NaN / 0

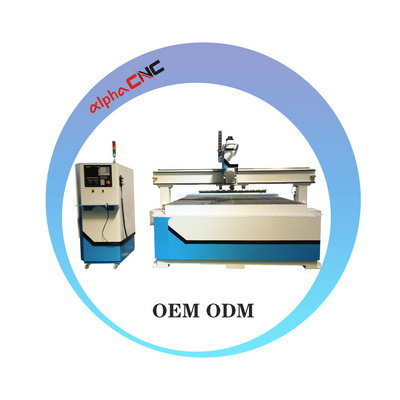

Desktop woodworking machine Mini automatic tool changer 6090 CNC wood router

Get Latest Price

US$ 5500

≥1 Sets

US$ 5200

≥2 Sets

US$ 5000

≥10 Sets

Quick Details

Working Table Size(mm):

600×900

Machine Type:

CNC Router

Range of Spindle Speed(r.p.m):

6000 - 24000 rpm

Positioning Accuracy (mm):

0.1 mm

Product Details

Product Advantages

Automatic tool change 6090 CNC router

Advantages:

QUICK CNC bench top CNC router is a small cnc router ideal for prototyping and smaller production runs. It features a work envelope of 24″ x 36″ and includes an industrial-grade, liquid-cooled electrospindle. Despite its smaller footprint, it has the same accuracy and cut quality of much larger CNC machines and woodworking routers.

Features:

1. Ruggedly constructed machine structure. Material is Stress relieved and annealed for deformation free,thus always keep machine accurate.

2. Machine base is produced by CNC machine, and machine base’s five sides are produced at one same procession to make sure the machine body geometry tolerance is standard.

3. The unique reality of the 3-axis screw, the machining accuracy is more accurate.

4. The router spindle is very high precision and water-cooled. which keeps the spindle at a constant temperature and maintains longevity.

Machine Parts

Machine parts of automatic tool change 6090 CNC router

1. 2.2kw water cooling spindle HQD

2. Dust hood for spindle

3. 2.2kw Delta inverter

4. Ball screw on all axis

5. Linear Guide way 15mm

6. Stepper Motor

7. Machine body design

8. Router Bit

9. MDF T slot table

10. Position of stop switches

11. controller Model: DSP B57

Product Parameters

|

Product name |

K6090T |

|

XYZ axis working area |

600 x 900x 150mm |

|

Machine Size |

720x 1135mm |

|

Y axis rail |

15mm square |

|

Ball screw |

Taiwan TBI ball screw |

|

Max. Speed |

8m / min |

|

Max. Cutting speed |

5m / min |

|

Spindle power |

2.2kw water cooling |

|

Spindle speed |

6,000 – 24,000 RPM |

|

Inverter power |

2.2kw Delta |

|

Drive motors |

Stepper Motor |

|

Control system |

DSP A11 |

|

Working voltage |

AC220V / 50-60Hz, 1-phase |

|

Table |

PVC T slot |

|

Control type |

Handheld |

|

Packing dimension |

1400 x 1100 x 1200 mm |

|

software |

Artcam, Alphacam |

|

Dust system |

dust hood for spindle |

|

Tool Type |

Manual |

|

Command code |

G code |

|

Computer interface |

USB 2.0 |

Customer Feedback

Hot Searches