NaN / 0

Polystyrene Sandwich Panel Walls Maker Insulation EPS Foamed Concrete Board Mold Cement Slab Production Machine

Get Latest Price

US$ 15000

≥1 Sets

Quick Details

Application:

Construction machinery

Production Capacity:

Customized

Place of Origin:

Guangxi, China

Brand Name:

HONGFA

Product Details

Product Description

- WELCOME TO HONGFA MACHINERY -

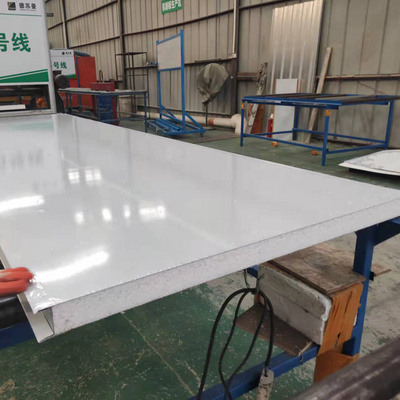

Automatic Cement EPS Polystyrene Sandwich Panel Maker

for partition wall construction

(A) Raw Materials:

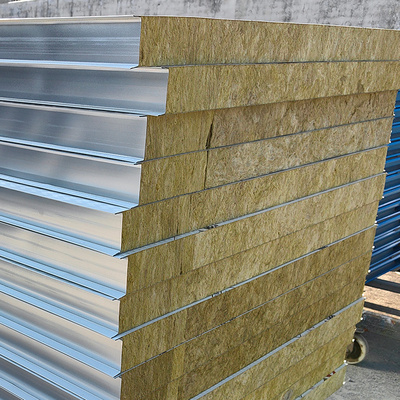

1. Good thermal isolation EPS bonding mortar as core material.

2. Calcium silicate board as the surface cover material.

3. Properly mixed with sand / fly ash, slag and additives .

Note: The 2 cover boards of the new type composite sandwich board are composed of high strength water resistant, calcium silicate board with good waterproof properties.

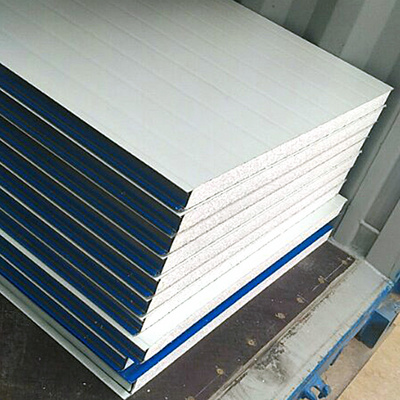

(B) EPS Sandwich Panels Size & Type (Flexible) :

|

Size: Width 610mm Length 2440mm (2270/3000mm, or customized)

Thickness: 60 - 25 0mm (size and thickness can be adjusted).

Type: Hollow / Solid / T Shape / L Shape |

|

- High, multistory building as non-bearing wall, also can be sound insulation, fire partition wall.

- This product's application is a new breakthrough of the world's wall materials reform, this wall panel have tested by the relevant institutions and its strength, sound insulation, fire resistant, radioactive, water resistance and other performance indexes all reach or over the relevant national standards.

(C) Cement EPS Sandwich Panel Advantages:

|

Why invest an EPS cement wall panel production line?

Advantage s of Project

( 1 ) Low Cost & High Profit

The main raw materials of this light wall panel are industrial residue fly ash, slag, ceramic, portland cement and EPS foam particles, the production process is simple and low cost.

( 2 ) Advanced Technology

( 3 ) Fully Meet ing Requirements of Building Function

The overall world development trend of brick from clay to non-clay, from solid to hollow, from the small to large, from the heavy to light, from low intensity to high-strength, high to low energy consumption, a single function to multi-wall development. And the project is stressed to wall lightweight, high strength, thermal insulation, waste utilization, energy conservation and other functions. Therefore, the implementation of the project is imperative.

( 4 ) Low Business Risk

(A) Long-term stability advantages: Due to the limit of functional requirements of the restrictions and sources of raw materials needed to be broad and rich, but also by limiting the requirements of the human environment, the wall construction material development developers is relatively difficult.Once this kind of wall material is successfully developed and is recognized by the government and society, its competitive advantage will be relatively stable and long-term business in the market.

(B) Mechanization in production, less workers but high output and stability.

(C) It is a comprehensive utilization of the industrial wastes project, and will get a great support by the State.

Plant Wall Panel I nfrastructure Requirements

Water: to produce 60m2 panel(9 cm thickness as example) required one ton of water. No special requirements for water quality, clean water can be used for production.

Electricity: installed power 100 kw (depends on the capacity).

Air and steam : Air compress or and boiler.

Land: 1200-2000m2 workshop and 9 meters high (depending on the capacity).

Labor: 6 workers in total ( take capacity 100,000/yearly as example).

Production Flow Chart

Panel Production Line Layout

Production line is divided into 6 sections:

(1) Material Storage and Weighing System

(2) Panel Molding System

(3) EPS Expanded System

(4) Mixing System

(5) Mobile Slurry Grouting System

(6) Mobile De-Moulding & Turnover System

- We have some types of sandwich panel moulding machine, for different investment.

Packaging & Shipping

Full containers.

Industrial Equipment Packing.

Electrical components are packed in wooder cases with waterproof.

Our Services

Free Inquiry and Consultation

- Free inquiry and consulting support on analyzing customers' needs and market prospect.

- Free Solution to Set up a Factory.

- Provide perfect solution to set up a factory to perform EPS sandwich cement wall panel machine operation.

From the day our products sold, we will promise to do as follows:

(1) Provide corresponding technical solutions and site layout;

(2) Provide guidance equipment installation and operation for users.

(3) For each equipment, we will train mainly operating personnel 5-10.

(4) 12 months guarantee, and provide lifelong technical support.

Hot Searches