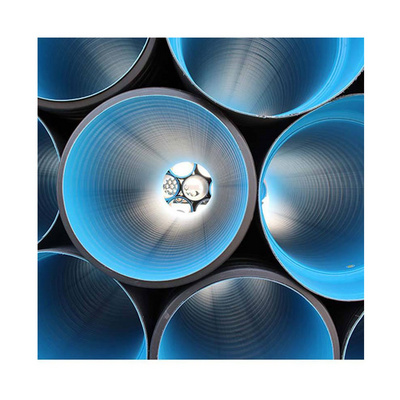

HDPE double-wall corrugated pipe is a lightweight pipe made of high-density polyethylene. It has the characteristics of new light

weight, high pressure resistance, good strength, fast construction, long service life, etc. Its excellent pipe wall structure

design, and other structures Compared with pipes, the cost is greatly reduced. And because of its convenient and reliable

connection, it was widely used in the first half of the year. Massive replacement of concrete pipes and cast iron pipes.