NaN / 0

Overhead Gantry Crane 5 Ton 10 Ton Electric Hoist Harage Hantry Crane Single Girder Gantry Crane

Get Latest Price

US$ 8900

≥1 Sets

Quick Details

Rated Loading Capacity:

5-30 tons

Max. Lifting Height:

3~20M

Span:

8-30m

Application:

Outdoor;Workshop;Plant

Product Details

Product Description

Single girder gantry crane

is usually regarded as a light duty gantry crane due to its single beam structure design, which is mostly used in outdoor, open air and other environments that do not have the conditions of column driving beams. The main beam is supported by two outriggers, and a ground beam walking mechanism is arranged under it, which walks back and forth along the track.

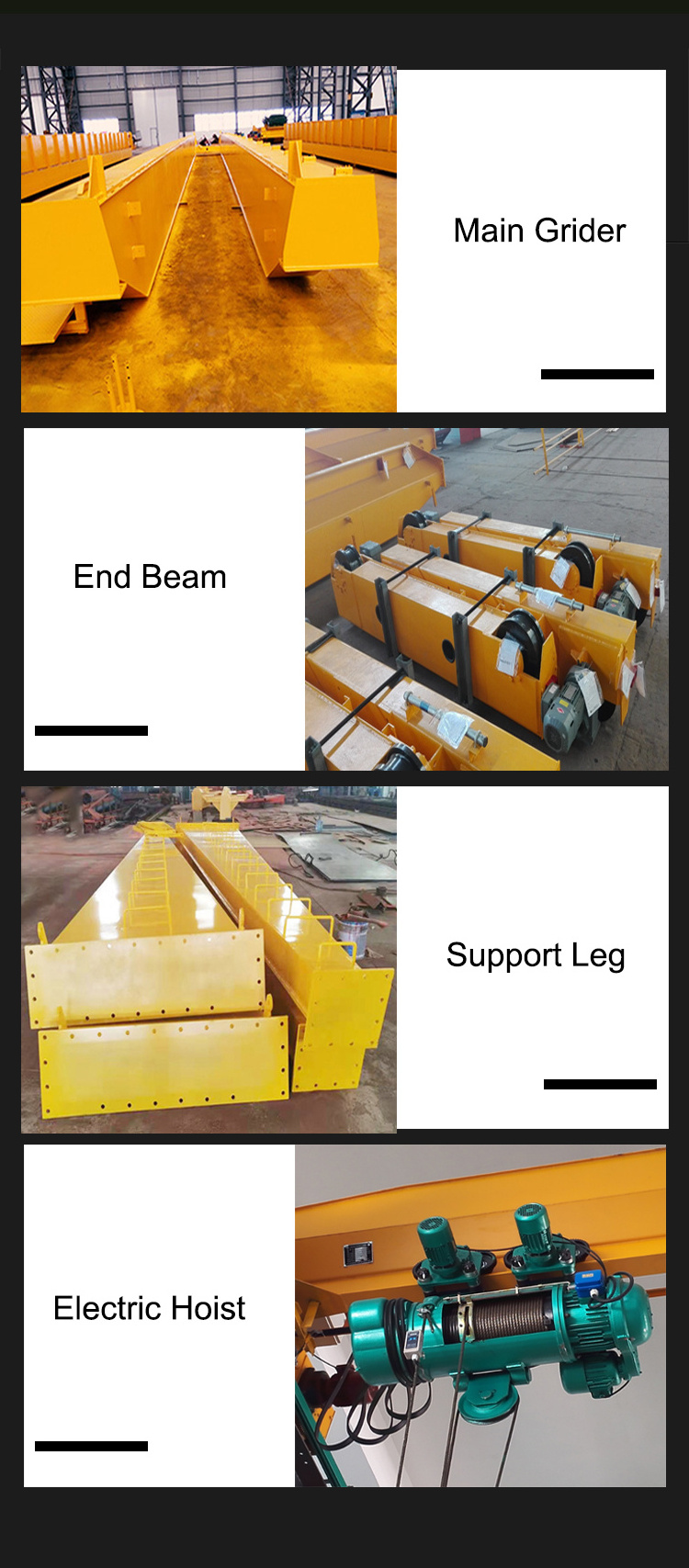

Details Images

Other Parts

Features Of Single Grider Gantry Crane

1. Cut Down your cost in building of plant and workshop;

2. Improve your production efficiency;

3. Be suitable for different operating conditions and provide you One-stop Solutions;

4. Reduce daily maintenance; 5. Safety with high performance.

Product View

Specification

|

Lift capacity

|

|

1ton ~ 32 tons

|

|

|

|||

|

Span

|

|

8~35m

|

|

|

|||

|

Lift height

|

|

6~18m

|

|

|

|||

|

Work duty

|

|

A3~A4

|

|

|

|||

|

Control method

|

|

Remote control or cabin control

|

|

|

|||

|

Lift speed

|

|

2~8M/Min

|

|

|

|||

|

Trolley Traveling Speed

|

|

2~20m/min

|

|

|

|||

|

Crane Traveling Speed

|

|

20m/min

|

|

|

|||

|

Power supply

|

|

220v/380v/400v/415v/440v/50hz/60hz/3p

|

|

|

|||

|

Working temperature

|

|

-20℃ ~ +40℃

|

|

|

|||

Production Process

Different Type Of Single Grider Gantry Crane

Exhibition

Packing & Delivery

1. Hoist and electric parts will be packed by plywood crate, for avoiding the demage from goods crash and impact during the delivery.

2. Girders and other main parts will be packed by plastic woven cloth, for preventing rust from soppy condition during the

transportation.

3. Only the best transport solution will be taken for saving your cost uttermost on finance, security and time.