NaN / 0

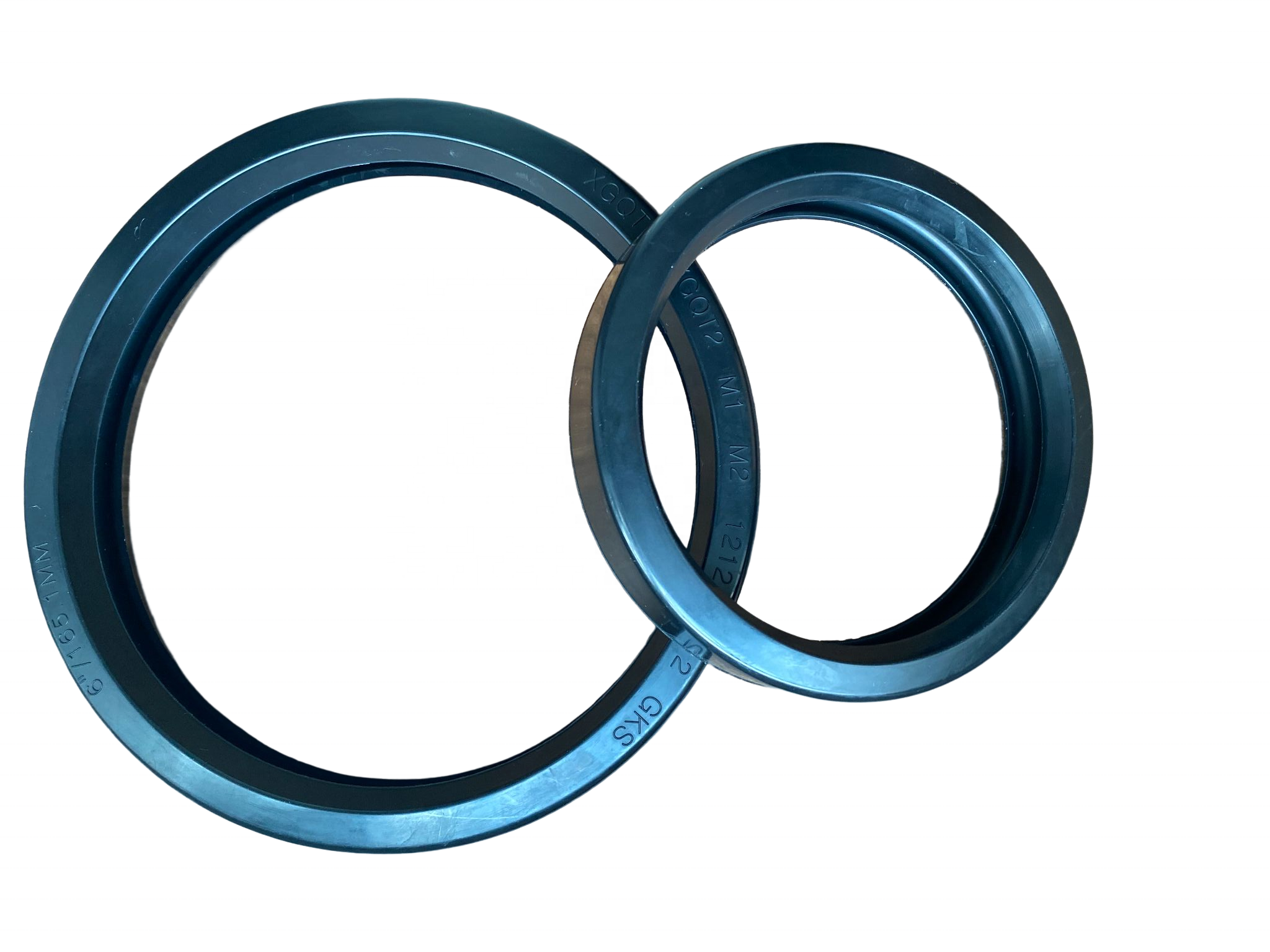

High quality waterproof Rubber Seal Products Rubber Gasket Seals EPDM material

Get Latest Price

US$ 0.2

≥1000 Pieces

Quick Details

Processing Service:

Moulding

Place of Origin:

Shandong, China

Brand Name:

ZDSY

Model Number:

33-610, Customized

Product Details

Product Description

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

ZDSY

|

|

Product Name

|

Flexible Grooved Pipe Fittings Sealing Ring

|

|

Size

|

33-610

|

|

Color

|

Black or Customized

|

Product Paramenters

How to Select Rubber Materials for Seals

In the selection of rubber materials for seals, we must consider several important indicators:

I.Consideration of use conditions

1.Objects to be touched (including liquid, gas, solid and various chemical agents)

2.Range of Temperature (lowest and highest temperature)

3.Range of Pressure (Minimum compression ratio of seals under pressure)

4.Static or dynamic using considerations

II.Consideration of design requirements

1.Combination of consideration

2.Consideration of possible chemical reactions in use

3.Consideration of service life and review of possible failure cause

4.Consideration of component lubrication and assembly method

5.Consideration of tolerance

III. Consideration of inspection requirements

1. Define inspection criteria

2. Determine confirmation of the need for sample

3. Set the acceptable criteria

4. Main sealing surface setting

IV. Selection of material specifications

1. Determine the selection of material specifications, such as ASTM, DIN, JIS, etc.

2. Discuss with suppliers. Define the selection of rubber materials.

3. Choose the supplier with good quality and maintain stability of the supplier.

V. Cost considerations

Choose suitable materials, in order to avoid improper rubber materials with high cost, resulting that the products can not play the sealing function. Both natural and synthetic rubbers have common rubber properties, such as resilience after compression, flexure resistance, compression resistance and permeability to gas and liquids.

Each type of rubber elastomer has its own unique properties. At the same time, the rubber composition can also affect its properties. At present, there are more than 20 kinds of rubber elastomers and they are widely used in all kinds of material needs. In addition, through the professional mixing refinery formula design and mixing, it can provide more in line with the needs of various projects. At the same time, vulcanization transforms rubber from a thermoplastic mixture into a thermosetting shape. Crosslink provides rubber molecular chain strength and elasticity to the performance of seals. Therefore, it is very important for the seal designer to discuss with the sealant builder and the sealant supplier about the materials to be used.

|

Types & Codes of Rubber

|

|

|

|

|||

|

Chinese Name

|

English Name

|

Code Names

|

ASTM Code

|

|||

|

天然橡胶

|

Natutal Rubber

|

NR

|

AA

|

|||

|

异戊橡胶

|

Poly isoprene Rubber

|

IR

|

AA

|

|||

|

丁苯胶

|

Styrene butadiene Rubber

|

SBR

|

AA

|

|||

|

顺丁胶

|

Polybutadiene Rubber

|

BR

|

AA BA

|

|||

|

丁基橡胶

|

Butyl Rubber

|

HR

|

BA

|

|||

|

乙丙胶

|

Ethylene propylene Rubber

|

EPDM

|

AA BA CA DA

|

|||

|

氯丁胶

|

Polychliroprene Rubber

|

CR

|

BC BE

|

|||

|

丁腊胶

|

Nitrile Rubber

|

NBR

|

BF BG BK CH

|

|||

|

聚氨酯胶

|

Polyurethane Rubber

|

PU

|

BG

|

|||

|

氯磺化聚乙烯胶

|

Hypalon. Polyethylene

|

CSM

|

CE

|

|||

|

丙烯酸酯橡胶

|

Polyacrylate Rubber

|

ACM

|

DF DH EH

|

|||

|

氯醇橡胶

|

Epichlorohydrin Rubber

|

ECO

|

CE

|

|||

|

乙烯-丙烯酸胶

|

VamacfEthylene/Acrylic) Rubber

|

E/A

|

EE

|

|||

|

硅橡胶

|

Silicone Rubber

|

SI

|

FC FE GE

|

|||

|

氟素橡胶

|

Fluoro Carbon Rubber

|

FPM

|

HK

|

|||

|

氢化丁腈橡胶

|

Hydrogenated Nitrile Rubber

|

HNBR

|

DH

|

|||

|

氟素硅胶

|

Fluorinated Silicone Rubber

|

FLS

|

FK

|

|||

|

Working Conditions of Rubber Materials

|

|

|

|

|

|

|||||

|

Group of Rubber

|

Range of Hardness (Shore Type A)

|

Properties of Rubber

|

Working Pressure

MPa |

Working Temperature

(°C) |

Working Medium

|

|||||

|

I -1

|

HS65±5° A

|

Oil Resistance

|

<8

|

-35〜+100

|

Mineral Oil, Air, Water

|

|||||

|

I -2

|

HS75±5° A

|

|

<16

|

-30〜+100

|

Mineral Oil, Air, Water

|

|||||

|

I—3

|

|

Oil Resistance &Low Temperature Resistance

|

<16

|

-40〜+100

|

|

|||||

|

I -4

|

HS85±5° A

|

Oil Resistance

|

<32

|

-25〜+100

|

|

|||||

|

II-1

|

HS65±5° A

|

Oil Resistance &High Temperature Resistance

|

<2.

|

-20〜+220

|

|

|||||

|

II-2

|

HS75±5° A

|

|

<16

|

|

|

|||||

|

III-1

|

HS65±5° A

|

Acid and Alkali Resistance

|

<2

|

-25〜+80

|

20% Sulfuric Acid 20% Salt

|

|||||

|

III-2

|

HS75±5° A

|

|

<2.

|

-25〜+80

|

20%Na0H

|

|||||

|

III-3

|

HS85±5° A

|

|

|

|

20% Potassium Hydroxide

|

|||||

Note:

This standard specifies the classification and requirements of rubber materials for day motion sealing belts on the financial emergency system when oil based hydraulic oil and lubricating oil are used.

【1】

The material of each compound is not specified clearly. Group I can be nitrile butadiene rubber;Group II can be fluoro rubber;Group III can be natural rubber or choose appropriate materials; Example: Ethylene Propylene Rubber (EPR, EPDM), neoprene rubber, butyl rubber, etc.

【2】

The Shaw Type A in the rubber industry, polyurethane industry and plastic industry in our country refers to that its hardness is same. The rubber materials of reciprocating motion sealing ring specified in this standard are divided into A and B categories. Type A is the nitrile rubber material and Type B is the castable polyurethane rubber material. Type A is butyl wax rubber material, type B is cast polyurethane rubber material.

Production Equipments

Inspection Equipments

Hot Searches