NaN / 0

Fisher Original 299H pressure reducing regulator valve for burner industrial area

Get Latest Price

US$ 1277

≥1 Pieces

US$ 1200

≥10 Pieces

US$ 1191

≥20 Pieces

Quick Details

Type:

Gas Burner accessory

Weight (KG):

10

Place of Origin:

America

Brand Name:

Fisher

Product Details

Product Description

Fisher Original 299H pressure reducing regulator valve for burner industrial area

Title goes here.

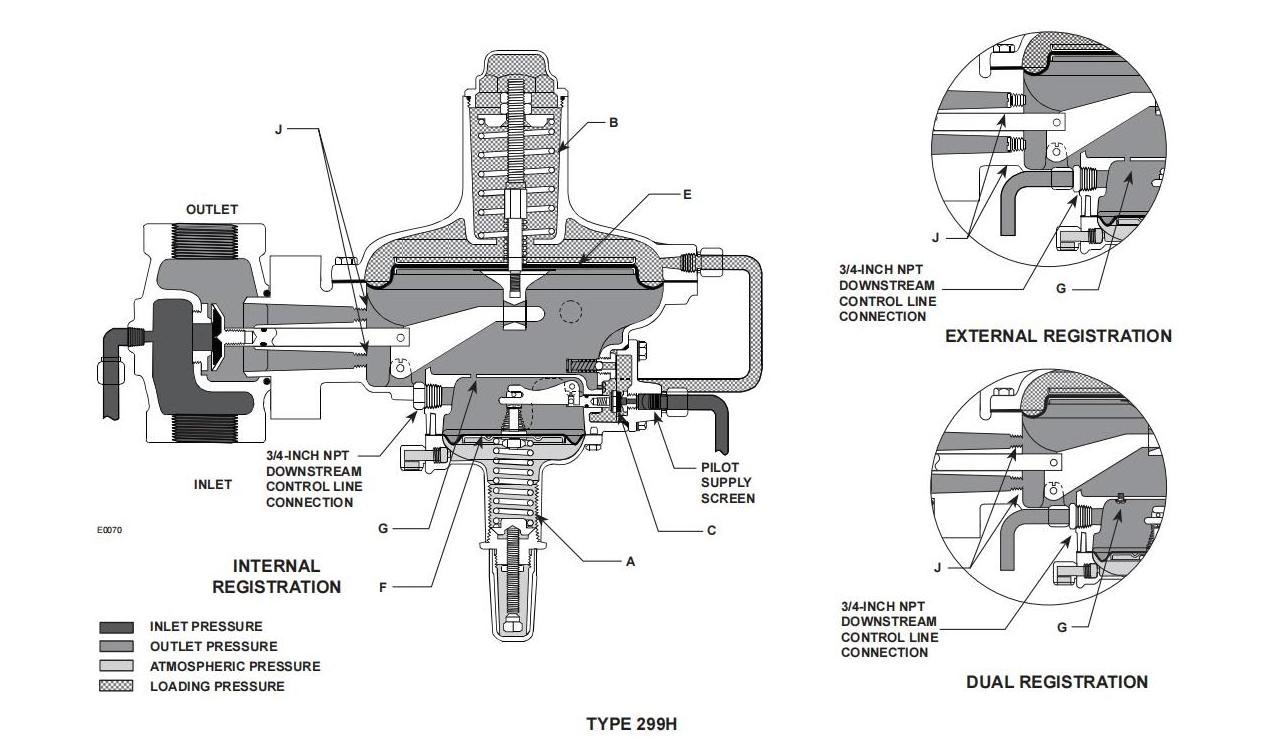

299H Model Pressure Reducing Regulators LPG Regulator

Specifications for 299H Series constructions are given below. Some specifications for a given regulator as it originally comes from the factory are stamped on a nameplate located on the actuator upper casing.

Specifications

Specifications for 299H Series constructions are given below. Some specifications for a given regulator as it originally comes from the factory are stamped on a nameplate located on the actuator upper casing.

Specifications

Available Constructions

Type 299H: Pilot-operated pressure reducing regulator with a pilot integrally mounted to the actuator casing.

Body Sizes and End Connection Style

2-inch FNPT

Maximum Operating Inlet Pressure by Orifice Size

1/4 x 3/8 inch / 6.4 x 9.5 mm . . . . 175 psig / 12.1 bar

3/8 inch / 9.5 mm . . . . . . . . . . . . . . 175 psig / 12.1 bar

1/2 inch / 13 mm . . . . . . . . . . . . . . 175 psig / 12.1 bar

3/4 inch / 19 mm . . . . . . . . . . . . . . 150 psig / 10.3 bar

7/8 inch / 22 mm(5) . . . . . . . . . . . . 125 psig / 8.6 bar

1 inch / 25 mm(5) . . . . . . . . .. . . . . . . 100 psig / 6.9 bar

1-3/16 inch / 30 mm(5) . . . . . . . . . . . . . 80 psig / 5.5 bar

Maximum Casing and Emergency Outlet Pressure

66 psig / 4.5 bar

Pressure Control Accuracy (Fixed Factor) (PFM)

±1%(3) of absolute control pressure

Minimum Differential Pressure For Full Stroke

1.5 psid / 0.10 bar

Construction Materials

Actuator Upper Casings: Aluminum

Actuator Lower Casing: Aluminum

Pilot Spring Case: Aluminum

Actuator Diaphragm: Nitrile (NBR)

Pilot Diaphragm: Nitrile (NBR)

Pilot Inlet Screen: Stainless steel

Valve Body: Cast iron, Ductile iron, or Steel

Orifice and Valve Stem: Aluminum

Disk Holder: Aluminum holder with

Nitrile (NBR) disk

Main Disk Construction: Nitrile (NBR)

Metal Trim Parts For Pilot: Aluminum

Pilot Disk Construction: Nitrile (NBR)

O-Rings: Nitrile (NBR)

Fittings: Steel (standard) or Stainless steel

Tubing: Stainless steel

Features

• Compact in Size—Small envelope because of the built-in pilot and internal registration.

• Unique No Bleed Monitor System—Flexible worker/monitor system setup that allows for bleed to be piped to the intermediate piping thus eliminating downstream bleed which reduces lost and unaccounted for gas. Another advantage of this configuration is that the system lockup pressure is that of the worker instead of the monitor.

• Not an Adaptation of Existing Regulators—New design of integrated cases and internal registration ports.

• Wide Variety of Applications—Natural gas distribution systems, gas supply to industrial boilers, furnaces, ovens, mixers, plant air service.

• Highest Quality— Designed and manufactured to ISO 9001 standards.

• Accuracy—Keeps constant inlet pressures to downstream equipment by accurately controlling distribution system pressures at widely varying flow rates and supply pressures for maximum efficiency and best operation, or by eliminating the need for pressure-compensating meters by holding a steady pressure to the meter inlet.

• Optional Token Relief—The Types 299HR and 299HSR with an integral token relief in the pilot is designed to relieve minor

overpressure caused by thermal expansion.

• High-Capacity Pressure Control—Actuator diaphragm responds quickly to downstream 1pressure change, causing immediate correction in main valve position. Pilot responds simultaneously and controls final positioning of main valve. This action permits full main valve travel, resulting in higher capacity than could be obtained without an external pilot regulator.

• Easy Registration Conversion—Two screws and O-rings change internal registration to external or dual registration.

• Easy Startup—No special procedure required.

Type 299H: Pilot-operated pressure reducing regulator with a pilot integrally mounted to the actuator casing.

Body Sizes and End Connection Style

2-inch FNPT

Maximum Operating Inlet Pressure by Orifice Size

1/4 x 3/8 inch / 6.4 x 9.5 mm . . . . 175 psig / 12.1 bar

3/8 inch / 9.5 mm . . . . . . . . . . . . . . 175 psig / 12.1 bar

1/2 inch / 13 mm . . . . . . . . . . . . . . 175 psig / 12.1 bar

3/4 inch / 19 mm . . . . . . . . . . . . . . 150 psig / 10.3 bar

7/8 inch / 22 mm(5) . . . . . . . . . . . . 125 psig / 8.6 bar

1 inch / 25 mm(5) . . . . . . . . .. . . . . . . 100 psig / 6.9 bar

1-3/16 inch / 30 mm(5) . . . . . . . . . . . . . 80 psig / 5.5 bar

Maximum Casing and Emergency Outlet Pressure

66 psig / 4.5 bar

Pressure Control Accuracy (Fixed Factor) (PFM)

±1%(3) of absolute control pressure

Minimum Differential Pressure For Full Stroke

1.5 psid / 0.10 bar

Construction Materials

Actuator Upper Casings: Aluminum

Actuator Lower Casing: Aluminum

Pilot Spring Case: Aluminum

Actuator Diaphragm: Nitrile (NBR)

Pilot Diaphragm: Nitrile (NBR)

Pilot Inlet Screen: Stainless steel

Valve Body: Cast iron, Ductile iron, or Steel

Orifice and Valve Stem: Aluminum

Disk Holder: Aluminum holder with

Nitrile (NBR) disk

Main Disk Construction: Nitrile (NBR)

Metal Trim Parts For Pilot: Aluminum

Pilot Disk Construction: Nitrile (NBR)

O-Rings: Nitrile (NBR)

Fittings: Steel (standard) or Stainless steel

Tubing: Stainless steel

Features

• Compact in Size—Small envelope because of the built-in pilot and internal registration.

• Unique No Bleed Monitor System—Flexible worker/monitor system setup that allows for bleed to be piped to the intermediate piping thus eliminating downstream bleed which reduces lost and unaccounted for gas. Another advantage of this configuration is that the system lockup pressure is that of the worker instead of the monitor.

• Not an Adaptation of Existing Regulators—New design of integrated cases and internal registration ports.

• Wide Variety of Applications—Natural gas distribution systems, gas supply to industrial boilers, furnaces, ovens, mixers, plant air service.

• Highest Quality— Designed and manufactured to ISO 9001 standards.

• Accuracy—Keeps constant inlet pressures to downstream equipment by accurately controlling distribution system pressures at widely varying flow rates and supply pressures for maximum efficiency and best operation, or by eliminating the need for pressure-compensating meters by holding a steady pressure to the meter inlet.

• Optional Token Relief—The Types 299HR and 299HSR with an integral token relief in the pilot is designed to relieve minor

overpressure caused by thermal expansion.

• High-Capacity Pressure Control—Actuator diaphragm responds quickly to downstream 1pressure change, causing immediate correction in main valve position. Pilot responds simultaneously and controls final positioning of main valve. This action permits full main valve travel, resulting in higher capacity than could be obtained without an external pilot regulator.

• Easy Registration Conversion—Two screws and O-rings change internal registration to external or dual registration.

• Easy Startup—No special procedure required.

Specification

|

Brand

|

Fisher

|

|

Model

|

299H

|

|

Brand

|

Fisher

|

|

Environment Temperature

|

Normal

|

|

Deliver time

|

2-30days

|

|

Term of payment

|

EXW/FOB

|

|

Usage

|

Gas Burner Parts

|

|

After Warranty Service

|

Video technical support

|

Recommend Products

About Us