NaN / 0

HENTO Mobile Concrete Batching Plant / Mobile Concrete Mixer With Pump / Mobile Concrete Batching Plant

Get Latest Price

US$ 19999

≥1 Sets

US$ 18390

≥10 Sets

US$ 15390

≥50 Sets

Quick Details

Machine Type:

Mobile Concrete Batching Plant

Place of Origin:

Henan, China

Brand Name:

HENTO

Power:

35

Product Details

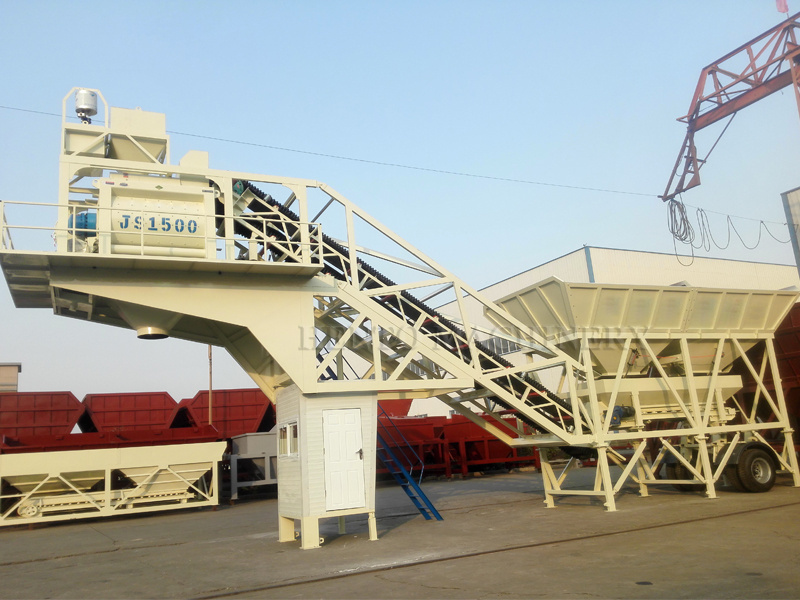

HENTO Mobile Concrete Batching Plant / Mobile Concrete Mixer With Pump / Mobile Concrete Batching Plant

Product Description

The mobile mixing plant is a mobile concrete mixing station equipment. Through ingenious design, the batching system, batching system, mixing system, storage, unloading, and automatic control system of the mixing station are centralized in a trailer unit, and the movement of the mixing station is realized through the trailer. HT-YHZS25 type mobile mixing plant can produce 25-square-concrete concrete output. It has the advantages of flexible movement, quick and easy assembly and disassembly, and stable performance. It is the preferred choice for field construction projects such as railways, highways, ports, bridges, and hydropower projects. model.

The mobile mixer is a highly integrated mobile concrete mixing plant. The main machine adopts a forced twin-shaft mixer, which has the characteristics of short stirring time, rapid discharge, even mixing, high productivity, and can produce plastic, dry hard and other concrete, reliable quality. Aggregate is measured by electronic weigher or measured separately. The cement, water, and additives are weighed and weighed. The measurement is accurate, and the microcomputer is centralized to control. The operation is simple, easy to adjust, and reliable. The aggregate uses bucket lifting or belt feeding. Siemens devices are used for electrical components, which have reliable performance and high production power. They are suitable for on-site mass production of concrete. The abradant liner and agitator blades are specially treated with wear resistant materials. The unique shaft end support and seal type greatly increase the service life of the main machine. The station is fully functional and has a complete composition of ingredients, mixing, metering, and control systems. It has a small footprint and high cost performance. It is suitable for the construction of small and medium-sized hydropower projects, highways, ports, airports, and bridges.

Technical Parameters

|

Model |

HT-YHZS25 |

|

Theoretical productivity |

25m³/h |

|

Mixer |

JS500 |

|

Stirring motor power |

30Kw |

|

Cycle |

72s |

|

Mixer nominal capacity |

750L |

|

Aggregate maximum particle |

80mm |

|

Batching station batching ability |

800L |

|

Aggregate bin capacity |

4*2.2m3 |

|

Aggregate belt conveyor productivity |

100m3/n |

|

Screw conveyor maximum productivity |

40t/h |

|

Discharge height |

3.8m |

|

Installed capacity |

105kw |

|

Aggregate weighing range and accuracy |

(0 ~ 3000Kg) ± 2% |

|

Cement weighing range and accuracy |

(0 ~ 1500Kg) ± 1% |

|

Water weighing range and accuracy |

(0 ~ 600Kg) ± 1% |

|

Admixture weighing range and accuracy |

(0 ~ 150Kg) ± 1% |

Product Pictures

Company Certificate

Packaging

Our customer

Contact Us

If you need further information, please contact us freely, we will do our best to cooperate with you.

Hot Searches