NaN / 0

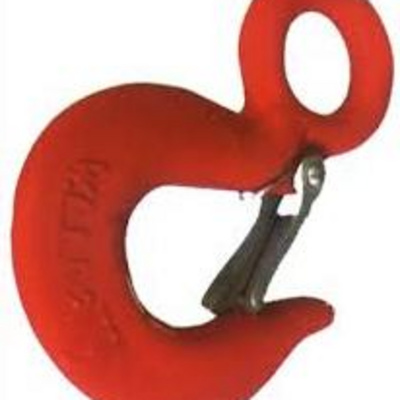

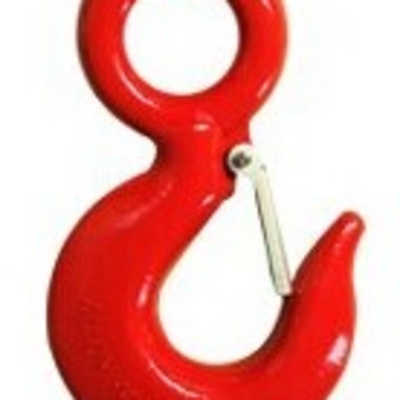

G80 Eye Hook with Latch Crane Safety Hook

Get Latest Price

US$ 0.2

≥1000 Pieces

Quick Details

Finish:

Plain, ZINC, Electrolytic Treatment

Application:

Heavy Industry

Material:

Alloy Steel

Model Number:

1

Product Details

Safety Hook

1. G80 Eye Hook with Latch Crane Safety Hook

a.Heat treated: drop forged, tempered and quenched

b.Material: Stainless steel 304 or 316,Carbon Steel,Alloy

c.Standard: EUROPEAN TYPE,JIS TYPE,US. TYPE,DIN TYPE

d.Size: 6-26 or accoring to customer's design

e. Surface: Hot dipped galvanized,Electro galvanized,Self-colored

2.Technical Parameter:

|

ITEM NO.mm |

WEIGHT/KG |

WLL/T |

B.L/T |

Φmm |

Emm |

Hmm |

Kmm |

Lmm |

|

6 |

0.28 |

1.12 |

4.48 |

19 |

22 |

19 |

80 |

110 |

|

7/8 |

0.65 |

2 |

8 |

28 |

25 |

25 |

103 |

140.5 |

|

10 |

0.94 |

3.15 |

12.6 |

31 |

27.5 |

28 |

118 |

162 |

|

13 |

1.95 |

5.3 |

21.2 |

39 |

33 |

35 |

145 |

201 |

|

16 |

3.77 |

8 |

32 |

51 |

40 |

45 |

180 |

256 |

|

20 |

6.8 |

12.5 |

50 |

62 |

51 |

57 |

230 |

317 |

|

22 |

9.8 |

15 |

60 |

73 |

57 |

70 |

260 |

360 |

|

26 |

16.25 |

21.2 |

84.8 |

89 |

75 |

76 |

318 |

434 |

3.Company Introduction

|

Qingdao YINGJUNDA Machinery Co., Ltd. |

|

|

ODM&OEM SERVICES |

|

|

Service |

Drawings or samples processing/OEM/ODM service provided |

|

Produce Process |

Drawings→ mould making → pre-forging →rough machining or finish machining →surface treatment →product checking and quality control→ packing →delivery |

|

Forging Material |

Carbon Steel, Alloy steel, Stainless steel |

|

Standard |

ISO, GB, ASTM, DIN, JIS |

|

Produce Equipment |

Friction Screw Press Series, CNC Lathe, Machining Center (Vertical Spindles), CNC Milling Machine, Bench Drilling Machine, Heat Treatment Equipments and so on. |

|

Surface treatment |

Hot dipped galvanized,Electro galvanized,Self-colored |

|

Inspection Equipments |

Metallurgical analysis, tensile strength tester, Hardness tester, Altimeter, Scale Micrometer, pressure tester, etc. |

|

Delivery |

Samples are sent by express Large quantity products delivered to customer by sea or according to your request |

|

Terms of payment |

T/T or L/C |

4.kinds of pictures

Qingdao YING JUNDA Machinery Co., Ltd. is a professional manufacturer of rigging hardware with well-equipped testing equipments and strong technical team. More than thirty five years, the company has been engaged in designing and making in shackles, turnbuckles, swivels, thimbles, hooks, bolt & nut, links, load binders, rings, wire rope clips, chains, winch & winch bar, steel cables and other rigging parts. Meanwhile, JING JUNDA accumulates extensive experience in rigging design and research and can provide OEM and ODM service. So far, the company built the largest scale manufacturing base for rigging hardware in Qingdao, China.

YING JUNDA factory covers an area of 18000 square meter s and occupies the most advanced testing equipments and quality-control system. There are about 300 working people and 3 production lines, which can meet bulk orders requirements and can make sure fast delivery time.

Relying on wide variety, good quality, novel designs, reasonable prices, fast delivery time and good service, bulk products have been purchased and extensively used in North America, Europe, Australia, Southeast Asia, South Asia, Central Asia, South America, Africa and other regions, and have been highly praised by customers around the world.