NaN / 0

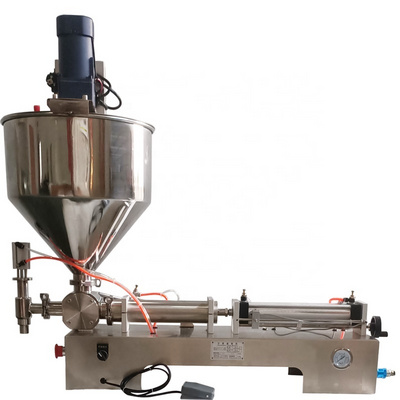

LIENM factory paste filling machine with mixing and heating cosmetic cream paste tube sealing machine

Get Latest Price

US$ 800

≥1 Sets

Quick Details

Machinery Capacity:

4000BPH, 8000BPH, 12000BPH, 6000BPH, 2000BPH, 1000BPH, OTHER

Packaging Material:

Paper, Wood

Filling Material:

Water, Other, Oil, OTHER, Cosmetics, perfumes, liquid soaps, creams, liquids

Filling Accuracy:

0.5g

Product Details

Product Description

Introduce

* 1. The appearance design of this series is beautiful and generous.

* 2. Use international famous brand electrical components.

* 3. The machine is easy to maintain and can be easily disassembled and cleaned without any tools. To adjust the measurement, you can adjust the measurement to a close range firstly and then fine-tune it. No filling when without bottles and lack of bottles. It has a high Accuracy in filling.

* 4. The filling system of the machine adopts the clamp type quick-fit sanitary joint. The entire cylinder can be easily disassembled and cleaned from top to bottom without tools.

* 5. the whole machine is designed according to GMP requirements.

* 1. The appearance design of this series is beautiful and generous.

* 2. Use international famous brand electrical components.

* 3. The machine is easy to maintain and can be easily disassembled and cleaned without any tools. To adjust the measurement, you can adjust the measurement to a close range firstly and then fine-tune it. No filling when without bottles and lack of bottles. It has a high Accuracy in filling.

* 4. The filling system of the machine adopts the clamp type quick-fit sanitary joint. The entire cylinder can be easily disassembled and cleaned from top to bottom without tools.

* 5. the whole machine is designed according to GMP requirements.

|

Technical Parameter

|

|

|

|

|||

|

Suitable bottle size:

|

Φ20—Φ100mm H30-100mm

|

|

|

|||

|

Production capacity:

|

20-30bottle/min

|

|

|

|||

|

Electric power:

|

≤0.8KW

|

|

|

|||

|

Filling volume:

|

5-150ml

|

|

|

|||

|

Required air pressure:

|

0.4-0.8Mpa

|

|

|

|||

|

Speed control:

|

control

|

|

|

|||

|

Machine weight:

|

260KGS

|

|

|

|||

|

Dimension :

|

L2500*W1600*H1450mm

|

|

|

|||

|

Material hopper:

|

normal one is 45L.

|

|

|

|||

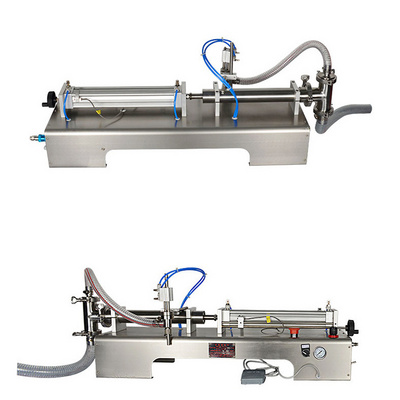

other types

Recommend Products

Company profile

Why Choose Us

Our factory

We have 2 factories, one was built in the year of 1983 at Jiangsu province, mainly produce mixing tanks.vacuum emulsiher and storage tanks, with 30 acres space and with pressure tank certifcate. Another wasbuilt in the year of 1996, mainly produce RO water purifer, flling packing lines, is with 5000 square meters

O

ur technology

2.1- We have 10 R & D experts, we design new machines every year and our experts study abroad everyyear, they are core of our company2.2- Our R & D is equip with file management system, we recorded programs for every customer

Our service

3.1- We can customize the machines according to customers demands;3.2- we can help customer to handle the whole process of producing daily cosmetic, from raw material,packages,decoration machines ETC:3.3- We have 10 engineers, they can fly to foreign countries to fix and install machines3.4- Our response is very fast, our sales team work dav and nicht, if you have anv guestions about themachines, they will reply you soon and give solution within 8 hours.3.5- Can help the formulation, packages and raw material problem3.6- Can test machine before place order

Our machines

4.1- Adopt high technology4.2- SS material is from china No 1 quality company4.3- Adopt famous brand of spare parts, such as Siemens, Schneider, ABBOmron.Panasonic ETC4.4- Working stable

Hot Searches