NaN / 0

450mm butt fusion electrofusion gas pipe welding machine welding electrofusion for hdpe pipe fittings

Get Latest Price

US$ 610

≥1 Pieces

US$ 585

≥2 Pieces

US$ 575

≥3 Pieces

Quick Details

Place of Origin:

Shandong, China

Brand Name:

CNBADA

Voltage:

220V

Frequency:

50HZ

Product Details

BDDR-315V ELECTROFUSION WELDING MACHIN

Our advantage:

1) CE, SGS, ISO9001 certificate

2) Provide on line video technique teaching of fusion welding

3) 2 years warranty

4) Provide customized welding machine

Brief introduction of BDDR-315V ELECTROFUSION WELDING MACHIN

1) Suitable for welding of plastic pipes and fittings made from PE, PP & PVDF

2) Easy to use

3) Welding position can transform that it is convenient for welding all kinds of pipe fittings

|

Model |

PE Electrofusion Welding Machine |

|

Equipment Model |

BDDR-315V |

|

Welding Range (PE Solid Wall) |

20mm-315mm |

|

Operating Voltage |

175-240V 50HZ AC |

|

Constant Voltage/Output Voltage |

Valid Values 10V~ 60V |

|

Constant Current/Output Current |

Valid Values 5A~ 60A |

|

Maximum Output Power |

3.0KW |

|

Ambient Temperature |

-10~ +40 ℃ |

|

Time Accuracy |

0.1% |

|

Output Voltage Accuracy |

1% |

|

Storage Records |

6×500 records |

|

Net Weight |

21.7KG |

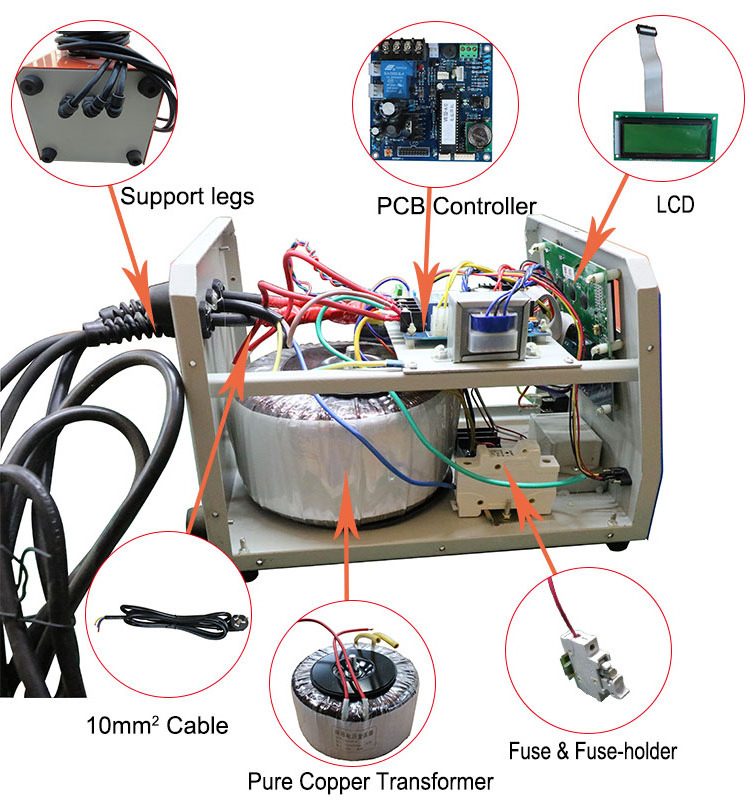

1. Add support legs to prevent moisture, dust and shock absorption .

2. High precision PCB Control ler , pure copper transformer, 10mm 2 cable, Fuse & Fuse-holder, safer operation .

3. Scraper, spare copper connector, scanner and other optional accessories are complete .

Our advantage:

1. High - level MCU is used as control core, with abundant parameter setting, measuring and perfect protective function.

2. Wide power supply and voltage input, suitable for filed electrical network level.

3. High precision control of electrial stability and time, insuring welding quality.

4. Swift output response time when power supply breaks, high satbility.

5. Many programmable welding functions, suitable for welding requirment for various fittings.

6. Flexible welding parameter input mode; manual input through keyboard or bar cod scanning input.

7. Smart Gas, Colud welding is available.

Jinan Bada plastic pipe welding equipment Co., Ltd. is a 13 years professional top manufacturer with CE, SGS, ISO9001 certificate. The company participated in the drafting of GB and cooperated with well-known universities to train welding technology talents. The company has a large number of spare parts inventory, and can customize welding machines with different standards such as American Standard, British standard and German standard, so as to meet the needs of all customers.

Our products including: Hydraulic Butt Fusion Machines, Manual Butt Fusion Machines, Electrofusion Welding Machines, Socket Fusion Welding Machines, Workshop Fitting Welding Machines, HDPE Fittings, Electrofusion Fittings, etc.

WHY US

1) Advanced laboratory

2) Mature fusion welding technology

3) Spare parts warehousing quality inspection, inspection during the production process, complete machine inspection and commissioning before delivery.

4) Cooperate with well-known universities, participate in the drafting of GB national standard, provide training for fusion welding technicians at home and abroad, and support free online video guidance.

5) Sufficient spare parts inventory, short delivery time, less than 50 sets, delivery time 7-10 working days, in line with ROHS 2.0 standard.

Related products

Hot Searches