NaN / 0

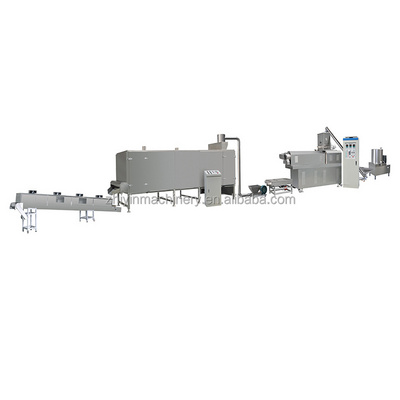

Rice Extruder Twin-screw Extruder Corn Flakes Cereal Puffing Instant Cooking Processing Equipment Snack Puffed Production Line

Get Latest Price

US$ 18900

≥1 Sets

US$ 18000

≥3 Sets

US$ 17500

≥5 Sets

Quick Details

Marketing Type:

New Product 2023

Place of Origin:

Shandong, China

Brand Name:

ZHIYIN

Voltage:

220V/380V

Product Details

Product Description

Rice Extruder Twin-screw Extruder Corn Flakes Cereal Puffing Instant Cooking Processing Equipment Snack Puffed Production Line

Rice Extruder Twin-screw Extruder Corn Flakes Cereal Puffing Instant Cooking Processing Equipment Snack Puffed Production Line

Industrial food extruder, rice grain extruder, grain and rice production line

The twin-screw extruder is composed of two co-rotating high-torque screws that mesh with each other. Due to the wide design range of the screw and barrel, various screw profiles and process functions can be set according to the process requirements, so the twin-screw extruder can be High-strength flexibility ensures transportation, compression, mixing, cooking, shearing, heating,cooling, pumping, molding, etc.

The purpose of extrusion processing is to physically and chemically convert the viscous polymer medium through precise control of processing conditions , And produce high-quality structured products.

The flexibility and visualization of the adjustment of process parameters can be widely used in many fields in the food industry.

It is an ideal choice for processing breakfast cereals, snack foods, food raw materials, modified starches, pet foods, etc.

The twin-screw extruder is composed of two co-rotating high-torque screws that mesh with each other. Due to the wide design range of the screw and barrel, various screw profiles and process functions can be set according to the process requirements, so the twin-screw extruder can be High-strength flexibility ensures transportation, compression, mixing, cooking, shearing, heating,cooling, pumping, molding, etc.

The purpose of extrusion processing is to physically and chemically convert the viscous polymer medium through precise control of processing conditions , And produce high-quality structured products.

The flexibility and visualization of the adjustment of process parameters can be widely used in many fields in the food industry.

It is an ideal choice for processing breakfast cereals, snack foods, food raw materials, modified starches, pet foods, etc.

Specification

Rice Extruder Twin-screw Extruder Corn Flakes Cereal Puffing Instant Cooking Processing Equipment Snack Puffed Production Line

|

Model

|

ZYCP65

|

ZYCP70

|

ZYCP75

|

ZYCP85

|

|

Installed Power

|

130kw

|

160kw

|

256kw

|

205kw

|

|

Capacity

|

100-120kg/hour

|

200-260kg/hour

|

200-350kg/hour

|

300-500kg/hour

|

|

Dimension

|

39×1.5×2.5m

|

41×1.5×2.5m

|

52×1.5×2.6m

|

45×1.5×2.6m

|

System optional configuration

1. Control system: ordinary control cabinet, intelligent control cabinet.

2. Power module: conventional power module, heavy-duty power module, high-torque power module.

3. Feeding system: single screw feeding, twin screw feeding, intelligent metering feeding.

4. Barrel module: integral barrel, wear-resistant composite barrel.

4. Barrel module: integral barrel, wear-resistant composite barrel.

5. Temperature control system: electric temperature control,steam temperature control, mold temperature and machine temperature.

6. Extrusion die: customized according to process requirements.

7. Rotary cutting and blanking system: forward and side rotary cutting.

8. Host base: carbon steel spray frame, stainless steel frame.

Food Puffing Extruder Corn Flakes Cereal Puffing Instant Cooking Processing Equipment Snack Puffed Food Production Line

|

Rice Extruder Twin-screw Extruder Nutrition Rice Extruder Machinery Automatic Instant Rice Artificial Rice Nutritional

|

|

|

|

|

||||

|

NO.

|

Name

|

Dimensions

|

Power

|

Product usage

|

||||

|

1

|

Mix machine

|

1260*800*1200mm

|

75kw

|

Used for mixing raw corn flour with a small amount of liquid.

|

||||

|

2

|

Screw feeding machine

|

3100*590*2200mm

|

0.75kw

|

The mixed material is conveyed to the feed hopper of the extruder by a screw conveyor.

|

||||

|

3

|

Twin screw extruder

|

5000*1200*1500mm

|

165kw

|

The twin-screw dry extruding extruder is used to extrude the mixed corn flour instantaneously and produce high expanded granules.

|

||||

|

4

|

Vibrating screen

|

1530*820*790mm

|

0.55kw

|

Removal of debris after the formation of highly expanded particles.

|

||||

|

5

|

Air pressure conveyor

|

1200*530*2500mm

|

1.1kw

|

The high compression particles are transported to the Tableting machine by air transport mode.

|

||||

|

6

|

High temperature oven

|

8710*1490*1845mm

|

1.5kw

|

The corn flakes are puffed again at high temperature in the oven to achieve a more

|

||||

|

7

|

Cooling line

|

5000*500*750mm

|

0.75kw

|

After spraying sugar on the cornflakes out of the dryer after cooling.

|

||||

ZHENGZHOU ZHIYIN INDUSTRY CO.,LTD

We areset food machinery design, processing, production as one of the industry and trade of the company.Its product cases include potato chip production line, banana chip processing machine, snack food production machine, meat processing machine, industrial food frying line, vacuum frying machine, low temperature freezing production line, etc.

After years of development, it has formed a series of perfect systems for raw material supply, product development, process design, finished product inspection, production management, storage and transportation, and technical services.

Food production line:

Potato chip production line, potato chip production line, frozen potato chip production line, banana chip production line, cassava production line, snack frying production line, jam production line, nut production line, peanut butter production line.

Frying machinery:

Vacuum fryer, French fries freezing line, snack fryer and other equipment.

Meat processing machinery:

Cooking pot series,tumbler, meat grinder, stuffing machine, meat grinder,meat processing equipment, etc.

Vegetable and fruit processing machinery:

Vegetable washing machine, leafy vegetable vortex cleaning agent, pasteurizer, vegetable peeling machine, garlic peeling machine, juicer, vibrating screen, fruit grading machine, soft packaging pasteurization machine, vegetable diced drying machine,etc. .

Food packaging:

snack packaging machine, automatic weighing packaging machine, liquid filling machine, labeling machine,etc..

Vegetable cutting equipment:

Vegetables and fruits are sliced, diced, diced, etc.

Food refrigeration:

French fries freezer, food freezer, seafood quick freezer, food low-temperature tunnel freezer, food-grade constant temperature warehouse.

Food drying:

Natural food dryer, food hot air dryer, snack dryer, rice puffing machine.It can be widely used in the processing and production of various meat products, soybean products, dairy products, egg products, seafood, beverage products, snack foods, and processing equipment for agricultural products and Chinese medicinal materials.

1.Why choose us?

Q:

If you have your own food processing plant,in addition to food safety,how to improve production efficiency is one of the issues that should be considered.

2.

What can we do for the food factory?

Q:

We can design a complete implementation plan for the factory and design CAD drawings free of charge according to the size of the workshop.

3.

How to choose capacity?

Q:

Our potato chips and other production lines, support capacity customization 100-2000kg/hour.

4.

I'm a food processing plant. What should I do with a new plan?

Q:If you are a local trader of food machinery,how to improve the product and service is one of the issues to consider.

If you have a local market,then our investment policy may be the best for you,which solves your inventory cost. For more investment policy,please check out Food Machinery Manufacturer.

Hot Searches