NaN / 0

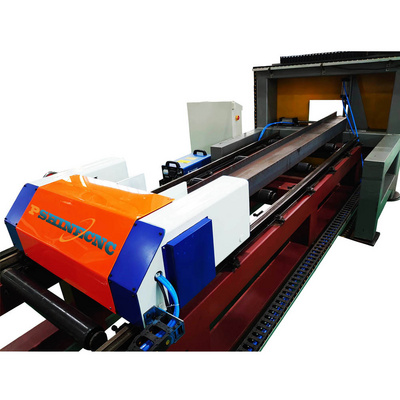

Factory price 5 x 10 plasma table diy cnc plasma cutter machine price

Get Latest Price

US$ 4500

≥1 Sets

Quick Details

Dimensions:

1300*2500mm

Place of Origin:

Shandong, China

Brand Name:

GoodCut

Model Number:

GC1325P

Product Details

Factory price 5 x 10 plasma table diy cnc plasma cutter machine price

Brief configuration of Factory price 5 x 10 plasma table diy cnc plasma cutter machine price:

1 X, Y axis adopt rack and pinion. X, Y axis orbit using precision linear compasses, effectively ensure the accurancy of machine operation.

2 Computer graphics, program production, control and processing seamlessly with a computer to achieve full fuctionality, save time, worry, and effort.

3 Mechanical limit, the electronic device to a set limit, so no worries production.

4 Bilateral drive, the configuration of high-power motor, fine points of the drive, with great precision mechanical actuation system, run faster, higher cutting efficiency.

Factory price 5 x 10 plasma table diy cnc plasma cutter machine price:

1--The unique means to increase the cutting wall, to avoid generating torch head sticking phenomenon and iron board contact rolling friction so run more smoothly, greatly improved cutting speed.

2--Using a dedicated duct expand software automatically generates drawings, export processing program. Operators need to do is select the desired software duct style, enter the desired size, and then export the machining program for cutting it, namely convenient, practical and accurate.

Factory price 5 x 10 plasma table diy cnc plasma cutter machine price

(1)Max cutting speed can reach to 10m per minute while precision keep withnin 0.3mm.

(2)Less and tidy incision ,no cutting slag or need of after treatment.

(3)High configuration for numerical control system ,stable performance.Automatic arc

striking can reach to 99% success rate.

(4)Adopting swift clamp to avoid workpiece moving and greatly reduce the cost.

Feature of Factory price 5 x 10 plasma table diy cnc plasma cutter machine price:

1.Heavy machine bed after high temperature treatment can keep running speed and cutting precison.

2.USA Hypertherm and Chinese Huayuan plasma source have good cutting quality and long lifetime.

3.FastCAM or StarCam software with nesting function can save material easily,also convenient to read and process.

4.If cut thick metal,cutting head will have cooling system,which can quickly cool surface of material to avoid burr and smoke.

5.Stepper motor with high precision rack and pinion, to ensure the cnc plasma Machine has small noise,smooth, precise coordinates of the mobile performance.

2.USA Hypertherm and Chinese Huayuan plasma source have good cutting quality and long lifetime.

3.FastCAM or StarCam software with nesting function can save material easily,also convenient to read and process.

4.If cut thick metal,cutting head will have cooling system,which can quickly cool surface of material to avoid burr and smoke.

5.Stepper motor with high precision rack and pinion, to ensure the cnc plasma Machine has small noise,smooth, precise coordinates of the mobile performance.

Working area for your choose:

---------Working area :1200*1200mm/ 1300*2500mm / 1500*3000mm /2000*3000mm/ 2000*4000mm

Power supplier for your choose:

--------- power supplier:45A/65A/85A/105A/125A/200A

Factory price 5 x 10 plasma table diy cnc plasma cutter machine price:

|

Name |

Specification |

|

Working Area(X*Y) |

1300×2500mm |

|

Machine Structure |

Welded |

|

X Y Guide Rail |

Square Rail |

|

X Y Transmission |

Imported Rack gears |

|

X\Y\Z Axis Driver |

Stepper Motor |

|

Control System |

Starfire |

|

Working Dictate |

G Code |

|

Cutting thickness |

0.5-20mm |

|

Plasma Generator |

60/100/120/160A Power Generator |

|

Cutting Speed |

0-8000mm/min |

|

Document Transmission Form |

USB Interface |

|

Working Form |

Untouched Arc Striking |

|

Working Voltage |

3-Phase 380V |

|

G.W. |

980KGS |

|

Packing Size |

12CBM |

Main Features of Factory price 5 x 10 plasma table diy cnc plasma cutter machine price:

1. Beam with light structural design, the structure has good rigidity, light weight, exercise inertia and low cost.

2. Gantry-type structure, Y-axis synchronous dual-motor drive and XYZ axis with circular rail (optional formula-type linear guide), steady transmission, and high accuracy.

3. For advertising solid light, groove metal panel and bottom plate of the word for cutting, cutting accuracy good indicator. If equipped with the U.S. Treasure plasma power can achieve lower laser cutting machine.

4. And other advertising devices(vacuum forming machines, gear cutting machine) to form ad word processing pipeline, completely solve the traditional way of manual processing. Improve efficiency several times.

5. Cutting speed, high accuracy and low cost.

6. CNC system configuration high, automatic arc, stable performance, the success rate of 99% arc.

7. Support Wentai, Beihang Haier, ARTCAM, Type3 software such as the standard G code path generated file can also be read by software conversion software such ad AUTOCAD generated DXF formats. U disk exchange control system processing files, easy to operate.

8. Plasma torch power supply and supporting all famous brands, a number of national patents by the manufacturers.

Heavy duty structure

Heavy duty structure, keep machine working stable.

Exhaust fans and water tank table for optional.

Heavy duty structure, keep machine working stable.

Exhaust fans and water tank table for optional.

Starfire control system+THC

Control system Brand: Original Starfire

Language: English

Automatically adjust the height of the torch according to the material fluctuation, realize the climbing and cutting, and apply to

various uneven materials..

China LGK Plasma source

Brand: LGKOriginal: CHINA

Power: 40A/63A/100A/120A/160A/200A

Power: 40A/63A/100A/120A/160A/200A

Hypertherm / Powermax plasma source

Brand: Hypertherm / powermaxOriginal: USA

Power: 45A/65A/85A/105A/125A/200A

Power: 45A/65A/85A/105A/125A/200A

Product Application of 1325 1530 tables cnc plasma cutter cutting machine for sheet metal:

plasma cutting machine applications industry:

Ship Building, Construction Equipment, Transport Equipment, Aerospace Industry, Bridge Building, military industrial, wind power, Structural Steel, Boiler containers, Agriculture Machinery, Chassis electrical cabinets, Elevator manufacturers, Textile Machinery, Environmental protection equipment,etc

plasma cutting machine applications Materials:

All kinds of metal materials such as steel, copper, aluminum and stainless steel can be processed. Applies to iron plate, aluminum plate, galvanized sheet, White Steel plate, Titanium plates, and so on like the sheet metal.

|

Software CD, English manual and training video is available. 1. One year guarantee for the whole set of machines, not including normal replacement of wearing parts. 2. 24 hours technical support by email or calling. When it is necessary, we will send technician to the customer side to solve the problem. 3. User-friendly English manual and CD for machine using and maintaining. 4. Free lifetime upgrading of self-developed English software. |

plasma cut machine

Jinan GoodCut CNC

Jinan GoodCut CNC Machinery Co.,Ltd.

GoodCut has Purchasing department, The design department, The production department, Quality inspection department, packaging and transportation department, The sales department, After sales service department.

We can offer highest quality machine, and competitive price.

Mainly manufacture and sale cnc router, laser engraving, marking, cutting machine,

wood lathe machine, fiber cutting machine, plasma cutting machine, 3D scanner etc.

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

Good Quality

1. 15 engineers with more than 10 years rich working experience, manufacture high precision machines;

2. Three-day 72-hour testing machine inspection, after confirming that the machine has no quality problems, then it will be shipped;

3. 4 QC staffs do strict evaluations on in-coming inspections, in-process inspections and final inspections.

Good Price

1. GoodCut manufactures about 50 sets of machines per month, with a large sales volume. We have long-term cooperation with parts suppliers, can get advantageous prices of parts, so that the price of machine is very competitive;

2. GoodCut aims to develop long-term cooperation with new and regular customers, and to give customers the best prices with the most sincere attitude.

Good Service

1. English manual and video for machine using and maintaining, explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching to eliminate customer worries.

Hot Searches