NaN / 0

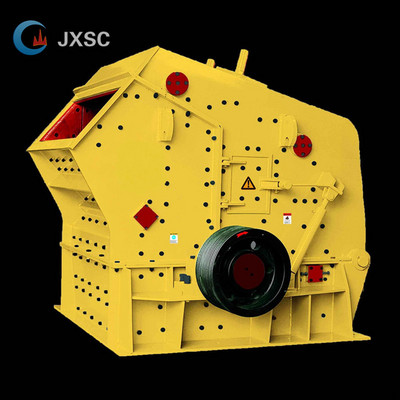

Hot-Selling Pf-1214 Small Diesel Engine Impact Crusher Price Barite Rare Earth Clay Kaolin Hazemag Mobile Impact Crusher

Get Latest Price

US$ 20800

≥1 Sets

US$ 5500

≥5 Sets

Quick Details

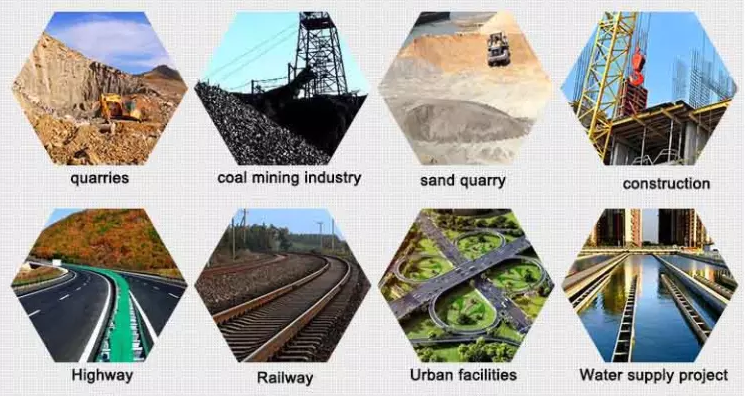

Application:

Quarry, mining, coal mining

Capacity(t/h):

130-180

Place of Origin:

Jiangxi, China

Brand Name:

JXSC or OEM

Product Details

Product Description

Hot-Selling Pf-1214 Small Diesel Engine Impact Crusher Price Barite Rare Earth Clay Kaolin Hazemag Mobile Impact Crusher

Product introduction:

The impact crusher is mainly used in metallurgy, chemical industry, building materials, hydropower and other materials that often need to be relocated, especially for the operation of fluid stone materials such as highways, railways, hydropower projects, etc. Different configurations of finished materials require multiple configurations. China's current mobile crushing stations are mostly used in construction waste disposal projects in urban demolition. Crushing and sieving construction waste into several kinds of recycled aggregates of different sizes and rules is the basis of the project to realize the reuse of construction waste in China.

Application Field:

The impact crusher (impact crusher) is mainly used in industrial sectors such as metallurgy, mining, cement, chemical industry, refractory materials and ceramics, as well as highway construction, water conservancy engineering, construction crushed stone, and machined sand processing.

Suitable Material:

Due to the characteristics of its wearing parts, the impact crusher is limited in the application of materials with higher hardness. It is more suitable for coarse, medium and fine crushing of various soft and medium hard ores, such as Feldspar, calcite, talc, barite, rare earth, clay, kaolin, dolomite, kaolin, gypsum, graphite, etc.

Principle of Operation:

The impact crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at a high speed. When the material enters the area of the hammer, it strikes and breaks with the hammer on the rotor, and then is thrown to the counterattack device to be broken again, and then rebounded from the counterattack liner. Return to the impact area of the hammer to re-crush. This process is repeated. The materials enter the first, second and third counterattack chambers from large to small to be crushed repeatedly until the material is crushed to the required particle size and discharged from the discharge port.

Performance characteristics:

1) A novel structure, unique, stable operation, multi cavity uniform broken,suitable for crushing hard rock.

2) Low energy consumption, high yield, high crushing ratio, for general 10-20, high upto 50-60.

3) With the shaping function, product is cubic shape, high packing density, adjustable discharge size, simplified crushing process.

4) All the whole plate structure to discharge is small size and cubic, no inner crack.

5) Feeding port is low and big, easy to arrange production line and increase the feed size.

6) Impact crusher use of new wear-resistant material, so the plate hammer, impact plateand lining board has longer service life.

7) Easy to use and repair, can be used as selective crushing.

8) Unique tooth type impact lining board, especially suitable for crushing hard rock, high efficiency and energy saving.

|

Model

|

Rotor Spec (mm)

|

Feed opening size (mm)

|

Max Feed edge(mm)

|

Capacity (t/h)

|

Motor Power(kw)

|

Weight(t)

|

Overall Dimension

(L*W*H)mm

|

|

PF-1007

|

1000*700

|

400*730

|

300

|

30-50

|

37-55

|

9.5

|

2400×1558×2660

|

|

PF-1010

|

1000*1050

|

400*1080

|

350

|

50-80

|

55-75

|

12.2

|

2400×2250×2620

|

|

PF-1210

|

1250*1050

|

400*1080

|

350

|

70-120

|

110-132

|

14.9

|

2690×2338×2890

|

|

PF-1214

|

1250*1400

|

400*1430

|

350

|

110-180

|

132-160

|

18.6

|

2690×2688×2890

|

|

PF-1315

|

1320*1500

|

860*1520

|

500

|

160-250

|

180-260

|

19.3

|

3096×3273×2667

|

|

PF-1320

|

1320*2000

|

860*2030

|

500

|

160-350

|

300-375

|

28

|

3096×3560×3185

|

|

PF-1520

|

1500*2000

|

1315*2040

|

700

|

300-500

|

400-450

|

42.8

|

3890×3560×3220

|

Related Products

Our Company

Jiangxi shicheng Mine Machinery Factory

was established in 1985, it's a professional machinery factory special in mining equipment research, manufacturing, sales and offers professional mine processing plant workflow design, plant installation, equipment maintenance, beneficiation processing technology guidance service as one of the metallurgical machinery equipment factory. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Congo, Uganda, Mozambique, Angola, Southeast Asia, South America and many other coutries and regions.We are committed to creating high quality and efficient crushing and screening equipment,quality is our eternal pursuit and responsibility.

Our Workshop

Our Customers

Our successful Case

South America impact crusher production line site

Malaysian impact crusher production line

Oman customer's production line

Packing & Shipping

Certifications

Our Service

●

Pre-sales service:

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

●

Sales service:

Send technicians to the jobsite guiding the installation and adjustment, training operators and finishing the check and accept together with you.

●

After-sales service:

To establish long term friendship, we will reg-ularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

●

Lifelong service:

One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

●How long is the guarantee?

All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

●

What is the delivery time?

According to the specific data provided by the customer,our customized crushing machine`s delivery time is 30-48 days.

●

What is the nearest port?

Xiamen, Guangzhou, Shenzhen

●

What is the trade terms?

CIF,FOB,DDU ect is acceptable.

●

Service and Payment Terms?

We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

|

JIANGXI SHICHENG MINE MACHINERY FACTORY

|

|

|

|

Contact Person:

|

Lori Luo

|

|

|

Mobile/ Wechat/ Whatsapp/ Skype:

|

+86 178 7052 9962

|

|

|

Website:

|

www.jxscmine.com

|

|

Hot Searches