NaN / 0

GOOD Price Salt Spray Tester JIS Z 2371 Sandards Salt Spray Corrosion Test Chamber

Get Latest Price

US$ 1200

≥1 Sets

Quick Details

Power:

Electronic

Place of Origin:

Fujian, China

Warranty:

1 year

calibration certificate:

CE, ISO 9001

Product Details

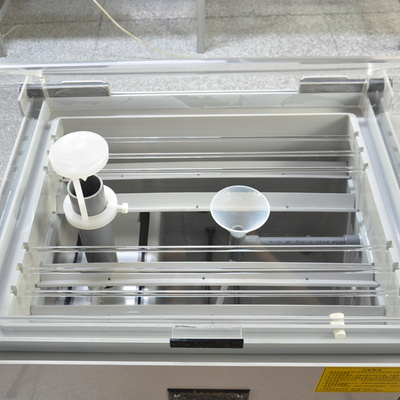

Nozzl

Product Description

GOOD Price Salt Spray Tester JIS Z 2371 Sandards Salt Spray Corrosion Test Chamber

Product introduction

Salt Spray Corrosion Test Chamber: It aims at determining the product corrosion resistance after various kinds of materials surface suffering electroplating, anodizing, painting, rust-proof oil corrosion resistance treatment.

It is suitable for neutral salt spray test (NSS) and acidic corrosion experiment (AASS, CASS).

0

Key Feature

- The whole equipment adopts material of 5mm import gray PVC sheet, Internal adopts advanced band produced three-dimensional reinforcement technology, with strong structure, no deformation, acid and alkali resistance, high temperature resistance, and no aging. It is applied to all kinds of test specifications such as salt spray, copper acetate, etc.

- Heating method: test room adopts steam direct heating method, temperature rise fast and uniform, reduce the standby time, the heating tube is made from titanium tube with high corrosion resistance.

- Hopper: 2 built-in spray quantity collection cylinder (only one 60 type ), comparing to the traditional external type, it does not easily break down.

- Laboratory commodity shelf uses plane dividing shelf, commodity shelf is the 10mm toughened glass rod with corrosion resistance. Plastic steel V type shelf and glass rod placing objects make sure the sample 30 degree bevel angle, the angle can be arbitrarily adjusted,the direction of spray falling around is the same as the direction of spay receiving, test piece is set with large quantity.

- Machine body support: SECC U-bar with angle iron spray paint, four wheel slide and can be pushed for moving( limit use for 120 L type or more than 120 L).

- Pressure barrel: 2.0MMSUS201 stainless steel seamless welding.

Dimensions

Specifications

|

Model |

GT-F50A-1 |

GT-F50A-2 |

GT-F50A-3 |

GT-F50A- 4 |

GT-F50A- 5 |

|

|

Inside chamber dimension |

60x45x40 |

90x60x50 |

120x100x50 |

160 x 100 x 50 |

200 x 120 x 60 |

|

|

Outside chamber dimension |

107x60x118 |

141x88x128 |

190x130x140 |

230 x 140 x 140 |

270 x 150 x 150 |

|

|

Test chamber volume |

108L |

270L |

600 L |

800L |

1440L |

|

|

Brine tank |

15L |

25L |

40L |

40L |

40L |

|

|

Power supply |

AC220V1Φ10A |

AC220V1Φ15A |

AC220V1Φ 30 A |

AC220V1Φ 30 A |

AC220V1Φ 30 A |

|

|

Temperature of test chamber |

Brine test method(NSS ACSS)35℃±1℃ |

|

|

Corrosion resistance test method (CASS)50℃±1℃ |

||

|

Temperature of pressure barrel |

Brine test method(NSS ACSS)47℃±1℃ |

|

|

Corrosion resistance test method (CASS)63℃±1℃ |

||

|

Brine concentration |

5% sodium chloride solution concentration or add copper chloride 0.26 grams per liter in the 5% sodium chloride solution concentration. (CuCl2 2H2O) |

|

|

Brine temperature |

35℃±1℃ 50℃±1℃ |

|

|

Power |

AC220V 50Hz |

|

|

Compressed Air Pressure |

1.00±0.01kgf/cm2 |

|

|

Spray volume |

1.0~2.0ml/80cm2/h (gather at least 16 hours, take its average) |

|

|

Relative temperature of test chamber |

Above 85% |

|

|

PH-value |

6.5~7.2 3.0~3.2 |

|

|

Spray method |

continuous spray or intermittent spray |

|

|

Temperature range |

Lab temperature |

35℃ -50℃( can be arbitrarily set) |

|

Pressure barrel temperature |

47℃ - 63℃( can be arbitrarily set) |

|

|

Speed of temp rising |

Laboratory |

Room temperature →35℃ about 35 minutes |

|

Pressure barrel |

Room temperature →47℃ about 15 minutes |

|

|

Temp accuracy |

±1℃ |

|

|

Standards |

CNS3627, 3885, 4159, 7669, 8886, JIS D-0201, H-8502, H-8610,K-5400, Z-2371, ISO 3768, 3769 , 3770 , ASTM B-117, B-268,GB-T2423, GJB 150 |

|

Control system

1.Import DHC temperature controller uses digital display, Digital PID control algorithm and SSR output, high stabile platinum temperature measuring probe, ±0.1℃ error.

2.The temperature is ±1℃ during the spray test.

3.Saturation pressure barrel adopts Henry's law, laboratory humidity above 95% accords with national standard. It is used to heating and humidification, and supply the required temperature of the test room,its material is SUS# 304 stainless steel with the best heat preservation effect, visual connectors and drainage switch are attached so as to observe the water level of saturation pressure barrel and easily clean.

Product Image

0

Packaging & Shipping

FAQ

FAQ

- Q Is your company a trading company or factory?

- A Factory + trade (integration), has 20 years focusing on test instruments field, 6 years exporting experience.

- Q After an order is placed, when to deliver?

- A Generally about 10-25days, If we have inventory, we can arrange shipment within 3 days. Please be aware that our production lead times depend on specific items and item quantities.

- Q What’s the payment term?

- A T/T,L/C and other payment terms could be negotiated.

- Q What's the warranty and after-sales service?

- A 12 months warranty. Feedback to you within 24h and help you to repair your problem controller freely, even it's not from our factory.

- Q What the standards do you adopt?

- A We have been adopting the world standards and regulation such as ISO, ASTM, DIN, EN, GB, BS, JIS, ANSI, UL, TAPPI, AATCC, IEC, VDE, and CSA .

- Q What about the product' services and quality?

- A Each instruments must be carried out 100% quality examination and test when shipping and delivery goods. Product use training, each of our product provide video training to show you how to install & operate. We can arrange engineer to train the operation of equipment to customer’s company when you need. And our Main clients : SGS, BV and Intertek.

Hot Searches