NaN / 0

1260 ceramic fiber blanket high temperature kiln insulation blankets refractory ceramic fiber wool for furnace

Get Latest Price

US$ 0.5

≥20 Rolls

Quick Details

Thickness:

10-50mm, 10-50mm

Width:

610/1220mm, 610/1220mm

Chemical Composition:

AL2O3+SIO2, Al2O3,Sio2

Ultimate Strength (≥ MPa):

0.04, 0.04

Product Details

1260 ceramic fiber blanket high temperature kiln insulation blankets refractory ceramic fiber wool for furnace

Product Description

Ceramic Fiber Blanket Introduce

Ceramic Fiber Blanket is composed of long flexible, interwoven fibers manufactured by the “spun” process yielding a strong,lightweight, durable product. This material can be used for applications with temperatures from 1000°F (538°C) to 2600°F (1425°C).

Ceramic Fiber Blanket have high tensile strength for longer life and durability. Maxwool Ceramic Fiber Blankets contain no binders and are completely inorganic. Thermal and physical properties are retained after drying following wetting by oil, steam or water. This ceramic fiber blanket products are completely inorganic, so there are no fumes when heating for the first time.

Advantages

Ceramic Fiber Blanket Features

High temperature and fire resistance

Excellent thermal stability and chemical stability

Great elasticity and thermal shock resistance

Low heat conductivity and heat capacity

Good sound absorption property

Application

Ceramic Fiber Blanket Application

Ceramic Fiber Blankets can be used in various applications which include Petrochemical, Refining, Steel, Ceramic, Glass, Fire Protection and Power Generation. This product can be fabricated and shop installed for most applications.

Wall and backing lining insulation of Industrial kiln and heating device

High heat equipment insulation

High temperature pipeline insulation

High temperature kiln door gasket

Fire insulation for electrical apparatus element

As raw materials for refractory modules and collapse block

Fire insulation for Military equipment

High heat insulation for aerospace, steel and petrochemical industry

Specification

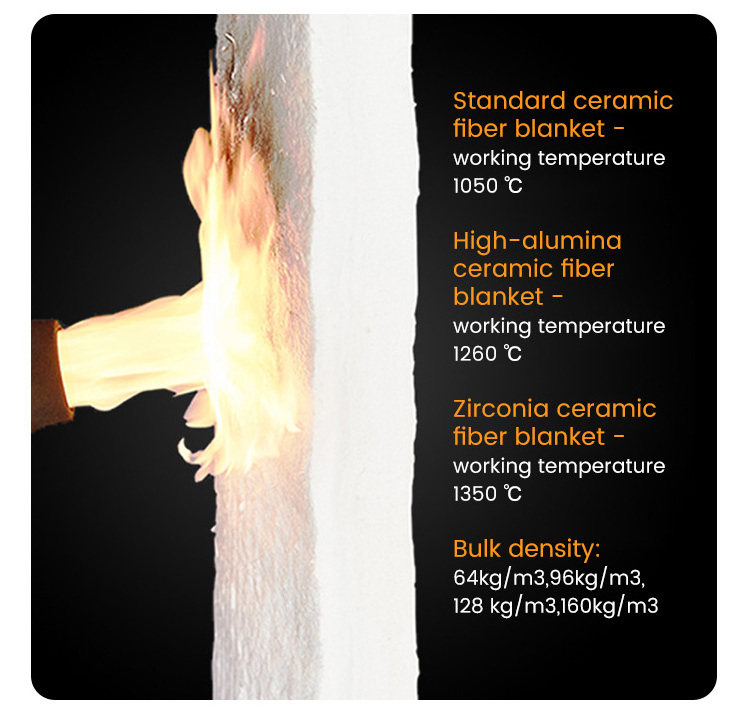

Ceramic Fiber Blanket

Phsyical and chemical index:

| Type | 1260 Blanket | 1400 Blanket | 1500 Blanket | 1600 Blanket |

| Classification temperature ( °C) | 1260 | 1425 | 1500 | 1600 |

| Melting point (°C) | 1760 | 1700 | 1760 | - |

| Colour | White | White | Blue gree | White |

| Fiber diameter ( u m) | 2.6 | 2.8 | 2.65 | 3.1 |

| Fiber length (mm) | ~250 | ~250 | ~150 | ~100 |

| Linear shrinkage(%) | (1100oC x 24 hrs)1.8 | (1300 o C x 24 hrs) 1.5 | - | - |

| Shot content (>212 micro meter) (%) | 18 | 18 | - | - |

| Thermal conductivity Kcal/mh °C (W/mK) ,ASTM C201 | ||||

| 1260 blanket | 64 kg/m3 | 96 kg/m3 | 128 kg/m3 | 160kg/m3 |

| mean 400°C | 0.13 | 0.12 | 0.07 | 0.09 |

| mean 600 °C | 0.21 | 0.17 | 0.12 | 0.14 |

| mean 800°C | 0.30 | 0.25 | 0.16 | 0.20 |

| 1400 blanket | - | - | 128 kg/m3 | 160kg/m3 |

| mean 600 °C | - | - | 0.13 | 0.14 |

| mean 800 °C | - | - | 0.20 | 0.20 |

| mean1000 °C | - | - | 0.29 | 0.28 |

| Chemical composition (%) | ||||

| Al2O3 | 47.1 | 35.0 | 40.0 | 72 |

| SiO2 | 52.3 | 49.7 | 58.1 | 28 |

| ZrO2 | - | 15.0 | - | - |

| Cr2O3 | - | - | 1.8 | - |

| Bulk density(Kg/m3) | 64,96,128,160 | |||

| Available size(mm/roll) | 7200*600*6,12.5,20,25,38;3600*600*50 | |||

Packaging & Shipping

Hot Searches