NaN / 0

Automatic Electric Eggplant Tomato Carrot Potato Onion Vegetable Dicing Machine for Fruit Pineapple Mango Apple Cube

Get Latest Price

US$ 1650

≥1 Sets

US$ 1600

≥5 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

Etornuo

Model Number:

ETOVC100D

Type:

Fruit and Vegetable Cutting Machine

Product Details

Automatic Electric Eggplant Tomato Carrot Potato Onion Vegetable Dicing Machine for Fruit Pineapple Mango Apple Cube

Product Description

Introduction of Model ETOVC100D Vegetable Dicing Machine

1.Multifunction

The vegetable dicing machine is widely used for cutting many kinds of root, stem, bulb vegetables and fruits into cubes or cuboids.

2.Types of Cutters

The machine has one set of compound cutters such as strip, slice and cube cutter.

It can cut vegetables and fruits into different sizes of cubes or cuboids by changing the related cutters.

That is to say, with only one machine, customers can get different sizes of finished products.

3.Scope of Application

Vegetables: Potato, sweet potato, carrot, parsnip, radish, turnip, kohlrabi, beet root, lotus root, bamboo shoot, yam, taro, garlic, ginger, onion, pumpkin, zucchini, cucumber, eggplant, tomato, mushroom, etc.

Fruits: Pineapple, papaya, apple, pear, peach, mango, kiwi fruit, apricot, strawberry, etc.

4.Widely Commercial Application

It is suitable for the bakery, canteen, restaurant, hotel, dining hall of school, kindergarten, factory, frozen food factory, farm, vegetable processing plant, fruit processing plant, etc.

5.Advantages

a. The machine base, housing, hopper and main components are made of food grade SUS304 stainless steel and corrosion resisting aluminum magnesium alloy.

b. It is characterized by easy operation and installation, easy maintenance, low energy consumption, safety and healthy, high efficiency.

c. The famous brand electrical apparatus elements are used for the machine.

d. The voltage can be customized.

e. The size of cubes can be 3mm/4mm/5mm/6mm/8mm/10mm/12mm/15mm, or other size customized.

f.

The machine adopts

compound cutter, one-time forming, switching rules, smooth cutting surface and high forming rate,

which is favored by customers.

g.

The shape of vegetables and fruits that have been processed by the machine is regular, the profile of them is smooth and the shaping rate is high.

6.Working Principle

The drive plate of this machine can drive the vegetables and fruits to rotate in high speed, vegetables and fruits are cut into slices making use of centrifugal force with upright slice cutter and then cut into strips through strip cutter. Finally, the vegetables and fruits are transported to the cross cube cutter and have been cut into cubes or cuboids as required.

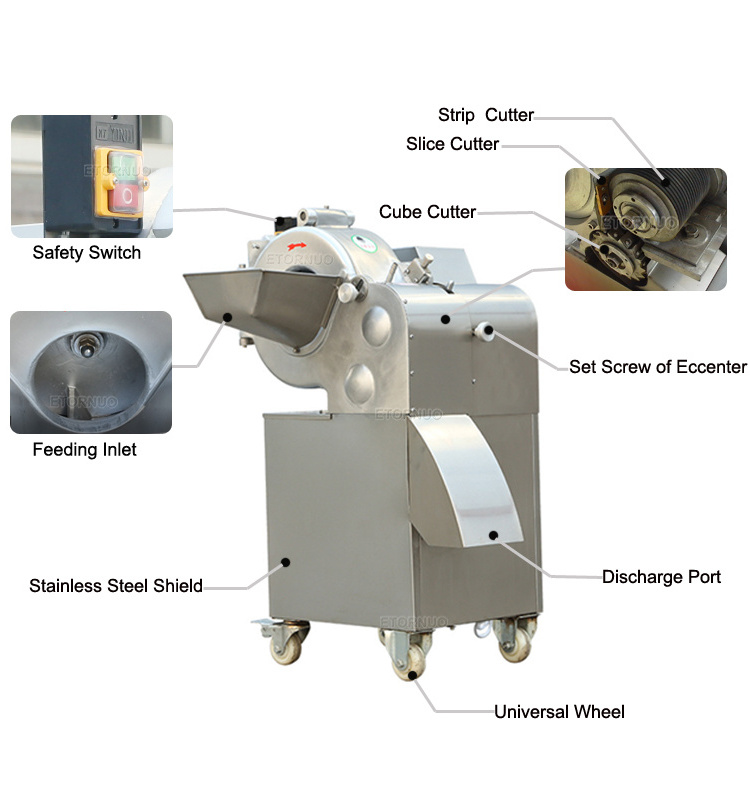

Structure of Model ETOVC100D Vegetable Dicing Machine

The vegetable dicing machine consists of safety switch, compound cutters , feeding inlet, set screw of eccenter, 304 stainless steel shield, discharge port, universal wheel, etc.

Technical Parameters

A.Technical Parameters of Vegetable Dicing Machine for Cube

| Model | Voltage | Power |

Capacity |

Dimension | Weight |

| ETOVC100D |

110V/220V/380V/415V 50Hz/60Hz |

0.75kw | 1000kg/h | 560x600x1310mm | 100kg |

B.Technical Parameters of Vegetable Dicing Machine for Slice, Strip, Julienne, Cube, Section, Piece, Wave and Rhombus

| Model | Voltage | Power |

Capacity |

Dimension | Weight |

| ETOVC1000A |

110V/220V/380V/415V

50Hz/60Hz |

1.5kw | 200-1000kg/h | 1300x600x1050mm | 240kg |

| ETOVC660A |

110V/220V/380V/415V

50Hz/60Hz |

0.75/0.8kw | 150-660kg/h | 900x460x740mm | 140kg |

| ETOVC660B |

110V/220V/380V/415V

50Hz/60Hz |

0.75/0.8kw | 150-660kg/h | 900x460x740mm | 150kg |

| ETOVC2000 |

110V/220V/380V/415V

50Hz/60Hz |

1.5kw | 500-2000kg/h | 1320x730x900mm | 290kg |

| ETOVC1000 |

110V/220V/380V/415V

50Hz/60Hz |

1.5kw | 200-1000kg/h | 1300x600x900mm | 170kg |

| ETOVC660 |

110V/220V/380V/415V

50Hz/60Hz |

0.75kw | 150-660kg/h | 900x460x740mm | 115kg |

C.Technical Parameters of Vegetable Dicing Machine for Slice, Strip, Julienne, Cube, Section and Piece

| Model | Voltage | Power |

Capacity |

Dimension | Weight |

| ETOVC850A |

110V/220V/380V/415V 50Hz/60Hz |

2.75kw | 850kg/h | 1165x550x1255mm | 170kg |

| ETOVC860A |

110V/220V/380V/415V 50Hz/60Hz |

1.87kw | 860kg/h | 1165x600x1255mm | 180kg |

| ETOVC900A |

110V/220V/380V/415V 50Hz/60Hz |

2.25kw | 2000kg/h | 1420x670x1500mm | 175kg |

D.Technical Parameters of Vegetable Cutting Machine for Slice, Strip, Julienne, Section and Piece

| Model | Voltage | Power |

Capacity |

Dimension | Weight |

| ETOVC20 |

110V/220V

50Hz/60Hz |

1kw | 120-450kg/h | 595x460x600mm | 55kg |

| ETOVC40 |

110V/220V

50Hz/60Hz |

0.75kw | 400kg/h | 590x660x1115mm | 95kg |

| ETOVC80 |

110V/220V/380V/415V

50Hz/60Hz |

1.6kw | 80-2000kg/h | 1200x660x1000mm | 155kg |

| ETOVC80A |

110V/220V/380V/415V

50Hz/60Hz |

1.85kw | 80-2000kg/h | 1200x660x1000mm | 160kg |

| ETOVC80B |

220V/380V/415V

50Hz/60Hz |

2.4kw | 80-2000kg/h | 1350x660x1000mm | 180kg |

| ETOVC150 |

220V/380V/415V

50Hz/60Hz |

4.05kw | 150-3000kg/h | 1470x775x1330mm | 270kg |

| ETOVC200P |

110V/220V

50Hz/60Hz |

0.75kw | 120-350kg/h | 440x365x570mm | 45kg |

| ETOVC100S |

220V/380V/415V

50Hz/60Hz |

2.6kw | 1000kg/h | 730x520x955mm | 135kg |

| ETOVC100H |

110V/220V/380V/415V

50Hz/60Hz |

1.5kw | 1000kg/h | 900x1010x840mm | 125kg |

| ETOVC100F |

110V/220V

50Hz/60Hz |

1.1kw | 1000kg/h | 1070x685x1030mm | 120kg |

| ETOVC500M |

110V/220V/380V/415V

50Hz/60Hz |

0.75kw | 500kg/h | 1800x700x960mm | 165kg |

E.Technical Parameters of Vegetable Cutting Machine for Filling

| Model | Voltage | Power |

Capacity |

Dimension | Weight |

| ETOVC30F |

110V/220V/380V/415V 50Hz/60Hz |

1.1/1.5kw | 300kg/h | 775x715x950mm | 130kg |

| ETOVC880S |

220V/380V/415V 50Hz/60Hz |

1.5kw | 880kg/h | 750x440x1020mm | 70kg |

Detailed Images

Packaging & Shipping

Packing Materials

The vegetable dicing machine is packed with the following two parts:

1.

Water proof film

2.

Standard exporting fumigation-free plywood case

Mode of Transportation

1.

The vegetable dicing machine will be sent to you

by sea, by air or by international express

according to the

volume and weight

of cargo.

2. The delivery time is 3-5 days after confirming the advance payment.

2. The delivery time is 3-5 days after confirming the advance payment.

Our Services

1. Quality warranty period is two years. Equipment must be 100% brand new when leaving factory.

2. Whole lifetime maintenance free of charges.

3. Free training course at our plant.

4. Free technical support online or by phone communications and emails.

5. Our engineer can be assigned to your country for testing and training as per your requirement.

FAQ

Q1:What’s the payment terms?

A1: T/T, Trade Assurance, Western Union, MoneyGram, L/C, Cash, etc.

Q2:What is the function of this machine?

A2:

The

vegetable dicing machine

can cut

vegetables and fruits

like

eggplant, cucumber, zucchini, pumpkin, tomato, onion, taro, beet root, kohlrabi, carrot, potato, strawberry, apricot, kiwi fruit, mango, peach, pear, apple, papaya, pineapple, etc.

into

different sizes

of

cubes or cuboids

by changing the related

compound cutters such as strip, slice and cube cutter.

Q3:What’s the materials of machine?

A3:

It

is made of

304

stainless steel materials and a

luminum magnesium alloy materials.

Q4:What about the warranty?

A4:Quality warranty period

for this machine is

two years

.

Malfunctions which are caused by

machine-self and quality

will be responsible for

supplier

. The

spare parts

will be sent to you

free of charge.

Hot Searches