NaN / 0

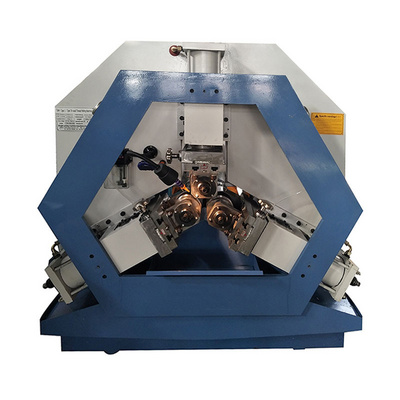

Automatic Steel Bar Thread Rolling Machine Rebar Thread Roller/Screw Making Machine

Get Latest Price

US$ 4000

≥1 Pieces

Quick Details

Place of Origin:

Henan, China

Power:

5500

Dimension(L*W*H):

1600*1550*1445mm

Weight:

1700

Product Details

Automatic Steel Bar Thread Rolling Machine Rebar Thread Roller/Screw Making Machine

Product Description

this model is mainly used for processing precision standard parts of external thread and high strength, including regular thread, trapezoid thread and modulus thread.

The objective material to be processed including carbon steel, alloy steel and nonferrous metal with elongation over 10% and tensile strength less than 100kgf/mm2.

Structure of steel bar thread knurling machine :

1.Machine tool:steel welding

2.Rolling wheel:hard alloy

3.motor:380V/3 phase,220V/2 phase /material: copper

4.power distribution box

5.Time Relay

Technical Parameters of steel bar thread knurling machine

|

Max roll pressure |

180KN |

Spindle speed |

36,47,60,78 (r/min) |

|

Rolling material diameter |

6-50MM |

Active power |

5.5kw |

|

Track rollers |

120-170MM |

Hydraulic power |

2.2kw-4 |

|

Diameter rollers |

54MM |

Activities spindle feed speed |

5mm/s |

|

Max thickness of rollers |

100MM |

Dimensions |

1600*1550*1445mm |

|

Axis tilt angle |

± 3 °C |

Total mass |

1700kg ± 50kg |

|

Spindle center distance |

120-240MM |

Open thread length |

Plus protection |

Packaging & Shipping

Our Services

FAQ

Hot Searches