NaN / 0

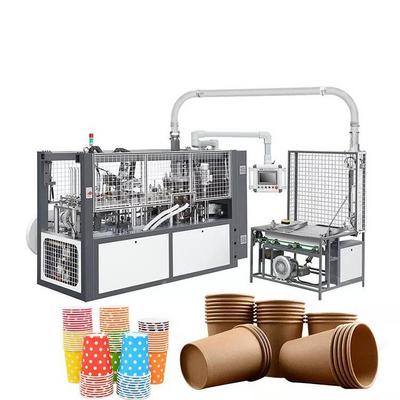

Fully - automatic disposable plastic plates cups lid making machine

Get Latest Price

US$ 19000

≥1 Sets

Quick Details

Place of Origin:

Zhejiang, China

Brand name:

WENZHOU JAICHENG MACHINERY CO., LTD

Suitable material:

PVC PET PS

Max Forming Area:

470x225mm

Product Details

Automatic cup cover forming machine

Product introduction

JC-500 series Automatic Blow Molding and plastic sucking lids forming machine are developed by our research and development personnel according to packing market requirement. In combination with the advantages of aluminum-plastic blister packing machine and plastic sucking forming machine, this machine is a new type of product developed in light of pharmaceutical standard GMP and food standard QS . This machine adopts a fully automatic flow covering blow molding or plastic suction molding, punching and diet cutting ac the special properties of product required by the users. It is with advanced technology, safe and simple operation , which will avoid the consumption of labor on the manual punching and contamination from the touch with the employee. Therefore, the quality requirement, and it enjoys low power consumption, small covering of land.

Technical Data JC-500 series

|

Model |

JC-500B |

JC-500C |

|

Punch speed |

15-35(times/min) |

15-35(times/min) |

|

Max. Forming area |

470*225mm |

470*290mm |

|

Max. Forming depth |

47mm |

47mm |

|

Stroke |

60-230mm |

60-300mm |

|

Material |

PVC PET PS |

PVC PET PS |

|

Total power |

10.5kW(380V) |

11.5kW(380V) |

|

Compressed air |

0.6-0.8Mpa |

0.6-0.8Mpa |

|

Mold Cooling |

60 L/H tap water / recycle water |

60 L/H tap water / recycle water |

|

Overall dimension |

3500*1000*1800mm |

3500*1000*1800mm |

|

Weight |

2300KG |

2400KG |

Features

1.Speed reducer, main-rotating connection, main shaft are on line (to decrease driving error)for mechanical transmission.

2.Sensor controls are adopted in pneumatic system. PLC control makes the whole machine run smoothly, keeps synchronous stability during the products are t be packed in multi-labor, long-distance.

3.Main motor variable frequently speed regulating, the travel adjustable at will, simple and convenient to change the mould, cam traction, stable running.

4.Positive pressure formation in the equipment(Puffing forming)

Detailed Images

A PART OF SAMPLE

Hot Searches