NaN / 0

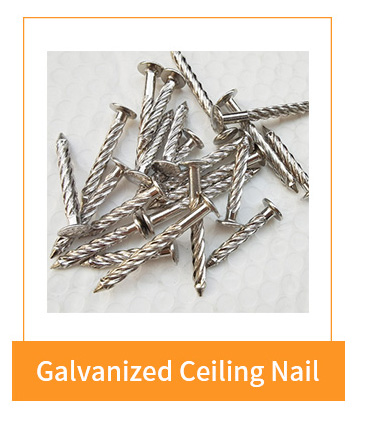

Rust-proof Umbrella Head Stainless Steel Brass Corrugated Galvanized Spiral Shank Roofing Nails

Get Latest Price

US$ 600 - 800

Min.Order: 1 Ton

Quick Details

Model NO:

NWN-RN002

Transport Package:

Carton

Origin:

Zhejiang China

Material:

Copper

Product Details

Umbrella Roofing Nail Description

Corrugated nails are mainly used for connecting wooden components, and fixing asbestos tiles and plastic tiles. If it is used on the roof, it is necessary to add wool felt gaskets to avoid rain leakage and nail cracking. Corrugated nails are almost always galvanized or aluminum. Galvanizing is adding a thin layer of steel or zinc to the top to hold it in place and keep it from rusting, and aluminum for the same reason. Corrugated nails should withstand years of rain, snow and other weather. Many corrugated nails have threads to aid in grip, are often installed in roofing materials, and help keep the nails from running out or loosening on the wood.

OEM & ODM

Bestsuppliers offers OEM and ODM service, with more 20 years of successful sourcing experience over the whole china we have already obtained a lot of suppliers resources in the sector of umbrella head roofing nails. All of our collaborative manufacturing partners are top selected factories with professional umbrella head roofing nails manufacturing experiences. If you have any special customization needs for umbrella head roofing nails products,please reach us by submitting the inquiry forms. We are here ready 24 hours to make your idea a value added product.

Umbrella Nail Production Process

1. Spheroidizing annealing:

Put the wire rod into the spheroidizing annealing furnace for spheroidizing annealing, heat it to 740°C-760°C with the furnace for three to five hours, and then cool it to 700°C-720°C for the second time Keep warm for two to four hours for the first time, then cool down with the furnace to 510°C-538°C, and then leave the furnace for air cooling;

2. Multiple drawing and reforming:

The wire rod after spheroidizing annealing is placed on a cold drawing machine for 4 to 7 times of drawing and reforming, and the size is reduced by 0.25mm-0.38mm after drawing;

3. Cutting the wire rod:

Put the wire rod after 4 to 7 times of drawing and restructuring into the cold heading machine, and cut the wire rod through the cutting mechanism on the cold heading machine;

4. One-time punching:

One end of the cut wire is inserted into the die hole, and the other end of the wire is protruded from the forming part and is punched once through a punching die;

5. Secondary punching:

The second punching die performs secondary punching on the other end of the wire after the first punching, so that the wire is punched to form a corrugated nail;

6. Tail tip forming:

Rub the corrugated nails formed by two punches through a thread rolling machine, so that the end of the corrugated nails away from the nail cap is rubbed to form a sharp part;

7. Galvanizing:

Put the rubbed corrugated nails into the galvanizing machine, and galvanize the corrugated nails to form the final product.

Brass Corrugated Nails Application

The corrugated nails are made of high-quality steel, which has good corrosion resistance. Due to its galvanized surface, its service life is greatly increased. The use of corrugated nails is one-time fixation. When using corrugated nails, fix things at one time, and don't worry about fixing them badly and pulling them out repeatedly. Therefore, it can be widely used in the following fields:

1. Chemical industry

2. Cars

3. Architecture

4. Furniture

5. Luggage

6. Toys, etc.

Product Category

Company Profile

If you are interested in our products,Please feel free to contact us!

FAQ

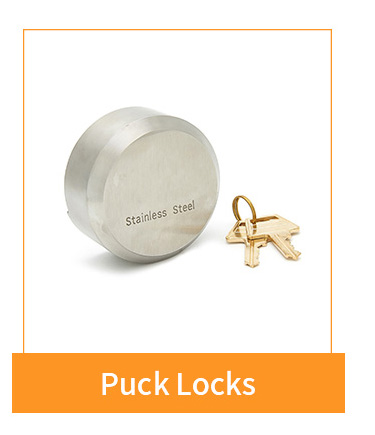

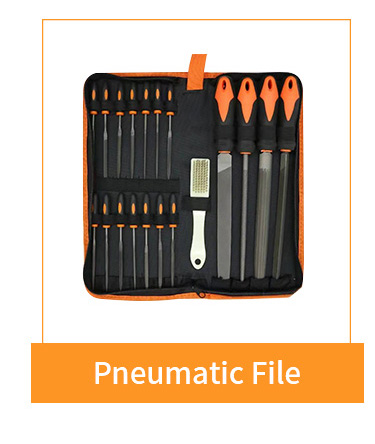

1.What types of hardware, tools, and locks do you supply?

Answer: We provide a diverse range of hardware and tools, including a variety of locks such as padlocks, door locks, and specialty locks. Our tools cover both hand tools and power tools for various applications.

2.Can I request product samples before placing a bulk order?

Answer: Yes, we encourage clients to request samples to evaluate the quality, durability, and functionality of our hardware, tools, and locks before committing to a larger order.

3.What is the minimum order quantity (MOQ) for your products?

Answer: The MOQ varies depending on the type of product. Please contact our sales team for specific information about MOQs for locks, tools, or other hardware.

4.How do you ensure the quality of your tools and hardware?

Answer: We implement stringent quality control measures at every stage of production to ensure that our locks and hardware meet the highest standards. Our team conducts thorough inspections and testing.