NaN / 0

HRC40-60 CBN Diamond Inserts CNGA120412-4N CBN Insert turning tools Brazed CBN Inserts

Get Latest Price

US$ 8.73

≥10 Pieces

US$ 8.5

≥100 Pieces

US$ 8.2

≥500 Pieces

Quick Details

Usage:

External Turning Tool

Hardness:

HRC40-60, HRC40-60

Coating:

TiNC or others

Place of Origin:

Hunan, China

Product Details

Products Description

|

We Are wholesaler

|

Factory wholesale price, OEM Service for you

|

|

Brand

|

Jinxin

|

|

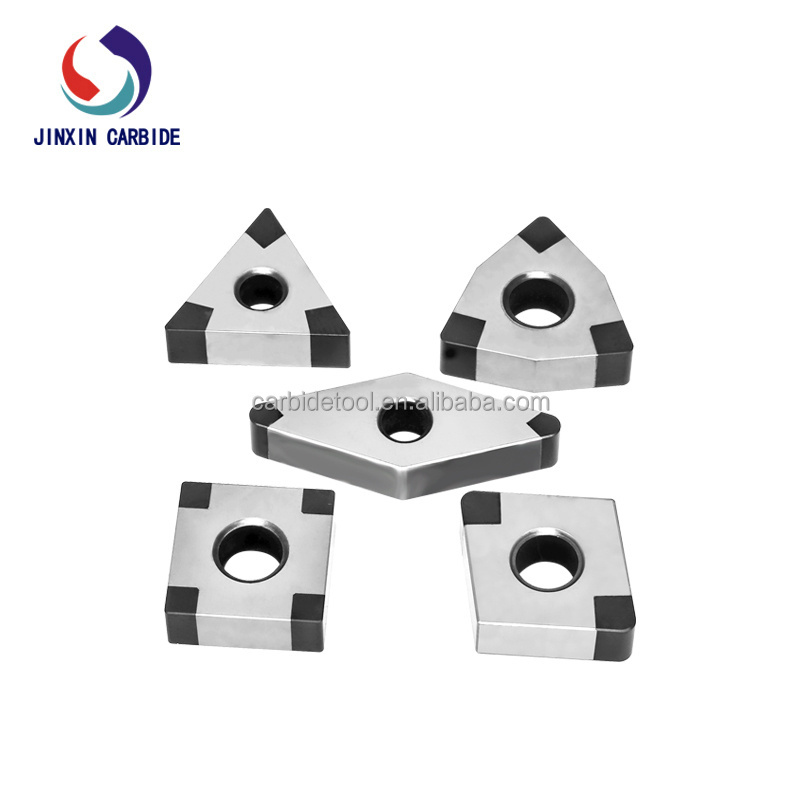

PCD & PCBN Inserts

|

DNGA TNGA CNGA WNGA SNGA VNGA

|

|

CBN Inserts

|

CNMG RMMN WNMN DNUN

|

|

Solid CBN Insert

|

WNMN DNUM RCMX RCMX

|

|

Solid CBN Brazed Insert

|

TNGA CNGA WNGA VNGA

|

|

HRC

|

HRA 48-80 hardness

|

|

Material

|

Cubid Boron Nitride

|

|

Suitable for

|

Roughing /Finishing/Semi-finishing

|

|

Customized

|

CBN Insert Material Characteristics:

1.The

hardness

of the CBN tool is second only to that of diamond, and it has excellent wear resistance, enabling high-speed machining with a long life.

2.The

high heat resistance

of CBN tools, materials that can still maintain stable physical properties at high temperatures, have high-speed, high-temperature cutting conditions.

3.The

good thermal conductivity

of the CBN tool can make the heat at the tip of the tool dissipate quickly, which is beneficial to the improvement of the machining accuracy of the workpiece.

4.The

lower friction coefficient

of CBN tool makes the cutting edge have excellent anti-adhesion ability, which is beneficial to the improvement of the quality of the machined surface.

For Advantage of our PCD CBN cutter

1) Hight Abrasion resistant/High impact resistance

2)Easy to replace inserts.

3)All the cutting tools quality meet the ISO international standard.

4)Use orginal tungsten carbide material as basement.Using content of 99.95% or more high purity raw material, to ensure

performance of PCD inserts basement.

5)Using box and carton packing, convenient for customer to handling.

1) Hight Abrasion resistant/High impact resistance

2)Easy to replace inserts.

3)All the cutting tools quality meet the ISO international standard.

4)Use orginal tungsten carbide material as basement.Using content of 99.95% or more high purity raw material, to ensure

performance of PCD inserts basement.

5)Using box and carton packing, convenient for customer to handling.

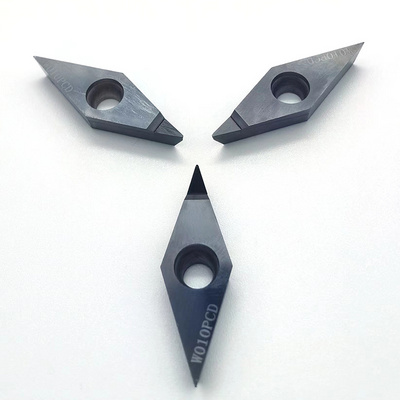

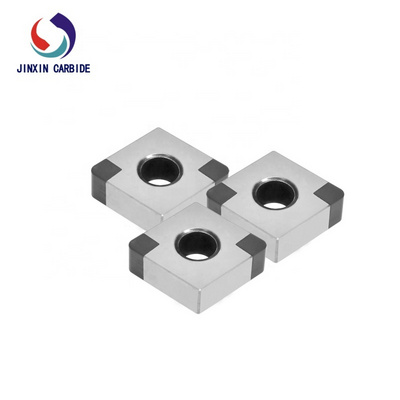

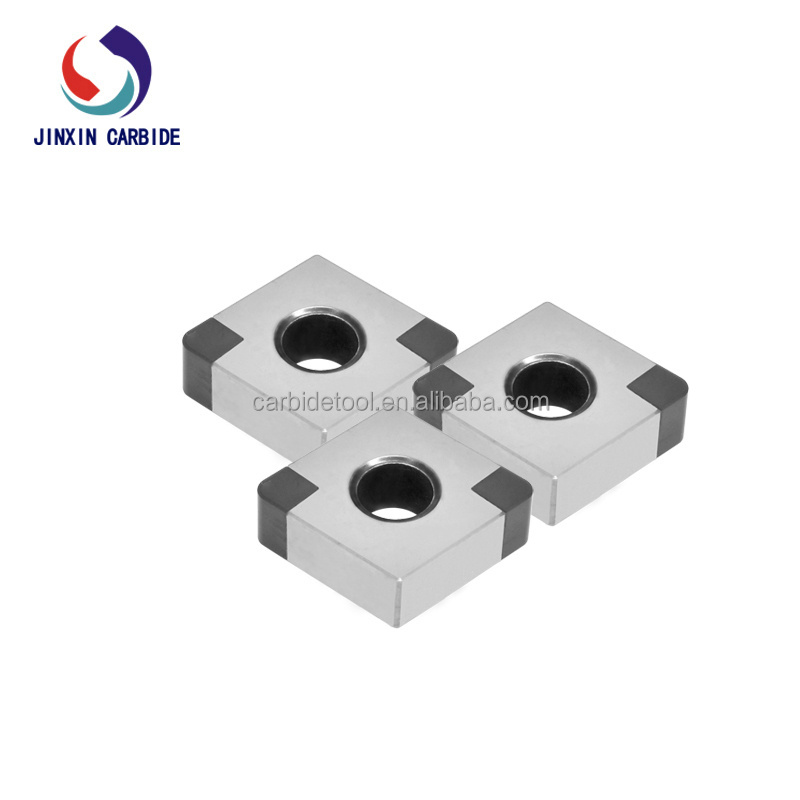

Product Show

CBN Milling Cutter

Custom CBN Insert

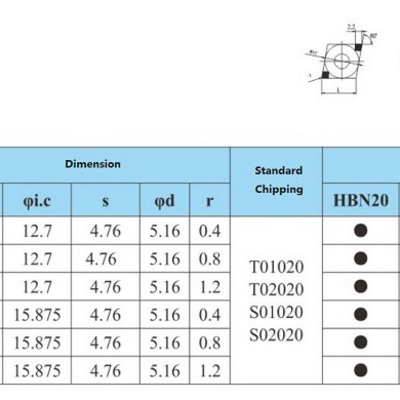

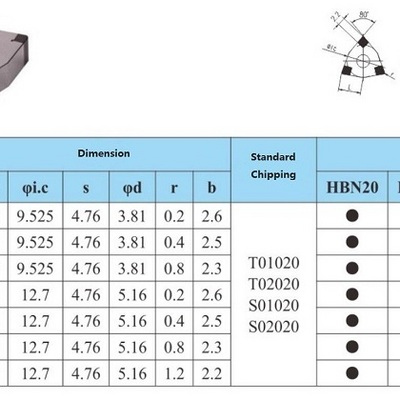

Product Paramenters

Application scenarios

For turning and milling of cylinder blocks and heads, centrifugal rolls, slurry pumps, brake discs, brake drums, rolling mortar walls, compressor parts, gears, bearings, mining machinery, coal mining machinery industries

Hot-sale products

Main Products

Packaging & shipping

Q: Are you trading company or manufacturer ?

A: We are manufacturer of tungsten carbide since 2009. We can supply 20 tons tungsten carbide product per month. We can provide customized carbide products as per your requirements.

Q: How long is your delivery time?

A: Generally,it will take 7 to 25 days after order confirm.The specific delivery time depends on the specific product and the quantity you needed.

Q: Do you provide samples? iIs it free or charged?

A:Yes, we can offer a sample for free charge but the freight is at customers’ cost.

Q. Do you test all your goods before delivery?

A: Yes, we will do 100% test on our cemented carbide products before delivery.

A: We are manufacturer of tungsten carbide since 2009. We can supply 20 tons tungsten carbide product per month. We can provide customized carbide products as per your requirements.

Q: How long is your delivery time?

A: Generally,it will take 7 to 25 days after order confirm.The specific delivery time depends on the specific product and the quantity you needed.

Q: Do you provide samples? iIs it free or charged?

A:Yes, we can offer a sample for free charge but the freight is at customers’ cost.

Q. Do you test all your goods before delivery?

A: Yes, we will do 100% test on our cemented carbide products before delivery.