NaN / 0

Full automatic gallon cap seal liner inserting machine plastic cap lid liner wad lining insertion machine

Get Latest Price

US$ 16000

≥1 Sets

Quick Details

Voltage:

220v or customize

Power:

0.5kw

Place of Origin:

China

Weight:

450 KG

Product Details

Product Description

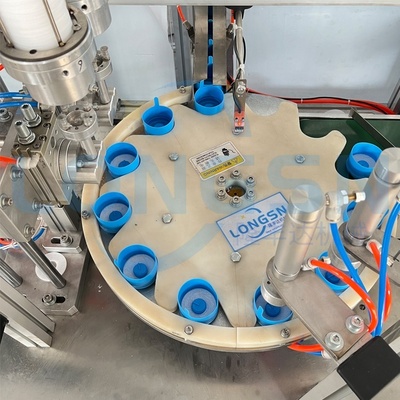

Full automatic gallon cap seal liner inserting machine plastic cap lid liner wad lining insertion machine

The automatic bottle cap lining/wadding machine can automatically insert the cap liner/wad/gasket into the plastic cap, avoiding manual pollution and greatly improving the production efficiency. It’s widely used in the pharmaceutical, daily chemical, food and beverage, health care products, mechanical or other industries.

Features:

1. Perfect Liner Sealing, Fast speed, High efficiency, Safe and Sanitary product.

2. This cap liner insertion machine replaces the handwork and can avoid secondary pollution for the occasion which has strict and severe sanitary requirements.

3. It adopts mechanical drive deliver position mechanism to make the machine operate smoothly. It is suitable for various specifications of bottle caps and liner/wad/gasket/foil.

4. With automatic counter function, convenient for statistics.

5. Rejection system for improperly stuffed caps or missing foil caps. (Optional: cooperate with visual inspection system to eliminate unqualified products)

6. It adopts PLC controller and has the advantages of free setting, wide application, easy operation, stable working, convenient maintenance, durable in use, etc.

It can be customized according to customer’s requirements, such as the cap lining machine with glue, it finishes the gluing before inserting the liner into cap.

Main Technical Parameters:

|

Cap Dia |

Productivity |

Voltage |

Power |

Dimension L×W×H |

N.W. |

|

30-80mm |

80-200 pcs/min. |

220 V |

0.5 KW |

2200×1200×1800(mm) |

450KGS |

Packaging & Shipping

Our Services

Before the order:

We will make detailed solution for you based on your requirments.

We will send you videos of our products to know more about our machines.

If you are willing to visit our factory,we will pick you up at a nearby airport/station.

After the order:

We will start to produce machines and update the progress.

Our engineer will draw the layout for you.

After-sales service:

Arrange our engineer to your factory to install machines if you need,train your employee until they can operate machines well.

Provide you 2 years warranty with spare parts 2 year free.

24 hours for engineer response (all services part 5days in customer hand by Intl' courier)

Hot Searches