NaN / 0

2022 Product Dismantled Motor Stator Cutting Machine Pulling Rotor Recycle Copper Scrap Electric Motor Recycling Machine

Get Latest Price

US$ 2999

≥1 Sets

US$ 1999

≥3 Sets

US$ 999

≥5 Sets

Quick Details

Place of Origin:

zhejiang

Brand Name:

BSGH

Weight (KG):

670

Marketing Type:

New Product 2022

Product Details

BSGH 3D Show Room Display

One stop recycling solution provider for scrap copper recycling machine from BSGH

This is our company's 3D real-world display, you can

click the picture to enter

, it contains other products of our company, and see if there are other products you need.

Product Description

BSGH motor recycling machine is your best choice!

We have more than 10 years experience,others company can't compete with us;

We have the most complete range of motor recycling machines;

Our market share in China reaches 70-80% ;BSM-40 is our latest product based on BSM-10 ,Others are still copying ours BSM-10;

Always imitated,never surpassed !

The best price and quality, trust worthy and choice!

How to recycle scrap copper winding wires from motor stators?

Do you want to know?

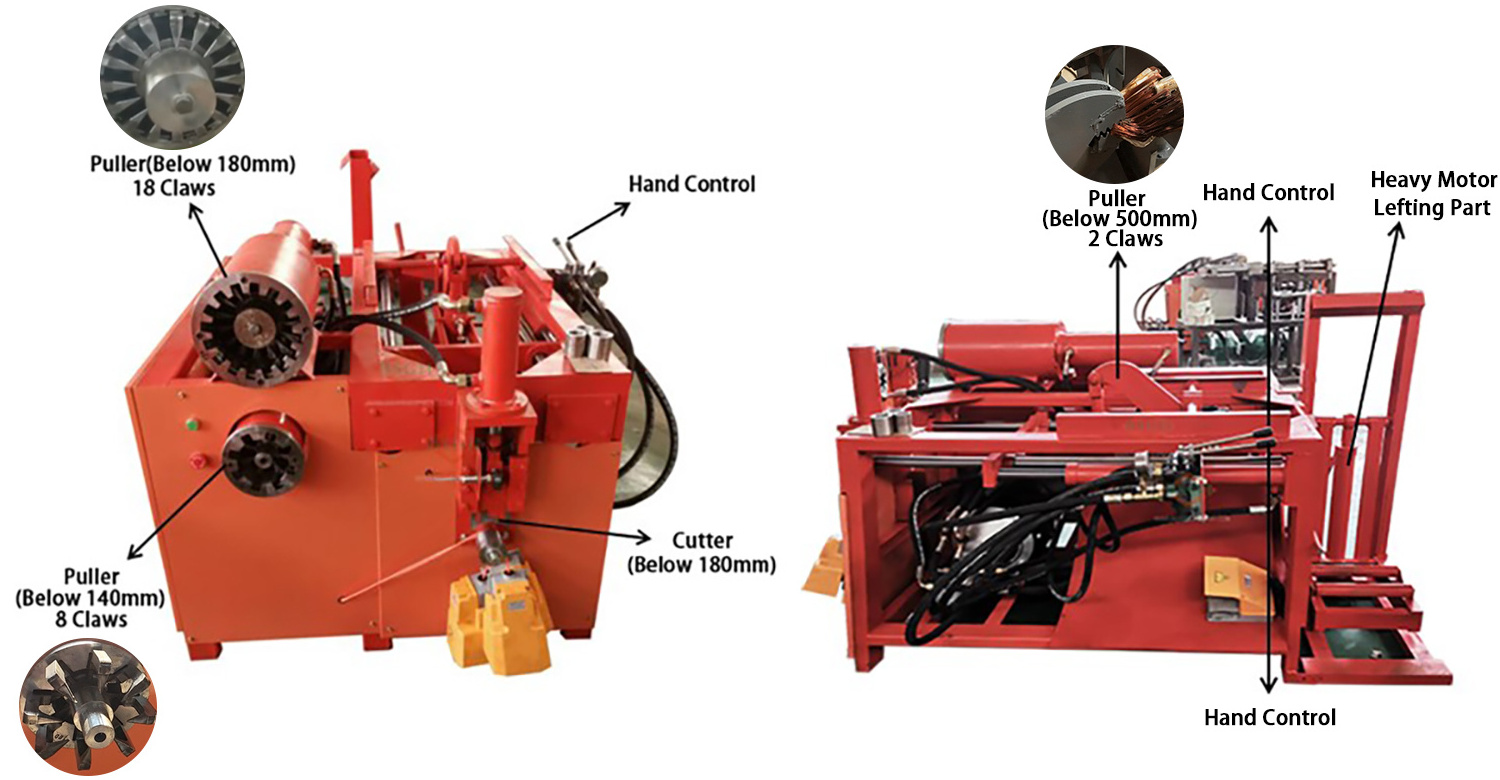

BSM-40 Motor Stator Rotor Cutting Machine

specialized to recover copper from scrap electric motors,

BSM-40 Motor Rotor Cutting Machine

not only can cut motor copper winding wire from one end but also can pull copper winding in 3 different parts.

BSM-40 Motor Stator Rotor Cutting Machine is our newly developed and improved machine with the most advanced double-cylinder design, more powerful and higher speed, BSM-40 Motor Stator Rotor Cutting Machine is a multi-functional copper recycling machine, specialized in recovering copper winding wires from scrap electric motor stators, integrating one cutting function and 3 pulling function and hydraulic clamp.

BSM-40 Motor Stator Rotor Cutting Machine is our newly developed and improved machine with the most advanced double-cylinder design, more powerful and higher speed, BSM-40 Motor Stator Rotor Cutting Machine is a multi-functional copper recycling machine, specialized in recovering copper winding wires from scrap electric motor stators, integrating one cutting function and 3 pulling function and hydraulic clamp.

Specification

|

Warranty

|

1 Year

|

|

Power

|

5.5KW

|

|

Marketing Type

|

New Product 2022

|

|

Weight (KG)

|

670kg

|

|

Model

|

BSM-40

|

|

Color

|

Customized Color

|

|

Usage

|

Recycle motor

|

|

Size

|

1940*1430*1150MM

|

|

Advantage

|

1cutting&3pulling

|

What better of BSM-40 Motor Stator Cutting Machine?

BSM-40 Motor Stator Rotor Cutting Machine has three pulling parts suitable for recycling copper from different diameters of the motor stator.

lf your motor stator is heavy and not easy to remove,BSM-40 Motor Stator Cutting Machine is useful to remove the motor stator to a suitable position by this listing part BSM-40 Motor Stator Rotor Cutting Machine has a wide processing range , can deal with waste motor stator diameter range in 50-500mm, such a useful machine for cutting and pulling copper motor.

How dose the machine works?

How to recycle scrap copper winding wires from motor stator?

Do you want to know?

First, you need to remove the motor shell for easy to recycle waste motor.

First, you need to remove the motor shell for easy to recycle waste motor.

Then, you can use this cutting part to cut the motor winding wires of the motor stator.

After motor cutting, choose a suitable pulling part to pull all the copper winding wires from the motor stator.

After motor cutting, choose a suitable pulling part to pull all the copper winding wires from the motor stator.

BSM-40 Motor Stator Cutting Machine

can deal with all kinds of motors,such as car motor,ceiling fan motor and others.

The final product as the picture,pure copper.

What does the machine‘s advantages?

1.

BSM-40 Motor Stator Rotor Cutting Machine

is BSGH newest multi-function motor dismantling machine, a kind of copper recycling machine,integrating cutting motor stator, copper winding wires pulling, and motor stator lifting platform;

2.Equipped with two air cylinders, machine working efficiency is higher and machine processing speed is faster than other motor recycling machines;

3.Equipped with China standard pure copper motor with strong power,more powerful and stronger than other machines;

4.Has the most advanced technology, the highest machine quality, and the best machine performance;

5.Has the lowest price, BSGH manufacturer factory direct sale;

3.Equipped with China standard pure copper motor with strong power,more powerful and stronger than other machines;

4.Has the most advanced technology, the highest machine quality, and the best machine performance;

5.Has the lowest price, BSGH manufacturer factory direct sale;

Packing & Delivery

Packing:

Inner:

BSM-40 Motor Stator Rotor Cutting Machine

covered bu plastic film;

Outer: BSM-40 Motor Stator Cutting Machine packed in 1*40HQ container.

Delivery: About 20-30 days after your payment.

Outer: BSM-40 Motor Stator Cutting Machine packed in 1*40HQ container.

Delivery: About 20-30 days after your payment.

Hot Searches