The raw material is

crushed

to less than

20 mm

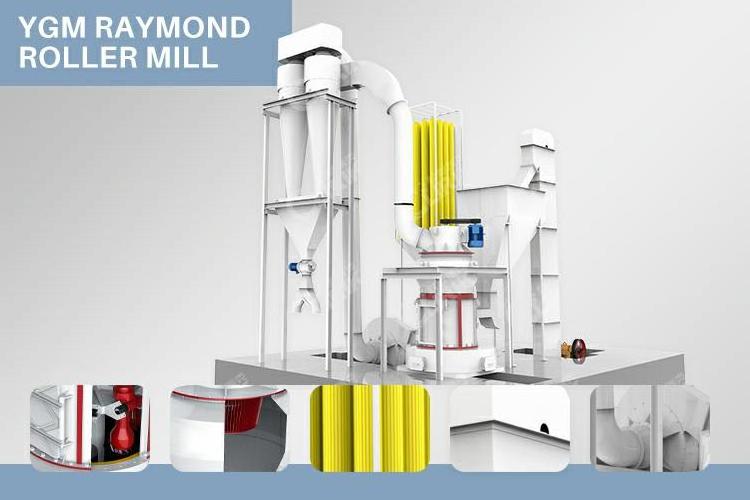

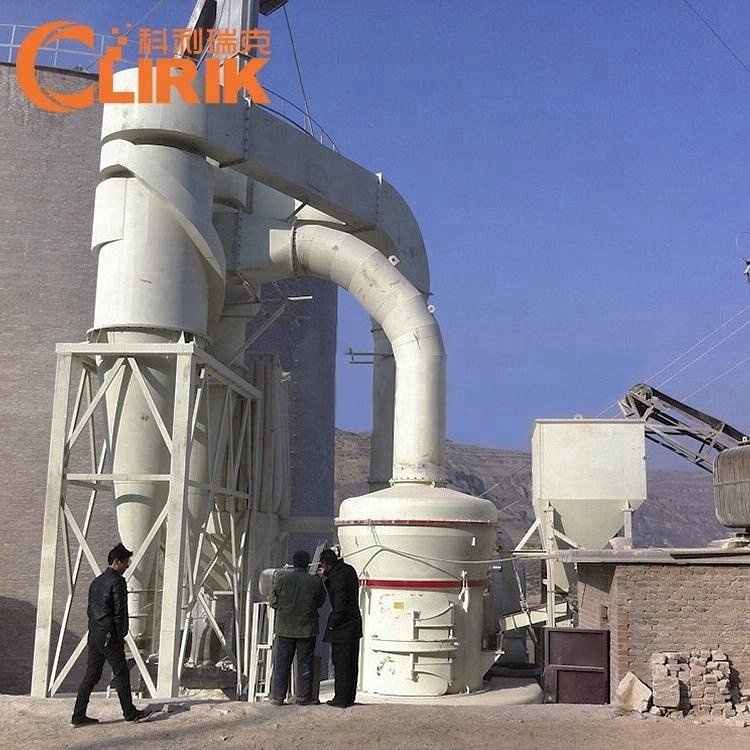

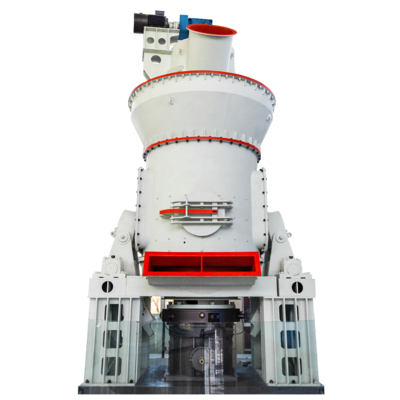

by the jaw crusher and then lifted to the storage hopper by the elevator. Then through the feeder, the raw materials are uniformly, quantitatively, and continuously sent to the main machine for grinding.

The ground powder is blown away by the airflow and separated by a classifier. The powder conforming to the fineness enters the cyclone collector through the pipe with the airflow and is separated and collected. Finally, the powder in the tube is discharged into finished powder.

The large cyclone collector is arranged at the upper end of the suction fan of the return duct, and the airflow of the whole system is a closed-loop, which flows and circulates under the state of positive and negative pressure.