NaN / 0

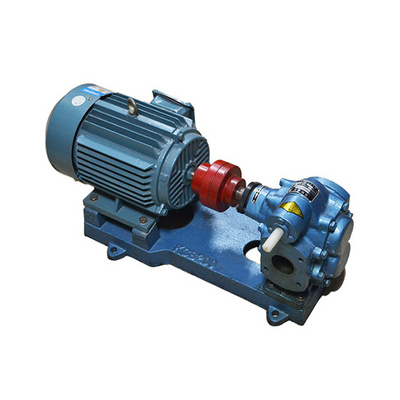

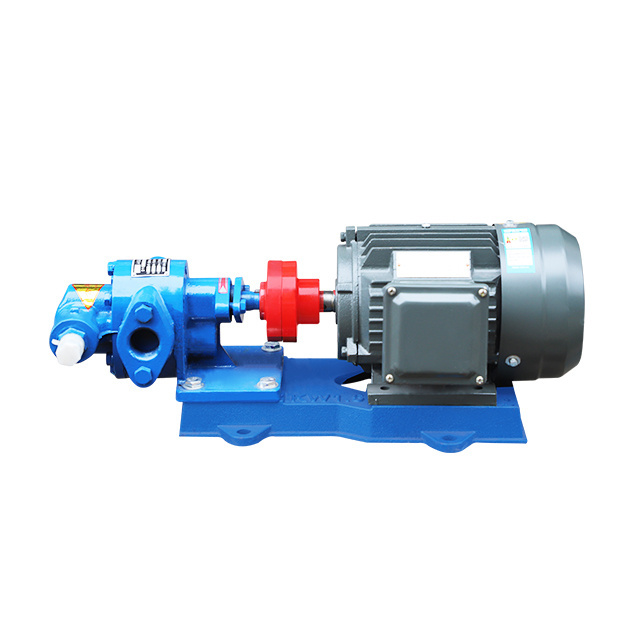

Diesel lube fuel oil petroleum electric oil transfer gear pump

Get Latest Price

US$ 137

≥1 Sets

Quick Details

Application:

Other, Biofuel Industry, Industrial Utilities

Pressure:

3.3bar

Voltage:

380V

Warranty:

1 year

Product Details

1、 KCB gear oil pump product overview:

It is suitable for conveying lubricating oil with no solid particles and fibers, no corrosion, temperature not higher than 80 ° C, viscosity of 5 * 10-6 ~ 1.5 * 10-3m2 / S (5 ~ 1500cSt) or other liquids similar to lubricating oil.

2、 KCB gear oil pump model meaning:

3、 Features of KCB gear oil pump:

1. The gear oil pump is mainly composed of gear, shaft, pump body, safety valve, shaft end seal and other parts. The gear has high hardness and strength after heat treatment, and is installed in the replaceable shaft sleeve together with the shaft. The lubrication of the parts in the pump is achieved automatically by using the conveying medium when the pump is working.

2. There are reasonable oil drain and oil return grooves in the pump, which make the gear bear less torque force in working, so the bearing load is small, the wear is small, and the pump efficiency is high.

3. The pump is equipped with a safety valve as overload protection. The total return pressure of the safety valve is 1.5 times of the rated discharge pressure of the pump. It can also be adjusted according to actual needs within the allowable discharge pressure range. However, it should be noted that the safety valve can not be used for long-term operation of the pressure reducing valve, and can be separately installed on the pipeline when necessary. From the view of the extended end of the spindle to the pump, it rotates clockwise.

4、 KCB gear oil pump is mainly used for:

1. It can be used as transmission and booster pump in oil transportation system

2. In the fuel system, it can be used as a fuel pump for transmission and pressurization

|

Fault phenomenon

|

Possible causes

|

Exclusion method

|

|

|

a. Suction height exceeds rated value

b. Air leakage in suction pipe

c. Wrong direction of rotation

d. Suction pipe blocked or valve closed

e. The safety valve is stuck or damaged

f. Liquid temperature is low and viscosity is increased

|

a. Increase suction level

b. Check the joints and seal them with sealing materials

c. Correct the direction indicated by the pump

d. Check whether the pipe is blocked and the valve is open

e. Remove the safety valve, clean and grind the valve hole with fine

sand, and use it to match

f. Preheat liquid or reduce discharge pressure

|

|

|

a. Wear of sealing ring

b. Packing wear

c. Mechanical seal wear or scratch and other defects

d. Mechanical seal spring failure

|

a. Replace the sealing ring

b. Adjust the tightness of packing gland and replace or supplement packing

c. Replace or regrind

d.Replacement

|

|

|

b. The liquid level of suction pipe is shallow

c. Air entering the pipe

d. The discharge pipe resistance is too high

e. Serious wear of gear bearing or side plate

f. The viscosity of the inhaled liquid is too high

g.Suction height exceeds rated value

|

a. Eliminating dirt on the filter screen of gear oil pump

b. The suction pipe extends below the liquid level

c. Check the connections and make them sealed

d. Check whether the discharge pipe and valve are blocked

e. Remove, clean and repair defects or

replace

f. Heating, viscosity reduction or treatment

g. Reduce the height of oil absorption and shorten the length of oil suction

pipe |

Hot Searches