NaN / 0

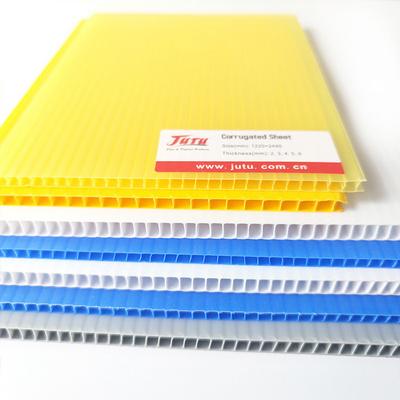

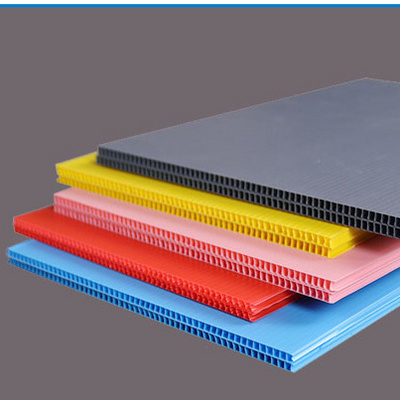

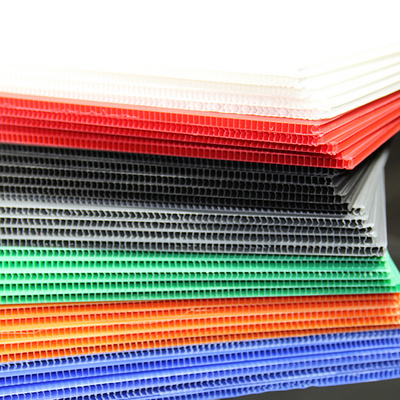

PP hollow sheet extrusion machine/ Plastic PP fluted corrugated sheet production line

Get Latest Price

US$ 25000

≥1 Sets

Quick Details

Screw Design:

Single-screw

Model Number:

SJ100/33F

Place of Origin:

Jiangsu, China

Brand Name:

VICTOR, Victor

Product Details

plastic hollow board making machine

Product Description

This PET sheet extrusion line is equipped three-roller calander, with high performance vented extruder, die, screen change system, cooling rocket, haul-off unit, cutting unit and etc. specially designed for producing APET, PETG

and CPET single-layer and multi-layer sheet with thickness of 0.12mm to 5 mm and width of 500mm to 3000mm. It can be for produce PS,PP and PE sheet also.

Technical Paramters

Main Technical Paramters

|

Extruder model |

SJ100/33F |

SJ120/33F |

|

Width of sheet |

500-950mm |

500-1500mm |

|

Thickness of sheet |

0.15-1.4mm |

0.15-1.4mm |

|

Main driving motor |

90KW |

132KW |

|

Max.production speed |

30m/min |

28/min |

|

Max.extrusion capacity |

250kg/hr |

550kg/hr |

Application

Products Application:

Vacuum Forming:food packager,toy box,stationery case,tool and hardware packing

Obstruct Packing:for electronic components packing

Normal Application:folded forming,collar lining,decoration material,file folder,document cover,credit card.

Special Application:medical instrument packing,medicine packing,industrial anti-sepsis,roast tray of microwave oven(CPET)

Vacuum forming : food packager; toy box; stationery case; tool and hardware packing

Obstruct packing : for electric components packing

Normal application : folded forming; collar lining; decoration material; file folder; document cover; credit card

Special application : medical instrument packing; medicine packing; industrial anti-sepsis; roast tray of microwave oven(CPET)

Characteristic

plastic hollow board making machine Characteristic

Machinery line is composed of extruder, screen exchanger, melt pump, die, three roll calender, downstream machinery line.

Features

Product Feature:

PET sheets,has the feature of excellent processing capacity,high transparency,innocuity,no small and non pollution,easy to be recycled.It is particularly good for medicine packing.

Packaging & Shipping

Hot Searches