NaN / 0

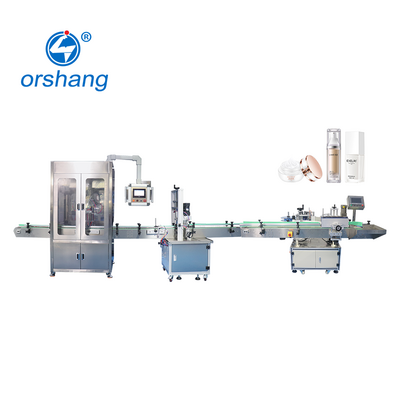

Full Automatic 2 Heads Shampoo and Liquid Soap Production Line Chemical Hand Wash Liquid Detergent Soap Filling Capping Machine

Get Latest Price

US$ 15000

≥1 Pieces

US$ 5000

≥10 Pieces

Quick Details

Machinery Capacity:

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

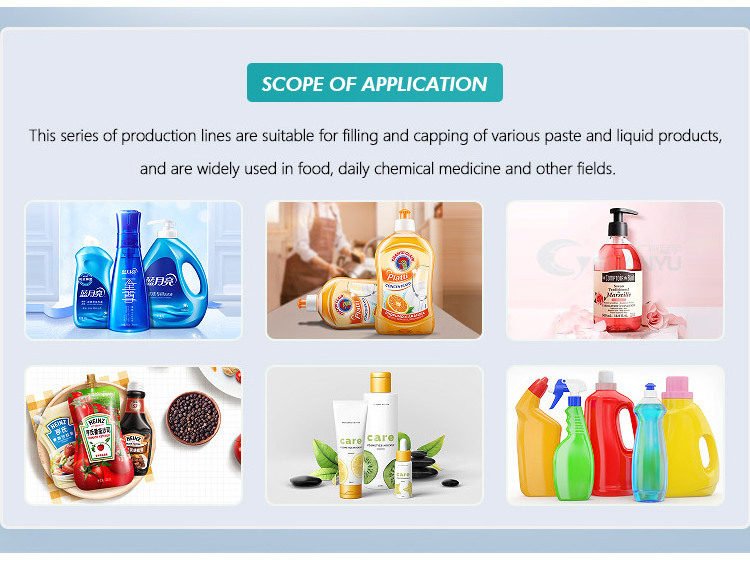

Packaging Material:

Glass, Plastic, Metal

Filling Material:

Milk, Water, Oil, Juice, Powder, Liquid

Filling Accuracy:

0.5%

Product Details

Product configuration

|

Max filling speed

|

filling 200ml, 2000~3000 pcs/hour, speed will be different when bottle shape and neck size and the filling material forming and

other physical property |

|

Applicable bottle diameter size

|

30-300(mm)

|

|

Applicable bottle height size

|

30-350(mm)

|

|

Filling dose

|

200~ 2000ml (Customizable)

|

|

Filling accuracy

|

±0.5% — ±0.8%

|

|

Voltage

|

AC220V, single phase, 50/60HZ

|

|

Power

|

4.5 KW

|

|

Working pressure

|

0.55-0.65 Mpa

|

|

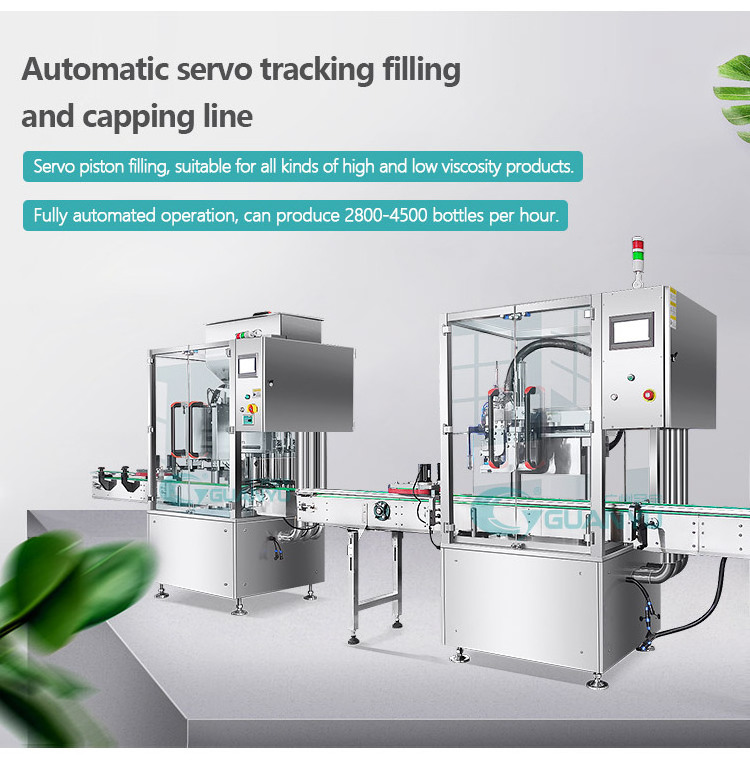

Filling method

|

Servo piston tracking

|

|

Program control

|

PLC+touch screen man-machine interface

|

|

Capping speed

|

2000-3000 bottles/hour

|

|

Lower cover way

|

Manual or vibrating plate

|

Main Features(Filling machine):

1、Tracking filling method, there is no need to intercept bottle filling like the traditional method during filling, and the filling action is completed during the bottle movement.

1、This machine is equipped with a parameter storage system. When changing the bottle size or filling volume, just press a key on the touch screen to adjust.

2、The cylinder drives the diving of the filling nozzle and matched with the variable filling speed which can reduce foaming when filling which can avoid polluting the bottles.

3、On the man-machine interface, the filling volume of different filling heads can be individually fine-tuned.

4、The material level sensor is used to check the level position under normal running of the machine,plus with high and low level check and alarm device. The level inspection device is made of PTFE, with perfect anti-corrosion feature.

5、Machine body is made by 304 stainless steel, easy to clean, machine is full compliance with GMP requirements.

Main Features(Capping machine):

1.Tracking screw capping method, there is no need to intercept the bottle capping like the traditional way when capping, and the capping action is completed during the bottle movement.

2.This machine is equipped with a parameter storage system. When changing the bottle size, just press a key on the touch screen to adjust it.

3.This machine adopts full servo control, including the height of the capping head, the translation speed of the capping claw, and the capping torque control.

4.According to different packaging materials, you can choose to use different capping heads.

5.Which adopt identity torsion capping head, the capping device could not hurt the cap .

6.Which can be match with packing line.

About Us

Certifications

FAQ

Hot Searches