Rotary seals and Shaft Seals are used in components with oscillating or rotating parts to keep lubrication fluids in while preventing ingress of mud and water. Trelleborg seals help improve components life and long term performance.

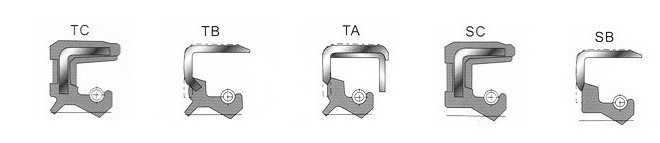

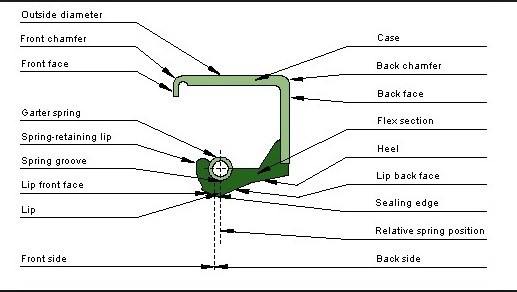

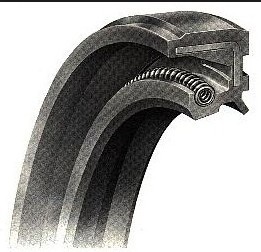

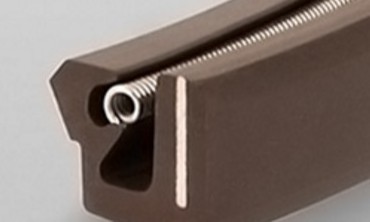

Rubber Oil seal consists of three parts: the seal body, strengthen the skeleton and the self-tightening spiral springs.The role of oil seal of the transmission components in general is in need lubrication components and parts output isolation, and typically used for rotating shaft is a rotary shaft lip seal. It can be divided in the seal, the outer seal, the inner and outer exposed skeleton oil seal.

|

Product Name

|

Standard mechanical radial aoto part rotary shaft sealing rubber oil seal

|

|

Brade

|

DL SEALS

|

|

Color

|

black, brown,red

|

|

Material

|

NBR, FKM

|

|

Working Temperature

|

- 35+220°C

|

|

Working Pressure

|

0~0.05MPa

|

|

Working Medium

|

lubricating oil, grease, water, etc.

|

|

Used

|

Cranes, tractors, forklifts

|

Rotary seals and Shaft Seals are used in components with oscillating or rotating parts to keep lubrication fluids in while preventing ingress of mud and water. Trelleborg seals help improve components life and long term performance.

In a static sealing application there is no movement between sealing surfaces or between the seal surface and its mating surface.

Oil seals are available in numerous lip materials. Popular materials include felt, leather, urethane, nitrile, polyacrylate, ethylene-acrylic or polyacrylic, silicone, fluoro-elastomer, tetrafluoro-ethylene propylene and PTFE. Use of one material over another is application specific, as materials will have different temperature and speed ranges.

Lip type shaft oil seals are widely used in rotary screw airends and come in a variety of designs and materials. This seal functions to retain the oil inside the airend, but also to keep air, dust and dirt from sucking in along the rotating shaft when the machine is off load. (When the inlet valve closes, if the airend continues to rotate, a vacuum may be pulled on the inlet end.)

*Service Temperature

For NBR the service temperature can be designed from -55 C to 100 C or up to 130 C depending on differenacrylonitrile content and formula.

*Application

NBR compounds have excellent resistance to abrasion, non-polar oils and solvent, water and permeation (higher acrylonitrile content will be better). NBR also can be used in conditions of dilute acids, alkalis and salt solution at low temperatures.

*Service Temperature

For general type Viton the service temperature is better limited to approximately from -26 C to 232 C in static applications, though the service temperature can arrive to 275 C at short time In dynamic applications, it is suitable between -15 C and 200 C.

*Application

Because FKM has excellent resistance of high temperature, oil, solvent, flame, chemicals and weathering, it is usually applied in automotive, chemical processing, aerospace and many other industries.

*Service Temperature

For Silicones the service temperatures are from -60 C to 225 C. Some special types can be used in extreme temperature up to 300 C and down to -100 C.

*Application

Silicone rubber performs well under environmental and temperature extremes. It is usually applied in automotive and aerospace industries where flexibility and longevity are important. It is also a suitable material for parts that need FDA approval for food handling equipment and appliances.

*Service Temperature

PTFE's mechanical properties are low compared to other plastics, but its properties remain at a useful level over a wide temperature range of -100°F to +400°F (-73°C to 204°C).

*Application

PTFE is the common sealing material used for making wear ring, backing-up ring, o ring, gasket, etc. It can be found in metallurgy machinery, petrochemical machinery, engineering machinery, and light industrial machinery.

A: Of course we can make from your structure drawing.

A: Sure, we may consider discounts for bulk order of products.

A: Our products have sold to America, India, Korea, Africa, Iran and other countries over the world.

A: Yes,we can provide you FKM, PTFE, etc.according to your requirements.