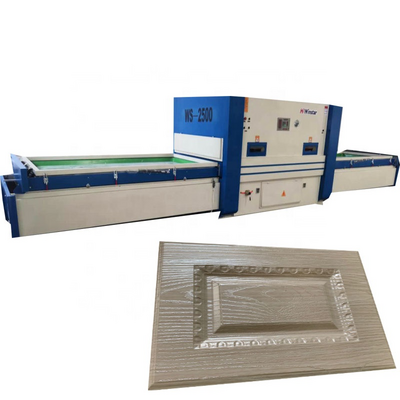

Feature:

1.Net weight :BFM-2600 Whole machine net weight meet 900KGS, Other supplier same machine about 600KGS .The overall stability of

the equipment is enhanced after the weight of the equipment increases.

2.Insulating layer:Adopt special thickened 40mm insulation layer , Other supplier use 20mm-30mm During heating the thickening of

insulation layer improves the insulation effect and saves resources.

3.More safety opening device:Use SC80*300 double cylinder,which can meet 500KG opening force, the connecting lever thickness meet

20mm .more safety . For other supplier connecting lever only about 10mm .

4.Install vacuum storage tank:Our machine is automatic film laminating machine ,when the vacuum storage tank pressure is

insufficient,the vacuum pump will working automatically ,this way also extend the service life of vacuum pump . But for other

supplier usually is manual and without vacuum storage tank

5.PVC film thickness :Until now we tested the max. membrane press film thickness meet 0.5mm

6.Easy movement :Install four wheels on the machine bottom, easy movement .

7.Two inspection window: This way it is more easy to check the inside working condition .but for other supplier only have one

inspection window

8.Install the retainer frame ,more convenient for use .

Data Sheet