NaN / 0

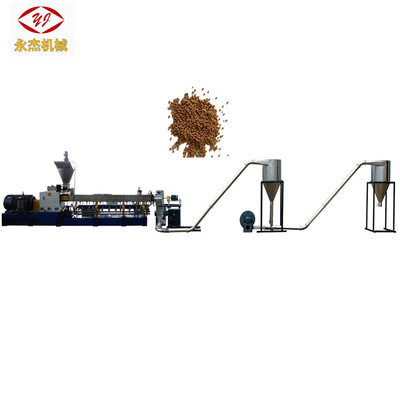

Twin Screw PP Wood Plastic Composite Extruding Pelletizing WPC Extruder Machine Price

Get Latest Price

US$ 46000

≥1 Sets

US$ 38000

≥3 Sets

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

40:1, 44:1

Screw diameter (mm):

71

Screw Speed (rpm):

500 rpm

Product Details

Product Paramenters

|

Model

|

Screw dia.

(mm)

|

L/D

|

Main power

(kw)

|

Screw speed

(rpm)

|

Capacity

(kg/h)

|

|

DMTA75

|

71

|

40-44

|

90/132

|

500-600

|

400-600

|

|

DMTA95

|

93

|

40-44

|

250

|

400-500

|

800-1000

|

Products Description

Features:

1.Screw components is completely self-cleaning type, with uniformed screw clearance and excellent mixing effect, can process

all kinds of polymer.

2.The flow channel of barrel is with special design of multi-channel, which can enhance the heat transfer capacity effectively

and improve the accuracy of the temperature control.

3.According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure, screw array,

venting number and location, feeding method, electrical control methods etc. for rational solution.

all kinds of polymer.

2.The flow channel of barrel is with special design of multi-channel, which can enhance the heat transfer capacity effectively

and improve the accuracy of the temperature control.

3.According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure, screw array,

venting number and location, feeding method, electrical control methods etc. for rational solution.

Process Flow Chart

Air cooling hot-face pelletizing line is widely used in wood plastic granulation and PVC modification,such as PE/PP+wood powder,

PVC+ CaCO3,etc.

It don’t contact with water during the whole pelletizing process,so this pelletizing system is more suitable for the materials

which is easy to absorb water,or not easy to be dewatered/dried, or its quality would be damaged by the moisture contant.

PVC+ CaCO3,etc.

It don’t contact with water during the whole pelletizing process,so this pelletizing system is more suitable for the materials

which is easy to absorb water,or not easy to be dewatered/dried, or its quality would be damaged by the moisture contant.

We can supply other different pelletizing system based on various raw materials and capacity requirements, which include water

cooling strand pelletizing line, water-ring hot-face pelletizing line, underwater pelletizing line,etc.

cooling strand pelletizing line, water-ring hot-face pelletizing line, underwater pelletizing line,etc.

Applications

We can customize solutions of granulating extruders and compounding system based on the different material and formula.Welcome to contact us for further discussion if you can’t find your application in below typical industry.

Hot Searches