NaN / 0

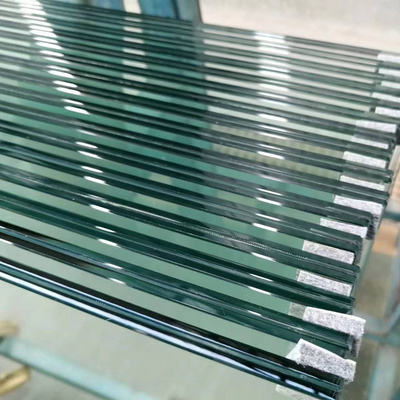

6.38mm 8.38mm Clear PVB laminated tempered glass

Get Latest Price

US$ 4.5

≥200 Pieces

US$ 3

≥1000 Pieces

US$ 1.5

≥5000 Pieces

Quick Details

Application:

Home Office, Hotel

Usage:

Industrial, Decoration, Bulletproof, Instrument

Thickness:

4-19mm, 4-19mm

Place of Origin:

Guangdong, China

Product Details

|

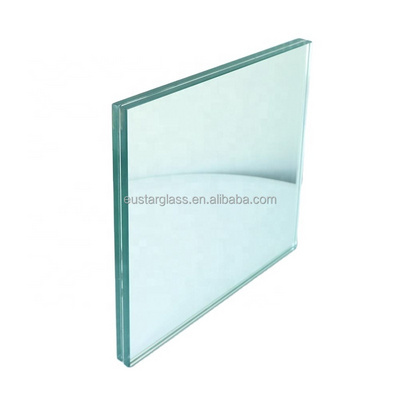

Product Type

|

Laminated tempered glass

|

|

|

|

|

|

|||||

|

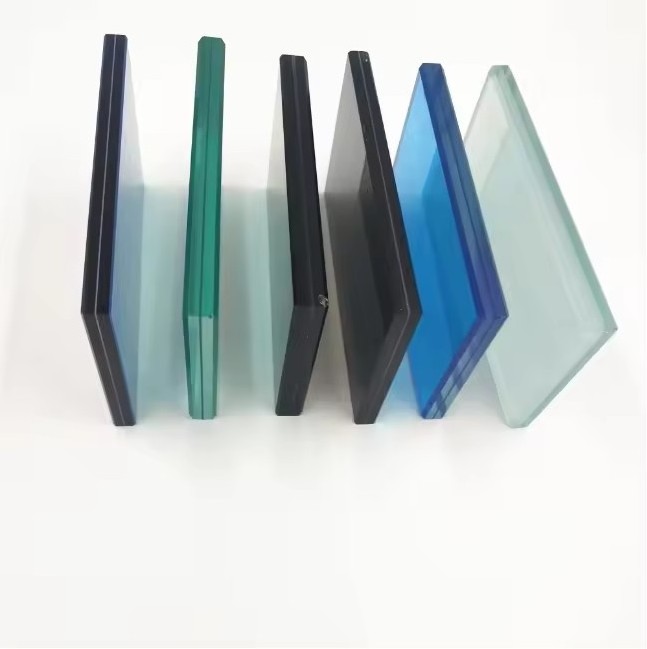

Glass Material

|

Soda lime glass/Aluminosilicate glass/Low Iron glass/Borosilicate glass

|

|

|

|

|

|

|||||

|

Size

|

Size can be customized

|

|

|

|

|

|

|||||

|

Thickness

|

4-19mm

|

|

|

|

|

|

|||||

|

Tempered

|

Thermal Tempered/Chemical Tempered

|

|

|

|

|

|

|||||

|

Edge treatment

|

CNC grind, polished, chamfered

|

|

|

|

|

|

|||||

|

Hole

|

Round/Square (Irregular hole are available)

|

|

|

|

|

|

|||||

|

Color

|

Black/White/Silver (up to 7 layers of colors)

|

|

|

|

|

|

|||||

|

Printing Method

|

Normal Silkscreen printing/High Temperature Silkscreen printing

|

|

|

|

|

|

|||||

|

Coating

|

Anti-Glaring

Anti-Reflective Anti-Fingerprint Anti-Scratches |

|

|

|

|

|

|||||

|

Production Process

|

Cut-Edge Polish-CNC-Clean-Tempered-Print-Clean-Inspect-Pack

|

|

|

|

|

|

|||||

|

Features

|

Anti-scratches/Waterproof/anti-fingerprint/anti-fire/easy to clean/high-pressure scratch resistant

|

|

|

|

|

|

|||||

Glass panel application:

Product Description

Anti glare glass

AG glass, also known as anti-glare glass, is the glass surface through single-side or double-side specialized treatment to form

fine concave and convex particles, achieve the effect of multi-angle diffuse reflection, reduce the incident light reflection rate

from 8% to below 2%, eliminate glare problem, improve visual comfort.It mainly used in vehicle display, TV splicing wall, flat screen TV, LCD display, touch screen, industrial instrument and picture

frame display fields.

Type of AG process

1. Spraying AG, It is to spray a layer of optical astigmatism particles on the surface of glass, when this coating is formed, it

can achieve anti-reflection and anti-glare effect.2. AG coating, It is through the atomization coating technology to cover the specific coating materials on the surface of the

glass, the role of these coating materials is to selectively combine the light, with the effect of absorption and deflection of

light pointing, in order to achieve the effect of anti-radiation and anti-glare.

3. Acid etched AG, It is the most commonly used AG process in the glass deep processing industry. The process is through the mixed

acid preparation with HF acid as the main agent, the glass body is etched by chemical reaction. After etching, the glass surface

will change from a reflective surface to a matte diffuse surface.

What is safety glass?

Tempered or toughened glass is a type of safety glass processed by controlled thermal or chemical strengthened to increase its strength compared with normal glass.

Tempering puts the outer surfaces into compression and the interior into tension.

Tempered or toughened glass is a type of safety glass processed by controlled thermal or chemical strengthened to increase its strength compared with normal glass.

Tempering puts the outer surfaces into compression and the interior into tension.

Edge & Angle & Shape Work

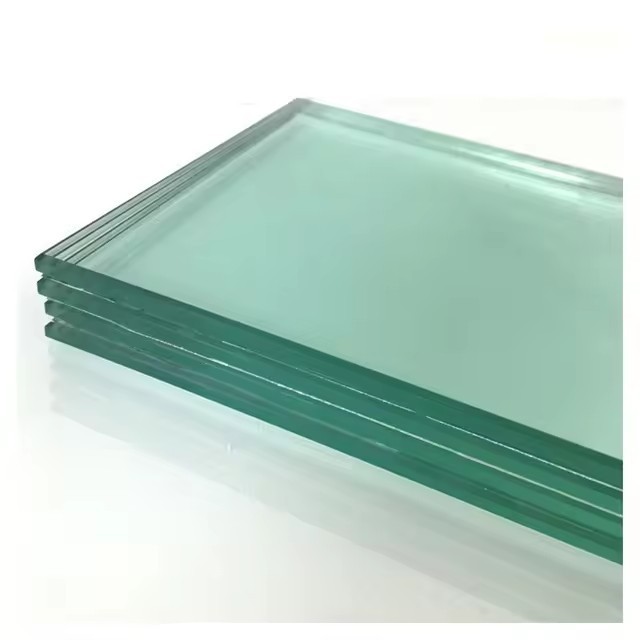

Packing & Delivery

double side protective film,

wraped by kraft paper,

then in Polywood crates.