NaN / 0

Vertical Hydraulic carton paper cardboard press baler / Waste paper baling machine

Get Latest Price

US$ 2000

≥1 Sets

US$ 1800

≥5 Sets

Quick Details

Place of Origin:

Hebei, China

Brand Name:

Liheng

Voltage:

220V

Dimension(L*W*H):

900*650*2100mm

Product Details

Product Description

Products Description

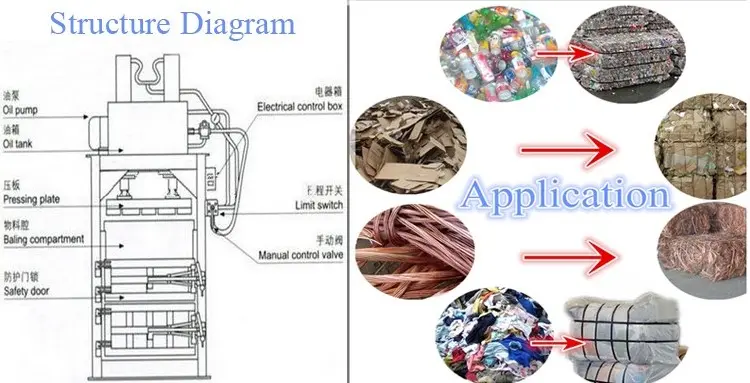

Vertical Hydraulic carton paper cardboard press baler / Waste paper baling machine

It is designed as vertical structure, two door opening ,hydraulic transmission, electrical control and manual binding.This series machines is mainly used for baling small material ,for example rice husk ,rice hull ,peanut shell,textile ,soft plastic cartons, cotton yarn, plastic. Usually the pressureforce of this series is from 60 ton to 80 ton, the efficiency is 4 ~ 6 pieces per hour. The weight of each piece is from 80 Kg to 120 Kg according to the material. Also, we can produce the machine according to the requirement from customer.

Features:

1.Adopting a hydraulic drive mechanism, Use less energy, with huge operating energy

2.Electric button control, it can reaches manual adjusting and semi automatic control.

3.Independent feeding opening with automatic pulling out installation, to reduce labor force.

4.It can be made according to the demands of customers, and the bale can be binded into "---" and "#" shape.

5.More safety, avoid the dangerous to operator.

Features:

1.Adopting a hydraulic drive mechanism, Use less energy, with huge operating energy

2.Electric button control, it can reaches manual adjusting and semi automatic control.

3.Independent feeding opening with automatic pulling out installation, to reduce labor force.

4.It can be made according to the demands of customers, and the bale can be binded into "---" and "#" shape.

5.More safety, avoid the dangerous to operator.

Application

Product packaging

Plastic film packaging machines. With wire and the machine is fixed to the container. When the container operations and surface bumps, the machine will not shake in the container.

Hot Searches