NaN / 0

Star Car Alloy Wheel Luxury Rim Rines 16 Inch 4 Hole 4 Spoke 100 114.3 PCD 20 25 ET 73.1 CB In Stock

Get Latest Price

US$ 73

≥4 Pieces

US$ 68

≥20 Pieces

US$ 62

≥40 Pieces

Quick Details

Finishing:

silver

Width:

7j 8.5j

Place of Origin:

Guangdong, China

Brand Name:

YQFY

Product Details

PRODUCTS DESCRIPTION

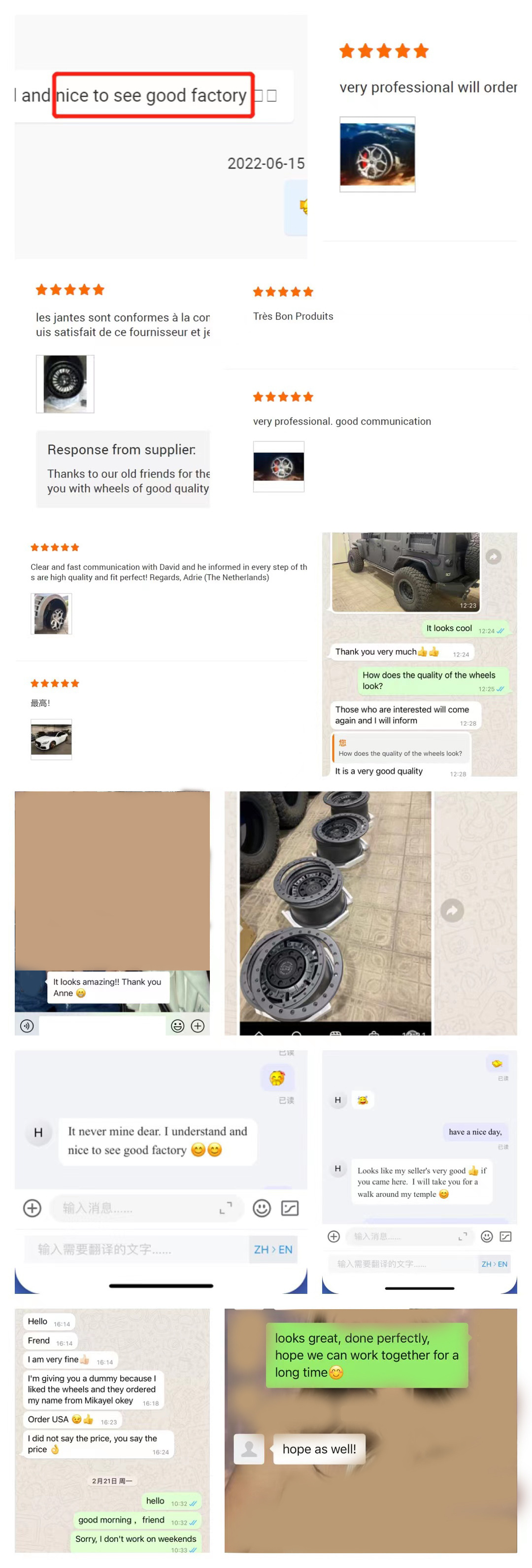

Customer Feedback

This is the customer's real evaluation of us, if you need to buy wheels for your customers or your car, please click the picture below to contact us, looking forward to your consultation.

One piece/monoblock Forged design

COMPANY INFORMATION

Exhibition

Two Piece Design More suitable for racing cars and modified personality cars

THE FORGING AND CASTING DIFFERENCE

|

Difference of Forged and Casted wheels

|

|

|

|

|

||||

|

Items

|

Forged wheels

|

|

Casted wheels

|

|

||||

|

Aluminun type

|

6061-T6

|

|

A365-T6

|

|

||||

|

Mechanical properties

|

1. tensile Strengthd>330Mpa

2. Yield Strength>300Mpa

3. Elongation>12%

|

|

1. tensile Strengthd>2600Mpa

2. Yield Strength>180Mpa

3. Elongation>9% |

|

||||

|

Features

|

1. Forging aluminum alloy material

Because there is no solid-liquid-solid transition of the material , the inseparable components such as segregation, loosening, and oxide inclusions are avoided.

2. After the forging process deforms the billet forging, the material structure becomes denser, do the mechanical properties of the material are higher.

3. the mechanical properties of all parts of the forging wheels are the same.

|

|

1. Due to casting molding reasons, castings have different mechanical properties at different locations due to different cooling conditions.

2. Spokes generally have an elongation of about 4% , while rims have an elongation of about 10%. therefore, the aluminum wheels produced by the casting process can only be used in the area of cars.

|

|

||||

|

Meet the needs of flat tires

|

the mechanical strength of the aluminum alloy wheel produced by the forging process is more suitable for the flat tire requirements of the vehicle

|

|

Unable to meet tire flatness requirements

|

|

||||

Delivery

FAQ

Title goes here.

1.How long i can receive after payment?

About 15-20 days send out after payment

2.Why do you support small orders?

Small batch orders can make our customers have no risk of stocking, customers can buy the products they need at any time, without worrying that the goods can't be sold.

3. How long can you ship for large quantities of orders?

For large orders, we will give customers proofs and quotations. After confirming the details, we will report the time to the

customer according to the order quantity. Custom Order, the produced time is 15-20 days.

4.Whats your shipping method?

A: To ensure you receive goods quickly,we will not choose cheaper sea shipping and method without any logistics

information.We will choose DHL,TNT,FeDex,UPS,SF_express.Also we can choose other shipping method as customer's request, such as by sea/by train/by land is cheapest.

5.How can i get the sample ?

We support sell sample,you need to pay sample fee is ok,you can get them about 3-5 days.

2.Why do you support small orders?

Small batch orders can make our customers have no risk of stocking, customers can buy the products they need at any time, without worrying that the goods can't be sold.

3. How long can you ship for large quantities of orders?

For large orders, we will give customers proofs and quotations. After confirming the details, we will report the time to the

customer according to the order quantity. Custom Order, the produced time is 15-20 days.

4.Whats your shipping method?

A: To ensure you receive goods quickly,we will not choose cheaper sea shipping and method without any logistics

information.We will choose DHL,TNT,FeDex,UPS,SF_express.Also we can choose other shipping method as customer's request, such as by sea/by train/by land is cheapest.

5.How can i get the sample ?

We support sell sample,you need to pay sample fee is ok,you can get them about 3-5 days.