NaN / 0

Plaster Glue Super Waterproof Packing Adhesive Tape

Get Latest Price

US$ 1.08

≥36 Rolls

Quick Details

Adhesive:

Rubber

Adhesive Side:

Single Sided

Adhesive Type:

Pressure Sensitive

Design Printing:

Offer Printing

Product Details

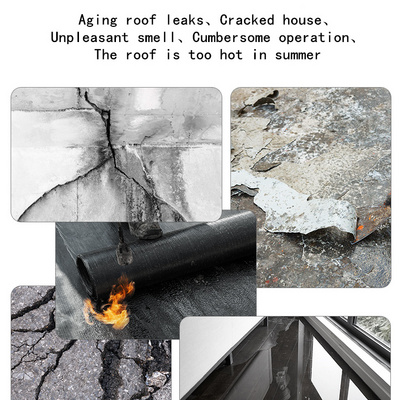

Waterproof sealing tape, Repair leaks in roofs, glass windows, and exterior walls, etc.

Butyl waterproof sealing tape is made by blending butyl rubber and polyisobutylene and other main raw materials. According to special production formula, adopting new blending vulcanization technology, selecting high-quality polymer materials, and producing environmental protection through a special process Solvent-free sealing and bonding material

Product Description

Specification

|

Test items

|

National standard

|

Our standard

|

||

|

Sticky duration

|

≥20min

|

≥30min

|

||

|

Adhesive strength under shear

|

≥2.0N/mm

|

≥4.8N/mm

|

||

|

Peel strength

|

≥0.6N/mm

|

≥1.0N/mm

|

||

|

Paste on the color steel plate 80℃, 168H

|

Peel strength retention rate≥80%

|

≥100

|

||

|

Low temperature,-40℃

|

No cracks, flexible

|

No cracks, Flexible

|

||

|

Stick to the color steel plate and soak in strong alkali solution for 168H

|

Peel strength retention rate≥80%

|

≥100

|

||

|

Adhere to cement mortar board soaking water treatment

|

Peel strength retention rate≥80%

|

≥98

|

||

|

The above data inspection is based on the domestic butyl rubber production standard "JC/T942-2004 Domestic Building Material Testing Standard"

|

|

|

||

|

Product Features:

|

|

|

||

|

1.Reliable application performance: its adhesion, water resistance, airtightness, high and low temperature resistance are excellent,and dimensional stability is good.

|

|

|

||

|

2.Stable chemical properties: excellent chemical resistance, weather resistance and corrosion resistance.

|

|

|

||

|

3.Excellent mechanical properties: high bond strength, high tensile strength, good elasticity and extension properties, strong adaptability to interface deformation and cracking, and excellent follow-up to the deformation of objects.

|

|

|

||

|

4.The construction operation process is simple.

|

|

|

||

|

|

|

|

||

|

Product main application:

|

|

|

||

|

1.Sealing, waterproofing, and shock absorption at the joints of colored profiled panels, cement, glass roofs, iron sheets, and cracks in external walls. Leaking cracks in tiles, drain pipes, containers, etc.

|

|

|

||

|

2.Waterproof treatment of roof waterproofing, underground waterproofing, structural construction joints and lap joint sealing of polymer waterproofing membranes for newly-built projects.

|

|

|

||

|

3.Sealing and waterproofing treatment of construction joints of subway tunnel structure in municipal engineering.

|

|

|

||

|

4.Adhesive sealing and waterproof treatment in automobile assembly.

|

|

|

||

|

5.Waterproof and sealing treatment of joints in steel structure construction.

|

|

|

||

|

6.It is suitable for waterproofing and sealing all kinds of civil roofing, color steel, steel structure, waterproof coiled material, PC board, etc. under sunlight. At the same time, it can be used as heat insulation

|

|

|

||

|

7.Other application scenarios for sealing and waterproofing, shock absorption and heat insulation, etc.

|

|

|

||

|

|

|

|

||

|

Construction Notes:

|

|

|

||

|

1.The construction environment needs to be constructed within the temperature range of -15°C~45°C (corresponding measures should be taken when the specified temperature range is exceeded),It is recommended that the temperature of the base surface should be kept above 5°C for the best bonding effect

|

|

|

||

|

2.The surface of the base layer must be cleaned or wiped clean, kept dry and free of dust and oil.

|

|

|

||

|

3.The bonding area cannot be torn or peeled within 24 hours after construction.

|

|

|

||

|

4.Do not use it at the same time with other waterproof materials containing organic substances such as benzene, toluene, methanol, ethylene, silica gel, etc.

|

|

|

||

|

5.Waterproof sealing single-sided tape, the aluminum foil surface is the water facing surface (that is, the water flows on the surface of the aluminum foil), and the adhesive surface is attached to the crack

|

|

|

||

|

6.Choose butyl sealing tapes of different types and sizes according to actual engineering needs. You can contact us to recommend the most suitable waterproof sealing tape

|

|

|

||

|

7.If you have any questions or unclear points, please feel free to contact us for consultation

|

|

|

||

Hot Searches