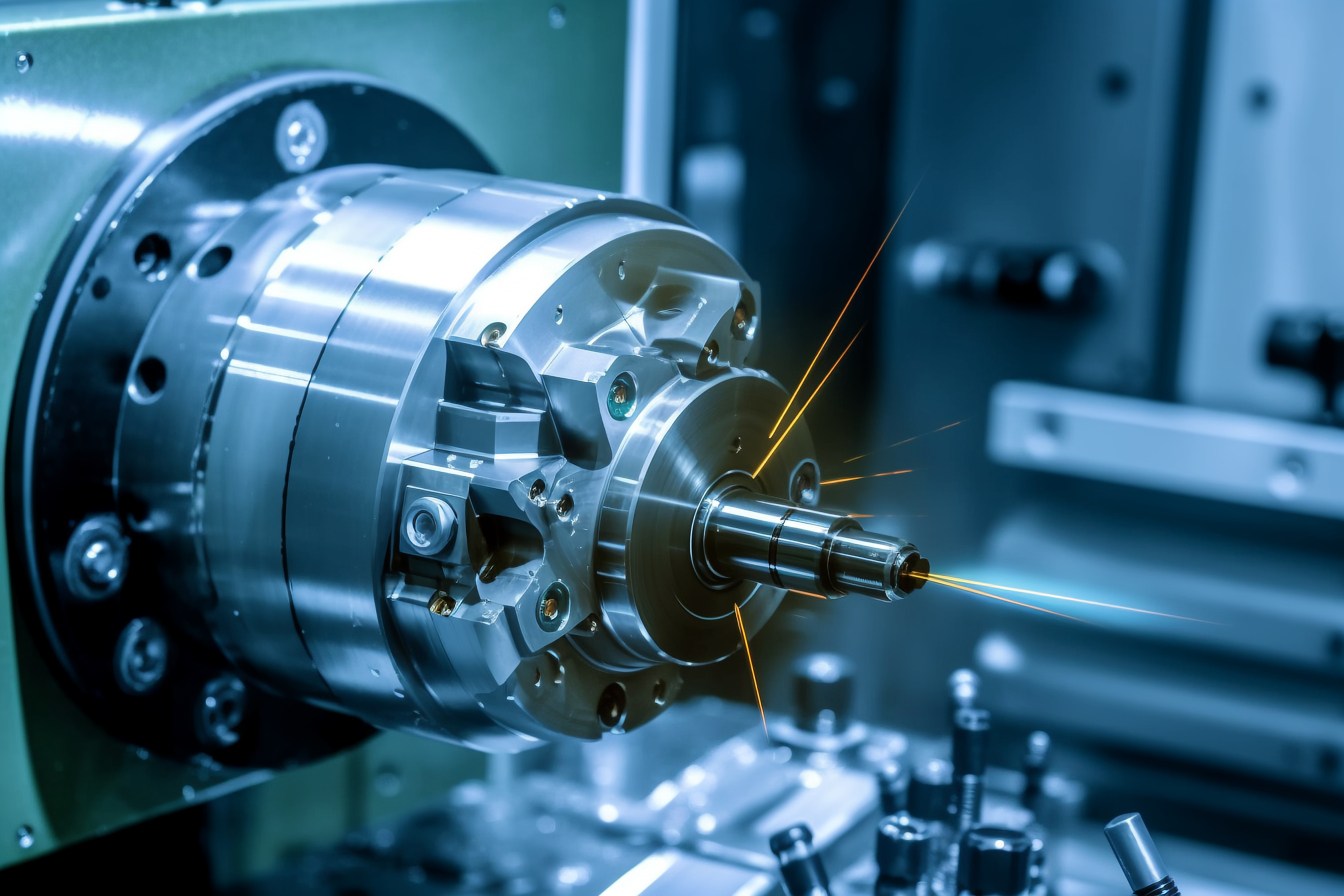

A Machining Process That Rotates a Workpiece While a Cutting Tool Removes Material from the Surface, Suitable for Cylindrical or Round-Shaped Parts Made of Various Materials Such as Metals, and Plastics, And Woods.

Advantages:

High Precision, Repeatability, And Efficiency in Mass Production.