NaN / 0

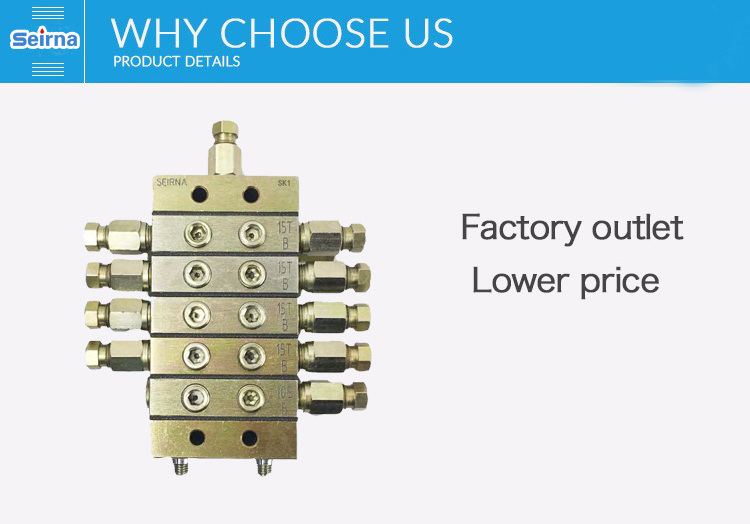

High Quality Distributor Butter Distribution Valve SK1000 Progressive Distributor Chip Distributor For Forging Machine Tools

Get Latest Price

US$ 65

≥1 Pieces

Quick Details

Application:

Light Industrial Machinery, Casting Machinery, Rubber Machinery, Forging Press Machine, Crane

Pressure:

High Pressure

Voltage:

Standard

Warranty:

1 year

Product Details

SK1 Progressive Distributor

SK1 distributor is a small chip type progressive distributo.A series of plungers in the distributor reciprocate.The distributor is generally the main distributor in the system,In the case of few lubrication points can be used as the main distributor.Widely used

in cranes, casting machinery, forging machine tools,engineering machinery, construction machinery, rubber machinery, light industry, environmental protection and other machinery.

Dimensions

Parameters

| serial number |

Valve specification |

Standard Displacement ml/cyc |

Withstand voltage Mpa |

Starting pressure Mpa |

Number of oil outlet |

| 1 | 05T | 0.08 | 15 | 1.4 | 2 |

| 2 | 05S | 0.16 | 1 | ||

| 3 | 10T | 0.16 | 2 | ||

| 4 | 10S | 0.32 | 1 | ||

| 5 | 15T | 0.24 | 2 | ||

| 6 | 15S | 0.48 | 1 |

Characteristics

- Each working valve plate has 1-2 oil outlets

- There are many specifications for the working valve plate, and the displacement specification can be selected according to the demand of the lubrication point

- Plunger precision machining, oil outlet pressure up to 15Mpa

- Each group of dispensers can be equipped with a mechanical indicator to facilitate the monitoring of lubrication points. It can also be used with a micro switch for blocking monitoring or metering times

- The distributor includes a first piece, a tail piece and 3-18 working valve pieces

- The pressure alarm can be added to each oil outlet as required. When the lubricating point is blocked, the pressure alarm of the lubricating point will give alarm indication

- The maximum working frequency of plunger is 200cyc/min, and the indicator installed shall not exceed 60yc/min

Hot Searches