NaN / 0

5mm 3pin Dual Color Yellow & Green Yellow Common Cathode Round Diffused Lens with Flange 5mm LED Diode Lamp Bead for indicator

Get Latest Price

US$ 0.01

≥1000 Pieces

Quick Details

Model Number:

DM-38226CC-05YGy-BML60-D

Brand Name:

Demo

Mounting Type:

through hole

Description:

common cathode

Product Details

Product Description

5mm 3pin Dual Color Yellow Green Common Cathode Round Diffused Lens with Flange 5mm LED Diode for Indicator

Product details

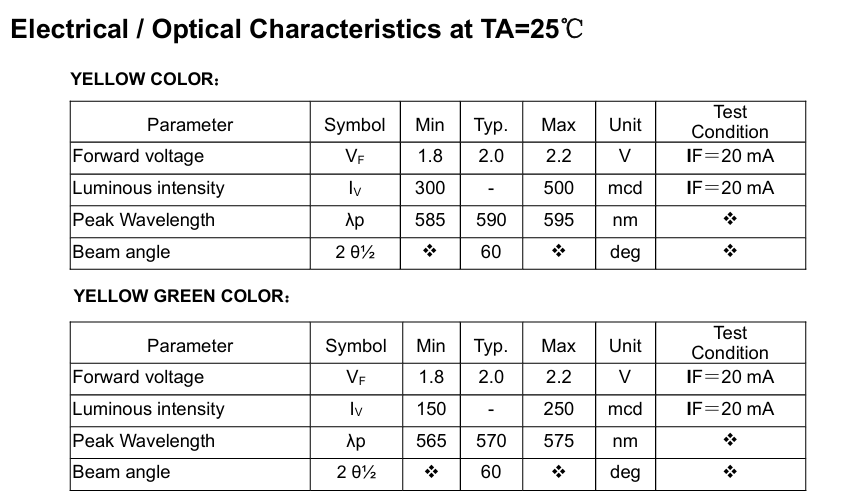

| Color mixing | yellow/green yellow |

| Size | 5mm |

| Shape | round head with flange |

| Lens | diffused lens |

| Voltage | 1.8-2.2V |

| Type | common cathode |

| Beam Angle | 60deg |

| Peak Wavelength | yellow:585-595nm ; yellow green:565-575nm |

| Luminous Intensity | yellow:300-500mcd; yellow green:150-250mcd |

Dimension:

The First Choice in LED Customized Manufacturing!

LED Manufacturer with 10+ years Experience!

High-Quality Long Lifespan LED!

Our Service

1)Customized View angles are acceptable! 10deg, 15deg, 30deg, 45deg, 60deg, 90deg, 120deg, 160deg , etc. for options!

2)Customized LED shapes for options, round head shape, bullet head shape, flat head shape, rectangle shape, oval shape, concave shape, straw-hat shape, etc.

3)Various LED size for options, 2mm/3mm/4mm/5mm/8mm/10mm

Notice for LED Handling

1)All personnel in direct contact with the LEDs throughout the process of use shall perform anti ESD measures. Do not touch the LEDs directly with hands

2) When welding, the operator needs to pay attention to the welding time, welding temperature, and the positive and negative poles of LEDs should be clearly distinguished.

3) Electrical parameters such as current and voltage should not exceed the rated value.

Precautions for LED Soldering

1)The welding time should not exceed 3 seconds

2)The welding temperature is less than 260 ℃

3)Reflow welding is allowed only once

4)When welding, distinguish the positive and negative poles and avoid the lens to avoid damaging the lens.

5)When welding, distinguish the positive and negative poles of LEDs, take care to avoid touching the LED lens from lens-damaging.

6)Especially for IR LEDs and UV LEDs, try to take cooling measures as good as possible to provide adequate heat dissipation area.

7)For longer life of IR LEDs and UV LEDs, it is recommended to use a more stable constant current driver instead of a constant voltage driver.

Hot Searches