NaN / 0

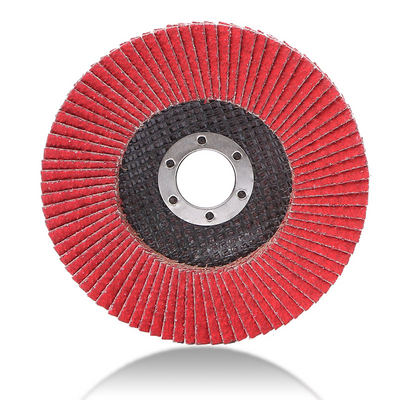

XMGT non woven polishing wheel angle grinder 100*19mm abrasive sanding flap disc grinding wheels for wood metal stainless steel

Get Latest Price

US$ 3.38

≥100 Pieces

US$ 2.38

≥5000 Pieces

Quick Details

Type:

Flap Wheels

Place of Origin:

China

Brand Name:

XMGT

Model Number:

cylinder flap wheel

Product Details

Product Description

Features:

Non-woven polishing abrasive flap wheel and brush wheel

Generates uniform distinct satin and antique finishes

Dense, very durable web means these wheels can be used for blending applications,Nonwoven and Interleaved Flap Wheels for electronic product manufacture.

Applications:

Light deburring and cleaning parts of irregular shape, pipes or moulded parts. Satin finishing small surfaces. Removing scale. Removing marks left by previous operations and re-finishing after bending, welding or satin coil moulding.

Nonwoven and Interleaved Flap Wheels for electronic product manufacture.

|

Diameter of the wheel:

|

50,100,150,200,250,300mm

|

|

|

|

All sizes

and colors can be customized

|

||||

|

Thickness:

|

20,25,50,60,80,100,115mm

|

|

|

|

|

||||

|

Color:

|

yellow, brown, etc

|

|

|

|

|

||||

|

Grit:

|

40#~600#

|

|

|

|

|

||||

|

Different bore:

|

32,19,16mm

|

|

|

|

|

||||

|

Hardness:

|

Soft, Medium, Hard, Very hard

|

|

|

|

|

||||

Usage

Suitable for buffing, polishing and ginding metal, jewellry, etc

Used widely in aerospace, plant maintenance, foundry, automotive, metal fabrication and shipyards

Product Advantages

1.Easy application and removal.

2.High efficiency.

3.Safe,efficient,low consumption.

4.Resist moisture and heat.

Characteristics:

(1). Cool running

(2). High stock removal

(3). Non-loading consistent finish

(4). Availabel diameters from P24 to P400

(5). Available grain: Ceramic , Aluminium oxide, Silicon carbide, Zirconia.

(6). Available Backing: Fiber glass backing , nylon backing , plastic backing .

Shipping

Company Introduction

Established in 2003, Xiamen Globe Truth (GT) Industries Co., Ltd. has developed into an international manufacturing and trading group, supplying a wide range of stone tools, such as blades, diamond saw blades, cutting blades,blank, diamond core drills , diamond segments, polishing pads, diamond turbo cup grinding wheels, wire ropes, profile wheels, abrasive brushes,ect , one stop-shopping is our feature, providing customers with the most convenience.

Insist on Maintaining high quality concept and implementing quality management procedures throughout our entire production process, we manufacture our products in accordance with international standards.

Our company believes that "good service is the key to good relationships with clients". We strive to maintain high quality standards, offer competitive prices and ensure prompt delivery. In this way, our products have continued to gain market acceptance and customer satisfaction. If you are interested in any of our products, please do not hesitate to contact us with your detailed inquiries .

Insist on Maintaining high quality concept and implementing quality management procedures throughout our entire production process, we manufacture our products in accordance with international standards.

Our company believes that "good service is the key to good relationships with clients". We strive to maintain high quality standards, offer competitive prices and ensure prompt delivery. In this way, our products have continued to gain market acceptance and customer satisfaction. If you are interested in any of our products, please do not hesitate to contact us with your detailed inquiries .

FAQ

1. You are a trader or a manufacture?

We are an industry and trade integration business

2. How can I chooice the right prioduct ?

Give us correct size and grit request . All detail will be confirmed before production .

3. How about the payment terms?

We usually accept T/T ,Western union or L/C. other terms also could be negotiated.

4. What is your minimum order?

It depends on what you are buying. Normally, our minimum order is 100pieces .

5. What is your delivery time?

FOB Xiamen or any Chinese port : 15 days . If there are any parts in stock , our delivery time is only 3-7days.

6. What about Quality Control?

We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.

|

COLD PRESS SINTERED SEGMENTED

|

|

|

|

|

|

|||||

|

Application: For cutting granite, marble, concrete and various of construction materials.

|

|

|

|

|

|

|||||

|

|

OUTER DIAMETER

|

|

BORE

|

SEGMENT

|

SEGMENT

|

|||||

|

|

MM

|

INCH

|

DIAMETER(MM)

|

WIDTH(MM)

|

HEIGHT(MM)

|

|||||

|

GTDB105

|

105

|

4’’

|

22.23/20/16

|

2.0

|

7/10

|

|||||

|

GTDB110

|

110

|

4.3’’

|

22.23/20/16

|

2.0

|

7/10

|

|||||

|

GTDB115

|

115

|

4.5’’

|

22.23

|

2.0

|

7/10

|

|||||

|

GTDB125

|

125

|

5’’

|

22.23

|

2.2

|

7/10

|

|||||

|

GTDB150

|

150

|

6’’

|

22.23

|

2.2

|

7/10

|

|||||

|

GTDB180

|

180

|

7’’

|

22.23/25.4

|

2.4

|

7/10

|

|||||

|

GTDB200

|

200

|

8’’

|

22.23

|

2.4

|

7/10

|

|||||

|

GTDB230

|

230

|

9’’

|

22.23

|

2.6

|

7/10

|

|||||

|

GTDB250

|

250

|

10’’

|

25.4/22.23/20

|

2.6

|

7/10

|

|||||

|

GTDB300

|

300

|

12’’

|

27/25.4/22.23/20

|

3.0

|

7/10

|

|||||

|

GTDB350

|

350

|

14’’

|

27/25.4/22.23/20

|

3.0

|

7/10

|

|||||

|

Difference arbor size and segment specifications are available upon request.

|

|

|

|

|

|

|||||

Blister packing with color paper

Color boxes packing

Double blister packing with color paper

All goods put into seaworth carton

Established in 2003, Xiamen Globe Truth (GT) Industries Co., Ltd. has developed into an international manufacturing and trading group, supplying a wide range of stone tools, such as blades, diamond saw blades, cutting blades,blank, diamond core drills ,diamond segments, polishing pads, diamond turbo cup grinding wheels, wire ropes, profile wheels, abrasive brushes,ect , one stop-shopping is our feature, providing customers with the most convenience.

Insist on Maintaining high quality concept and implementing quality management procedures throughout our entire production process, we manufacture our products in accordance with international standards.

Our company believes that "good service is the key to good relationships with clients". We strive to maintain high quality

standards, offer competitive prices and ensure prompt delivery. In this way, our products have continued to gain market acceptance and customer satisfaction. If you are interested in any of our products, please do not hesitate to contact us with your detailed inquiries.

Our company believes that "good service is the key to good relationships with clients". We strive to maintain high quality

standards, offer competitive prices and ensure prompt delivery. In this way, our products have continued to gain market acceptance and customer satisfaction. If you are interested in any of our products, please do not hesitate to contact us with your detailed inquiries.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally 25-30 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=5000USD, 100% in advance. Payment>=5000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

A: We are factory.

Q: How long is your delivery time?

A: Generally 25-30 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=5000USD, 100% in advance. Payment>=5000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Hot Searches