NaN / 0

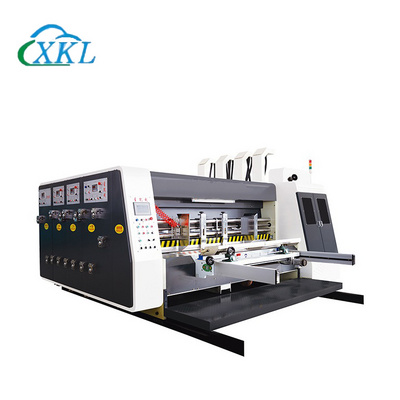

Automatic flexo carton box making machine offset printing slotting die cutting machine

Get Latest Price

US$ 19700

≥1 Sets

Quick Details

Brand Name:

XKL

Marketing Type:

New Product 2024

Type:

automatic, carton printing slotting die cutting machine

Weight (KG):

5000 KG

Product Details

Hot Searches