NaN / 0

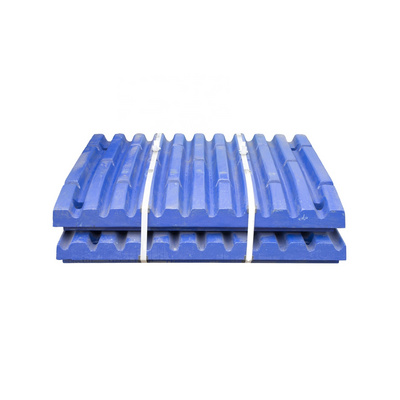

Mn13cr2 Jaw Crusher Wear Parts Manganese Steel Spare Parts Movable Tooth Plate

Get Latest Price

US$ 1388

≥1 Tons

Quick Details

Weight (KG):

1000

Place of Origin:

China

Brand Name:

XKJ

Product name:

JAW PLATE

Product Details

Product Description

A set of jaw plates is composed of the movable (swing jaw) and fixed (stationary) jaw plates. The crushed material in a jaw crusher is compressed when the movable jaw presses the feed material against the fixed jaw. The rock remains in the crushing chamber until it is small enough to pass through the gap towards the bottom of the jaws.

Jaw plates or jaw dies are the most frequently replaced wear parts of a jaw crusher, so the quality of the jaw plates is one of the most important factors that determines the crushing efficiency and machine operating time.

A set of jaw plates is composed of the movable (swing jaw) and fixed (stationary) jaw plates. The crushed material in a jaw crusher is compressed when the movable jaw presses the feed material against the fixed jaw. The rock remains in the crushing chamber until it is small enough to pass through the gap towards the bottom of the jaws.

Jaw plates or jaw dies are the most frequently replaced wear parts of a jaw crusher, so the quality of the jaw plates is one of the most important factors that determines the crushing efficiency and machine operating time.

FAQ

1. How long is the delivery time of your machine?

The delivery time is within 20-30 working days. But if the project is very large and clients have some special requirement about the equipment, the delivery time will be extened.

2.What are the payment terms?

The payment terms are L/C, T/T, D/A, D/P and other.

3.What is the minimum order quantity of your machine?

1 set. Our service will be to satisfy the needs of every client.

4.How long is the warranty period about machine?

Our machine warranty period is 1 year. Wearing parts and problem coursed by worker's wrong operation are not included.

5.What is the after sale service of your company?

We will provide foundation drawing to the clients for installation. Besides, we can provide installation service, workers training service, etc.

6.Can you provide wearing parts?

We have four casting factories that specialize in producing wearing parts for our clients. If your machine are not manufactured by our company, please provide us the wearing parts drawing.

7.Can you provide me a solution and quotation?

Of course. Please give us your details about project, raw material, the capacity, max feeding size, the output size, the usage of final products, etc.

Technical Parameter

|

Material |

Chemical Composition(%) |

Mechanical Property |

||||

|

|

C |

Si |

Mn |

Cr |

AK/cm |

HB |

|

Mn13Cr2 |

1.1-1.4 |

1.7-2.2 |

12-15 |

1.7-2.2 |

>140 |

≤ 220 |

|

Mn18Cr2 |

1.1-1.4 |

1.7-2.2 |

17-19 |

1.8-2.2 |

>140 |

≤ 230 |

Our Services

Pre-sale service:

(1) Professional technicians provide customers with suggestions for model selection.

(2) Design and manufacture machines according to customers' special requirements.

After-sales service:

(1) Arrange technicians to guide the installation.

(2) If your machine is out of warranty, you can buy spare parts from us at the best price.

(3) Engineers can repair machines overseas.

Detailed Images

|

Name |

Jaw plate, swing jaw plate, fixed jaw plate, toggle plate,movable jaw,fixed jaw,jaw crusher jaw |

|

M aterial |

Mn13Cr2( M1 equivalent grades),Mn18Cr2(M2 equivalent grades) |

|

Control |

Spectrometer chemical analysis and control while producing |

|

Molding Process |

Water-glass sand casting or lost form casting |

|

Melting Facility |

Medium frequency electric furnace |

|

Heat Treatment |

Anneal, quenching, tempering |

|

Quality Guarantee |

One year against manufacturing defeat |

|

Testing |

Hardness, flaw detector test |

|

Certificate |

ISO9001~2008 Passed; BUREAU VERITAS |

|

Application |

Cement firms, coal fired power plant ,mining firms ,metallurgy ,quarry firms |