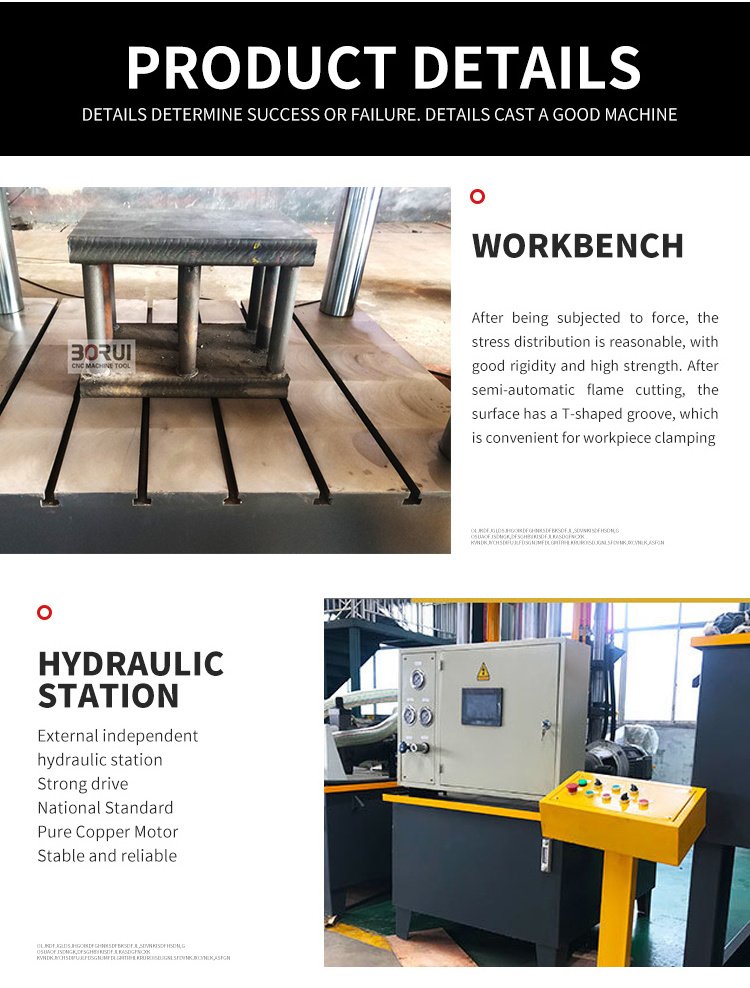

Details Display

Recommend Products

Hot Searches