NaN / 0

Aluminum Press die casting Zinc cast die casting Tooling

Get Latest Price

US$ 2

≥500 Pieces

Quick Details

Place of Origin:

Shandong, China

Brand Name:

SEGER

Model Number:

SE009

Material:

Aluminum

Product Details

Products Description

|

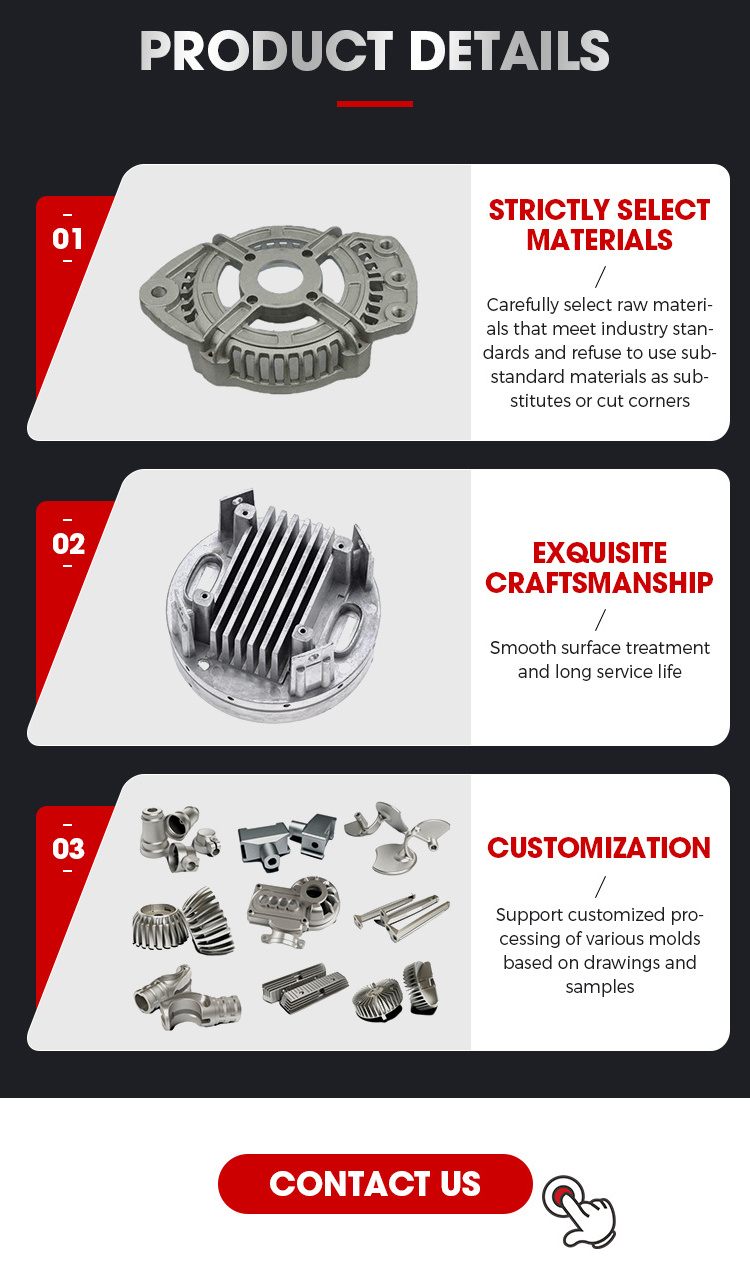

Technic

|

Die Casting

|

|

Material

|

Aluminum/Aluminum Alloy: USA Standard: A360,A380,A356,A383 etc.

Europe Standard: EN-AC46100,EN-AC46000,EN-AC47100 etc. Others: Zinc, Zinc Alloy, Brass etc. |

|

|

|

|

Process

|

Drawing/Sample-Quotation-Mould-Prototype-Die Casting-Deburring-Machining-Surface Finish-Quality Inspection-Packing-Shipping

|

|

Surface

|

Sandblasting,Painting,Powder Coating,Chrome Plating,E-coating,Anodizing

|

|

Application

|

Automotive,Building Industry,Furnitures,Train Braking System,Lighting, Home Appliance etc.

|

|

Mould Material

|

H13 steel, 2344 steel

|

|

Mould Cavity

|

1 cavity,2 cavities,4 cavities,8cavities

|

|

Mould Lifetime

|

50000-100000shoots

|

|

Quality Control

|

Surface, Dimensions,Threads,Balance, Gas Density,Material

|

|

Die Casting Machine

|

80-800ton

|

|

Part Weight Range

|

0.1-8kgs

|

|

Min Wall Thickness

|

3mm

|

|

Min. Tolerances

|

+/-0.02mm

|

Q1:

What is your MOQ?

A1: Our MOQ is 100 pieces.

Q2: Do you offer free sample?

A2: We can provide you a sample but you need to pay for it and also the freight .

Q3: What is your payment term?

A3: 30% down payment after confirming the contract/PI and the balance before shipment/copy of Bill of Lading .

Q4: What normal cooperation processes do you have?

First , we need your drawing for quotation .

Second , you accept our quotation , then you pay for the tooling cost and we will arrange to make the sample on approval .

Third , you approve with the sample and we make sales contract for you to confirm .

Fourth , manufacturing products and shipping to you .

Fifth , you pay us the balance .

Finally , you receive die cast mould and feedback .

A1: Our MOQ is 100 pieces.

Q2: Do you offer free sample?

A2: We can provide you a sample but you need to pay for it and also the freight .

Q3: What is your payment term?

A3: 30% down payment after confirming the contract/PI and the balance before shipment/copy of Bill of Lading .

Q4: What normal cooperation processes do you have?

First , we need your drawing for quotation .

Second , you accept our quotation , then you pay for the tooling cost and we will arrange to make the sample on approval .

Third , you approve with the sample and we make sales contract for you to confirm .

Fourth , manufacturing products and shipping to you .

Fifth , you pay us the balance .

Finally , you receive die cast mould and feedback .