NaN / 0

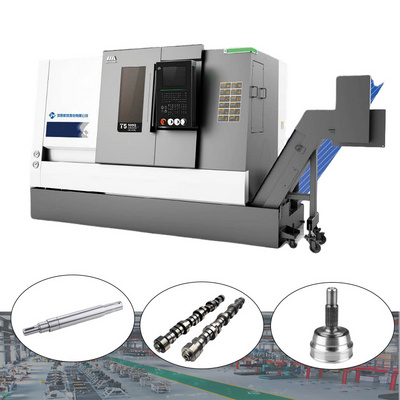

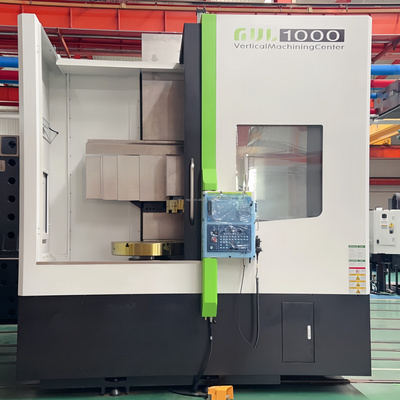

GVL1000 CNC Vertical Lathe Turning and Milling Machine Center New Condition Best Price

Get Latest Price

US$ 113000

≥1 Pieces

US$ 107000

≥5 Pieces

US$ 98400

≥10 Pieces

Quick Details

Type:

VERTICAL

Max. Length of Workpiece (mm):

1150

Year:

NEW

Max. Spindle Speed (r.p.m):

1000 r.p.m

Product Details

Product Overview

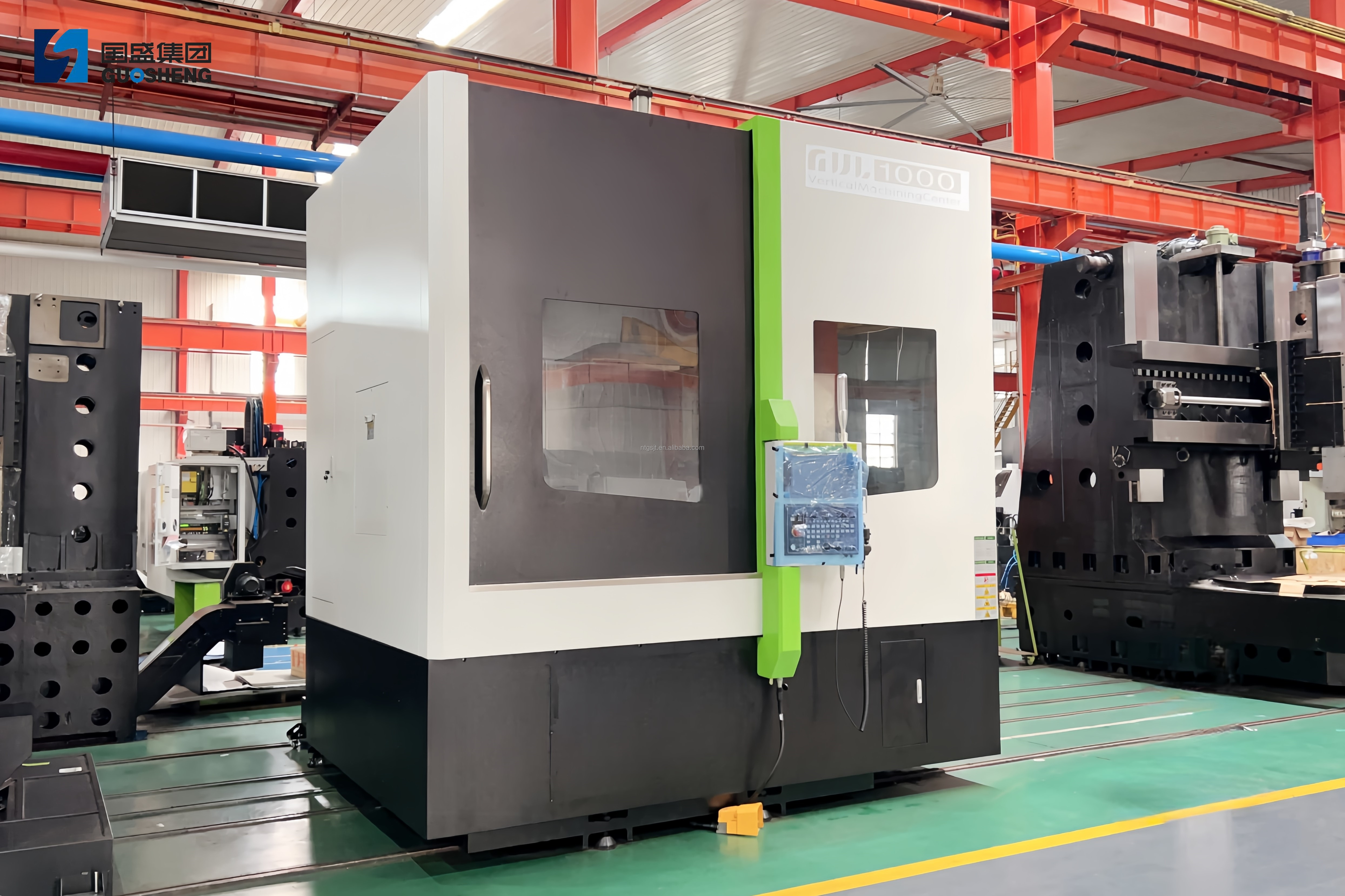

GVL1000 CNC Vertical Lathe Turning and Milling Machine Center New Condition Best Price

This series of models is mainly used in disk parts processing, is the standard model in the Guosheng product series.

The main shaft adopts double row cylindrical roller bearings and high-speed thrust angular contact ball bearings in front bearings, and double row cylindrical roller bearings in rear bearings.

FEATURES AT A GLANCE

X/Z axis rail slider.

The inner diameter of the main shaft bearing with the same specification, the suitable wide spacing between the lead screw and the guide rail.

The servo motor drives the X/Z axis ball screw and prestretches both ends of the screw screw.

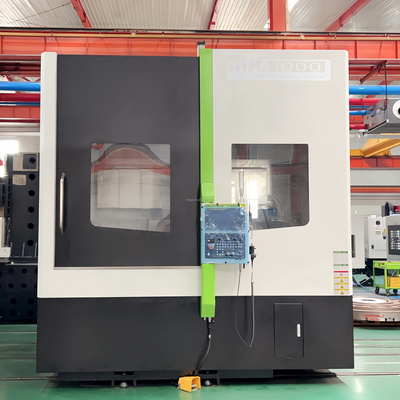

Complete enclosed protection.

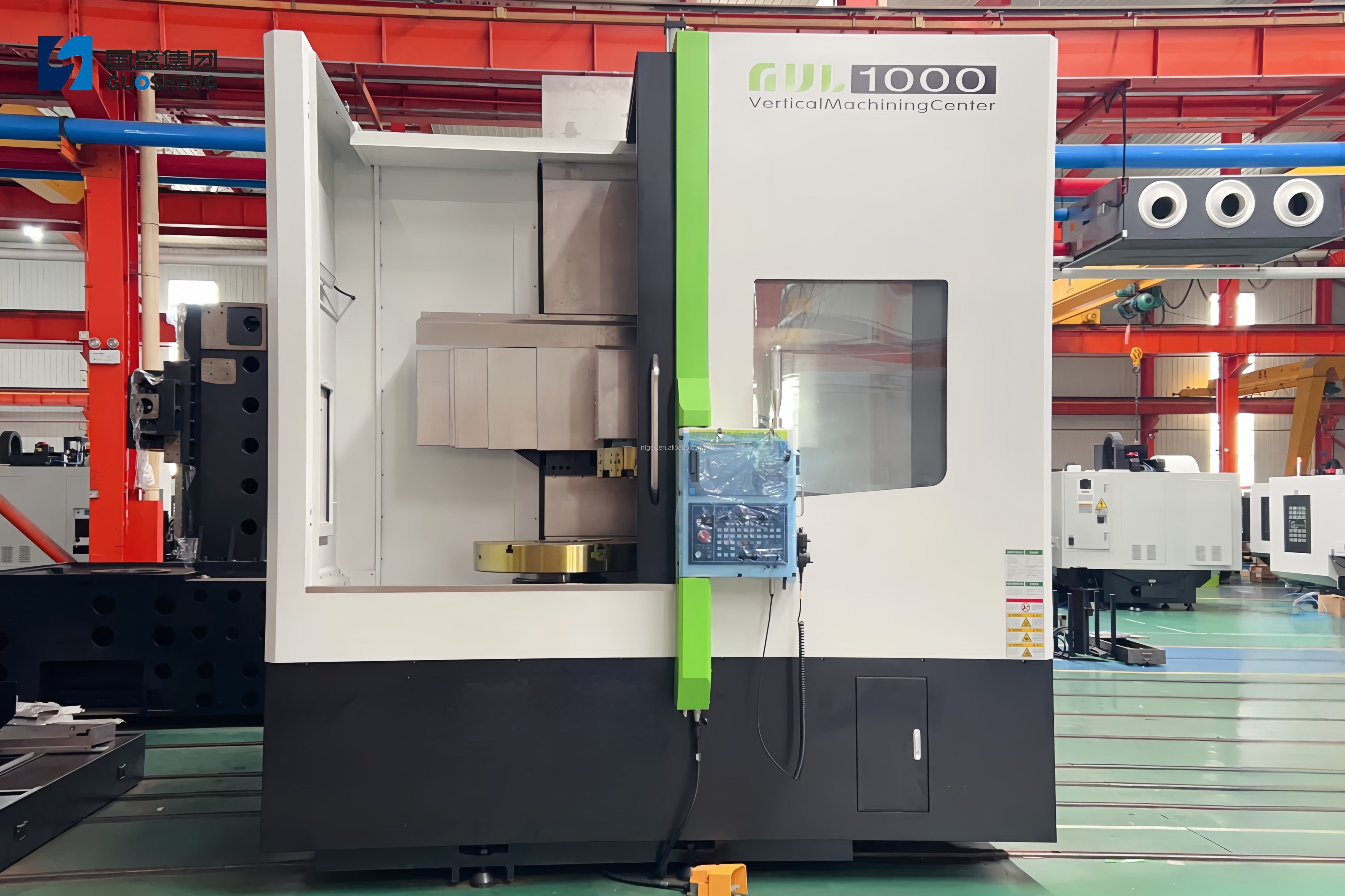

Right elevation

Left elevation

Inside elevation

PRODUCT SPECIFICATIONS

|

Machine Type

|

Unit

|

GVL1000

|

||

|

Spindle

|

|

|

||

|

Spindle head

|

mm

|

A2-15

|

||

|

Maximum spindle speed

|

rpm

|

1000

|

||

|

Maximum torque

|

Nm

|

2600

|

||

|

Spindle power

|

Kw

|

18.5/22

|

||

|

Self-centering chuck diameter

|

mm

|

800

|

||

|

Spindle bearing diameter

|

mm

|

220

|

||

|

Range of speed

|

rpm

|

72-1000

|

||

|

Processing range

|

|

|

||

|

Maximum diameter

|

mm

|

1150

|

||

|

Maximum diameter can be machined

|

mm

|

1000

|

||

|

Maximum machining height

|

mm

|

1000

|

||

|

Standard machining diameter

|

mm

|

800

|

||

|

X-axis travel

|

mm

|

900

|

||

|

Z-axis travel

|

mm

|

1030

|

||

|

System configuration

|

|

FANUC 0i TF

|

||

|

X-axis motor

|

|

aiF22-3000

|

||

|

|

KW

|

4

|

||

|

|

Nm

|

22

|

||

|

Z-axis motor

|

|

aiF30-4000B

|

||

|

|

KW

|

7

|

||

|

|

Nm

|

30

|

||

|

Spindle motor

|

|

aiIP40-6000

|

||

|

|

KW

|

18.5/22

|

||

|

Feed

|

|

|

||

|

The X-axis is moving fast

|

m/min

|

20

|

||

|

The Z axis is moving fast

|

m/min

|

20

|

||

|

Rail width

|

mm

|

53

|

||

|

Precision

|

|

|

||

|

Positional accuracy

|

mm

|

0.008/0.008

|

||

|

Repeated positioning accuracy

|

mm

|

0.005/0.005

|

||

|

Hydraulic turret

|

|

|

||

|

Number of tool

|

#

|

12

|

||

|

Tool dimension

|

mm

|

□32/φ50

|

||

|

Others

|

|

|

||

|

Floor area

(length*width*height) |

mm

|

4100*3250*4500

|

||

|

Weight

|

kg

|

15500

|

||

Product Specifications

Standard configuration

1. Spindle unit:

High rigidity, high torque, high precision, easy to install and maintain.

2. Hydraulic tool holder:

Simple structure, strong rigidity, fast rotation.

3. The combination surface of the base and the column, slide board, spindle table, cutter tower, and each bearing seat are manually scraped to achieve maximum component accuracy, structural rigidity and load balancing.

4. The hydraulic station has the advantages of compact structure, convenient maintenance, high stability and low failure rate.

5. The fully covered protective sheet metal isolates the cutting iron chips from the coolant inside the machine, providing you with a safe and clean working environment.

6. The design of large bevel and ultra-wide chip discharge groove can easily leave the processing area through the chip flushing liquid belt to avoid high temperature cutting affecting the processing accuracy.

Motor power

Tool interference

Processing Capability

Similar Products

Hot Searches