NaN / 0

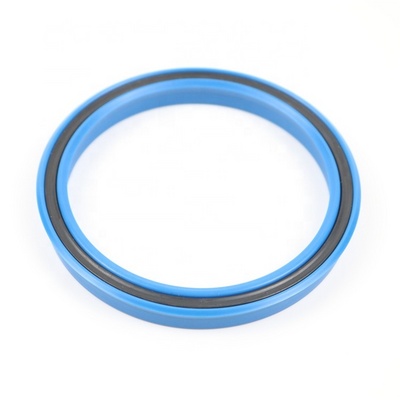

Piston Rod Excavator Oil Cylinder Main Oil Seal 100*120*12 IUH Main Oil Seal

Get Latest Price

US$ 0.55

≥100 Pieces

US$ 0.47

≥1000 Pieces

US$ 0.39

≥10000 Pieces

Quick Details

Size:

can be customized, Standard Size and customize

Place of Origin:

Guangdong, China

Brand Name:

OEM

Model Number:

UFO113, Standard

Product Details

Custom is welcome ,let us build your makeup brand now:)

silicone o-ring for machinery car seals are one of the most common seals used in machine design,it can be used in static applications or in dynamic applications where there is relative motion between the parts and the O-ring. Dynamic examples include rotating pump shafts and hydraulic cylinder pistons.

|

Product Name

|

Rubber o ring for sealing

|

|

Material

|

NBR, HNBR, EPDM, SILICONE, VITON, FLS, FFPM, PTFE

|

|

Color

|

Green,red, black, etc.

|

|

Sizes

|

Standard or customized size

|

|

Mould Cavity

|

Single or multi cavity

|

|

Mould Life

|

100,000 to 500,000 shots

|

|

Production Technique

|

Compression moulding

|

|

Temperature

|

NBR(-40~120°C),FFKM(-20~320°C)

Viton(-20~200°C),Silicone (-70~220°C) EPDM(-50~150°C),PU(-40~90°C) |

|

Feature

|

Resistance to high pressure, oil, weather, abrasion, solvent, high temperature, abrasion resistant, aging resistant, insulation,

acid and alkaline resistant |

|

Cerfiticate

|

ISO 9001:2008

|

|

Hardness

|

30-90 shores A

|

|

Color

|

Red, Black, White, blue, green, Clear, etc

|

|

Size

|

Any size, Customized/standard and nonstandard

|

|

Sample time

|

If instock, within 3 days after payment

|

|

Delivery time

|

3-7 days by express after payment

7-15 days by ship |

|

Shipping

|

Small quantity: UPS/FeDex/DHL express

Large quantity: by Air/Sea |

|

Customized

|

OEM & ODM are welcomed

|

|

packing

|

plastic bag&carton box or according to your requirements

|

|

Application

|

chemical industry, petroleum industry, medical technique, food industry, sewage-disposal industry, steel industry, semi-conduct

industry and so on. |

Material performance

|

Material Type

|

Temperature description

|

Performance

|

Advantages

|

|

NBR

|

-25~100℃

|

1.Oil resistant, water resistance.

2.Good compression slanting, anti-wear and elongation. |

Excellent resistant to oil, widely used in industrial area.

|

|

FKM, FPM

|

-20~250℃

|

1.Corrosion resistance.

2.High temperature resistance. 3.Antistatic. |

Excellent resistance to high temperature and a broad range of chemical, permeability and compression set are excellent.

|

|

CR

|

-50~150℃

|

1.Oil resistant, water resistance.

2.Flameproof. |

Generally good resistance to ozone, aging and chemical, good mechanical properties over a wide temperature range

|

|

Silicone rubber

|

-30~150℃

|

1. Corrosion resistance.

2. High temperature resistance. |

Widest operating temperature range, performance stably in high and low temperature, widely used in food sealing area.

|

|

NR, natrual rubber

|

-25~150℃

|

1.Wear resistance.

2.Heat resistance. |

High elasticity, good chemical strength.

|

|

HSN, HNBR

|

-62~210℃

|

1.Oil resistant.

2.Temperature resistance. |

Thermal stability and oxidation resistance.

|

|

ASTM/DIN ISO

|

NBR

|

ACM

|

VMQ

|

HNBR

|

PTFE

|

FKM

|

|

Wear Resistance

|

very good

|

moderate

|

moderate

|

moderate

|

good

|

very good

|

|

High Temperature Resistance

|

moderate

max 125C |

good

max 150C |

very good

max 225C |

good

max 150C |

good

max 260C |

very good

max 250C |

|

Low Temperature

Resistance |

-40C

|

-30C

|

-60C

|

-25C

|

-65C

|

-20C

|

|

Oil Resistance

|

good

|

good

|

moderate

|

good

|

extremely good

|

extremely good

|

|

Chemical Resistance

|

good

|

moderate

|

moderate

|

good

|

very good

|

good

|

1. Rubber o rings is widely in many different fields. Includes industry, equipment, house, toys, kitchen, shower, car, air...even

fasion parts.

2. O rings with different material, is used on different industry. It is related with working condition, application temperature,

contacting medium, uses, pressure...

fasion parts.

2. O rings with different material, is used on different industry. It is related with working condition, application temperature,

contacting medium, uses, pressure...

|

Packing Type

|

Inner PE bag + outer carton box, (100 ~1000) pieces/bag; 5~10 bag /carton box

or customized according to specific requirements from clients |

|

Packing Material

|

Inner PE film + outer carton box, palletized for extra reinforcement if necessary

|

|

Shipping Marks

|

Neutral packing with printed marks.

|

|

Lead Time

|

Production lead time: 1~3 days after receiving of PO and advance payment (30%)

|

|

Delivery Time

|

100% meet customer delivery requirement and can be expedited for special case

|

|

Freight

|

Sea (FCL & LCL) or air freight

|

Q: Can l get the sample?

Yes, we can provide you existing sample for free, but a little sample charge for custom design, new customers are expected to pay for the delivery cost, the sample charge will be deducted from the payment for formal order.

Q: How long is the sample lead time?

For existing product, it takes 1-2 days;, lf you want your design, it may take 3-5 days depends on your design content.

Q: How about your product quality control?

We have our QC department empowered with a professional QC team. "Quality First, Cutomer Focus" is our quality policy, and we have incoming Quality Control / in-process Quality Control /Out-going Qualtiy Control throughout our factory operations.

Q:Why should l buy this silicone rubber o ring?

This silicone rubber o ring offers excellent quality, reasonable price, good after-sales service & quality assurance.