NaN / 0

Popular 2 piece forged new designs concave alloy wheels rims

Get Latest Price

US$ 480

≥4 Pieces

US$ 460

≥12 Pieces

Quick Details

Finishing:

Silver/Hyper silver/Black/Matt black/Red/Polish etc

Width:

7.5 to 12 inch

Place of Origin:

Jiangsu, China

Brand Name:

SS RACING

Product Details

Images

|

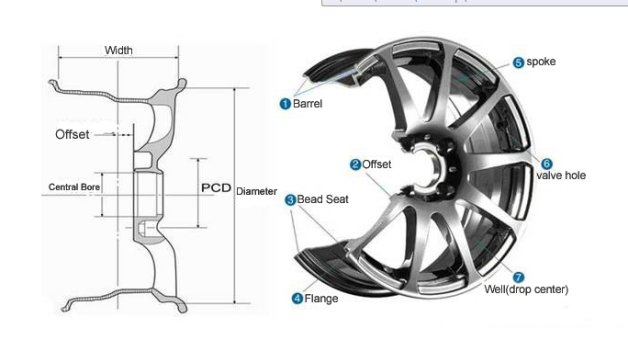

Size

|

20" 22"

|

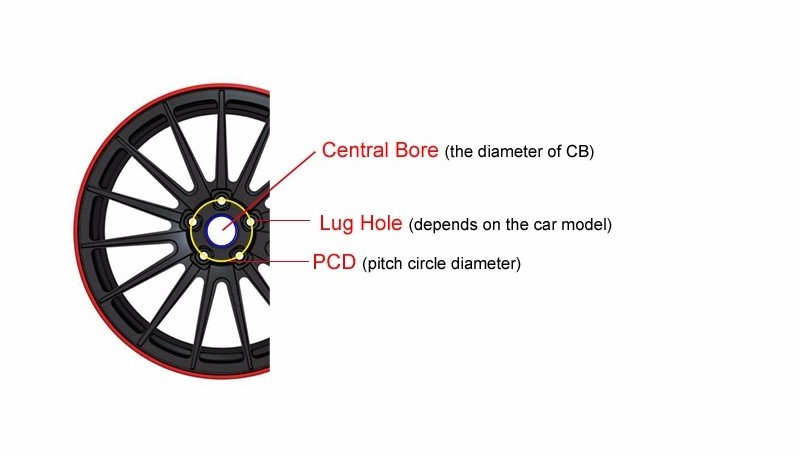

H/PCD

|

5x120

|

|

ET

|

+35

|

CB

|

57.1-74.1

|

|

Material

|

A6061

|

Weight(NW/GW)

|

15kg/16kg

|

|

Color/Finish

|

Bronze and Black

|

Load Rating

|

690kg/1380lbs

|

Product Description

·

Model No. SC517

·Material: A6061 T6

·Load Rating: we make based on VIA/JWL standard

·Function: For luxury car

Features

Light

light weight, fuel saving compared to casting rims, and only slight deformation after impact, even if the puncture can share the weight of the car, it will not cause rollover.

Safe

high rigidity, The forged wheel is much safer than the casting wheel. Since the casting wheel is cooled by the molten liquid metal filling cavity, it is easy to produce air holes in the manufacturing process; and the forged wheel is mainly extruded at a high temperature to soften the aluminum block. The method of molding. Therefore, the molecular density and the molecular spacing are smaller than those of the casting wheels, so the wheel rigidity is greatly improved. Moreover, because the forging process makes the molecular structure very tight, it can withstand higher pressures, so the forged wheels are lighter and use less material than the cast wheels at the same strength and strength.

Refresh the website, you can see the flash!

Side Cutting shows, material in Forged wheel is much denser and evenly distributed.

(left forged right cast) It means

stronger and more comfortable during driving!

Forged Granite Structure

Denser and more evenly distributed

Cast Granite Structureunder microsco

Perfect Look

Due to the high strength of the forged wheel, it is possible to select a more compact and slim shape.

Tuning Forged Wheel

OEM Original Wheel

Based on Standards

We are an alloy wheel manufacturer and all our wheels passed VIA/JWL, SAE J2530 or TUV based on the request of customers. We are supplying wheels (both aftermarket designs and OEM replica designs) mainly to USA and Europe.

High Quality

100% of our OEM products are inspected by X-ray machine.

Use a continuous heat treatment furnace for T6 treatment.

A package designing, production and service

For some start-up companies, we can help build the brand. We have 17 years of well production background and experience in quality control and service.

Our R&D team has more than 17 years experience in Designing and Engineering!

We make 2D strength analysis for you

We make 3D drawing for your confirmation

We make FEA strength analysis for you

Why choos us

Certificates

Care & Warranty

Warranty: Structure -- lifetime

Painting -- 24 months

Chrome -- 12 months

FAQ

Q1. Are you factory or trading company?

A:We are a professional alloy wheel factory.

Q2. How can I get your price list?

A: Please send an inquiry to us and tell us what you need and quantity, our sales will reply you within 12 hours with a price list.

Q3. Can I get a sample to check quality before mass order?

A: Yes, you can. Welcome to place sample order to check our quality. I do believe our high quality products will bring more orders for you from your clients!

Q4. Any warranty for your products?

A: Our warranty is based on US market standard.

Structure: warranty - lifetime

Painting: warranty - 24 months

Other warranty can be as per customer's requirements.

Q5. Any certifications for your products?

A: Our alloy wheels can pass VIA/JWL, ISO/TS 16949, QS 9001.

Q6. How about the delivery time?

A: If we have inventory, lead time will be 1-3 days

If we need to produce, lead time will be 25-45 days

Q7. Do you support OEM/ODM service?

A: Yes, we do support, we have experienced R&D team, so welcome to place OEM/ODM orders to us.

Q8: At last, about the payment terms, any convenient and safe way for our buyers?

A:You can pay by T/T, L/C, Ali pay or PayPal ect.