NaN / 0

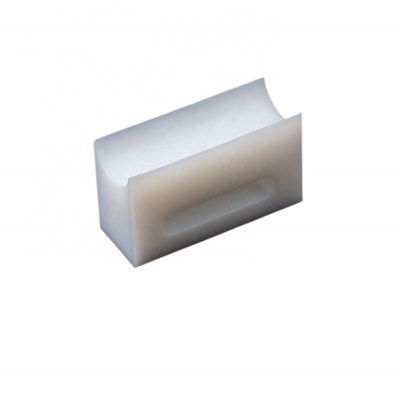

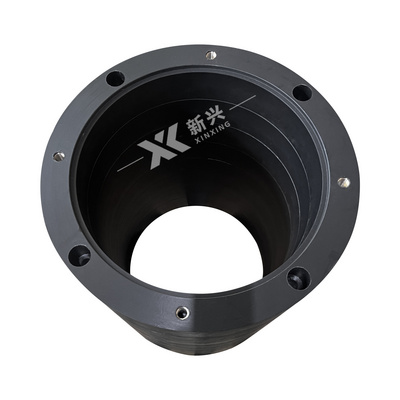

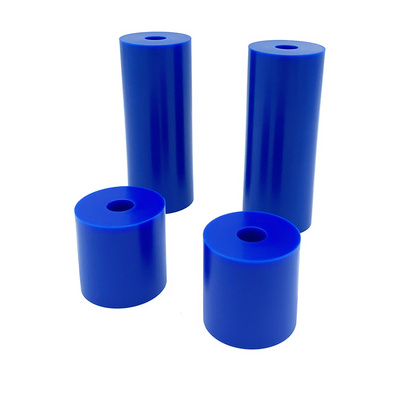

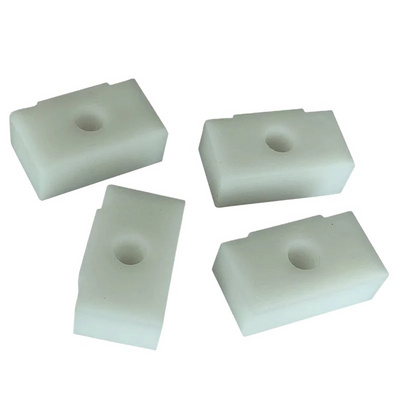

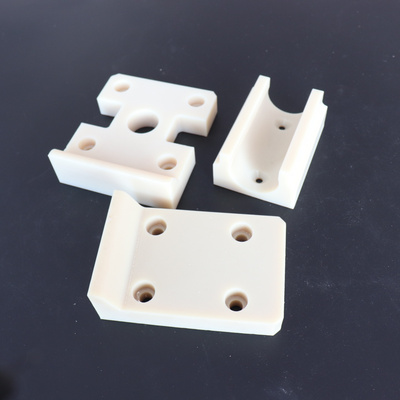

Top quality CNC machining nylon parts abs uhmwpe solid plastic block

Get Latest Price

US$ 1

≥100 Pieces

US$ 0.8

≥1000 Pieces

US$ 0.7

≥10000 Pieces

Quick Details

Processing Service:

Cutting, Moulding, CNC Turning, milling, drilling

Place of Origin:

Hebei, China

Brand Name:

KANGKE

Model Number:

Customized size

Product Details

|

item

|

value

|

|

Place of Origin

|

China

|

|

producer

|

Hebei

|

|

Brand Name

|

kangke

|

|

Model Number

|

002

|

|

Processing Service

|

Moulding, Cutting

|

|

Material

|

Plastic and rubber

|

|

Product name

|

Plastic products

|

|

Color

|

Customer's Request

|

|

Application

|

Mechanical accessories, industrial supplies, transportation accessories, daily necessities, etc

|

|

Feature

|

Eco-friendly

|

|

Type

|

Injection process and molding process

|

|

Advantage

|

Long Working Life

|

|

Quality

|

High Quaity

|

|

Service

|

One-stop Solution

|

Product Description

Custom Made CNC Machining Injection Plastic POM Roller Pulley

Cooperation with our factory directly for reasonable price, high quality, superior service and punctual delivery!

See What our Splendor Can do for you:

• Strong Technical Support: We have a technical R&D department with professional engineers, which can offer you with engineering

and technical design support in mold and product design.

• Strick Quality Control System: As a ISO 9001:2008 certificated manufacturer, we will offer you the high quality products.

• Superior Service: Our professional sales staffs would answer you in time, there is no communication problem.

• Stability and Reasonable Price: We are real factory, there is no middlemen commission, which can help you to save cost.

• Speed Delivery: Mould delivery time is 15-45 days according to its structure and size. 7-20days for mass production according to

order quantity.

See how to make your Mold for Plastic Parts :

01. Analysis Report Before Mold for Plastic Parts Making:

If necessary, we can send you analysis report for you learn mould design information before mould making.

02. Design 3D Mould Drawing

• Our Engineer will design 3D mould drawing for your confirmation.

• Design Software: Pro-E, Iges, UG, CAD etc

• Mould Base Material: LKM, HASKCO, LOCAL, DME etc

• Mould Core Material: 718H, S136H, NAK80, P20 ect

• Mould Cavity: Single & Multi Cavity

• Runner: Cold or Hot Runner

• Gate: Pinpoint Gate or Edge Gate

• Finish: Polish or Semi-matt

Cooperation with our factory directly for reasonable price, high quality, superior service and punctual delivery!

See What our Splendor Can do for you:

• Strong Technical Support: We have a technical R&D department with professional engineers, which can offer you with engineering

and technical design support in mold and product design.

• Strick Quality Control System: As a ISO 9001:2008 certificated manufacturer, we will offer you the high quality products.

• Superior Service: Our professional sales staffs would answer you in time, there is no communication problem.

• Stability and Reasonable Price: We are real factory, there is no middlemen commission, which can help you to save cost.

• Speed Delivery: Mould delivery time is 15-45 days according to its structure and size. 7-20days for mass production according to

order quantity.

See how to make your Mold for Plastic Parts :

01. Analysis Report Before Mold for Plastic Parts Making:

If necessary, we can send you analysis report for you learn mould design information before mould making.

02. Design 3D Mould Drawing

• Our Engineer will design 3D mould drawing for your confirmation.

• Design Software: Pro-E, Iges, UG, CAD etc

• Mould Base Material: LKM, HASKCO, LOCAL, DME etc

• Mould Core Material: 718H, S136H, NAK80, P20 ect

• Mould Cavity: Single & Multi Cavity

• Runner: Cold or Hot Runner

• Gate: Pinpoint Gate or Edge Gate

• Finish: Polish or Semi-matt

Hot Searches