NaN / 0

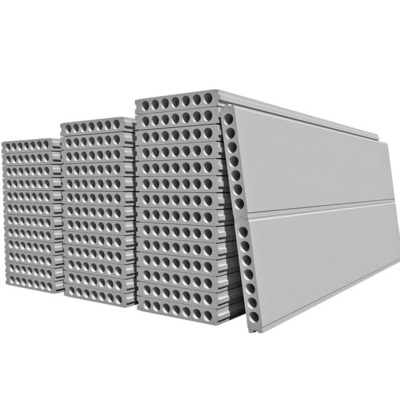

Precast Concrete Eps Wall Panel Making Machine In Saudi Arabia lightweight sandwich Cement Wallboard Molding Machine T beam

Get Latest Price

US$ 28866

≥1 Pieces

US$ 21808

≥5 Pieces

Quick Details

Marketing Type:

Hot Product 2023

Application:

Hotel, apartment, office building,shopping mall

Production Capacity:

800m2/day

Place of Origin:

Guangxi, China

Product Details

Precast Concrete Eps Wall Panel Making Machine In Saudi Arabia lightweight sandwich Cement Wallboard Molding Machine T beam

|

|

Our machine support making different shapes of wall panels, like" T " shape and "L" shape, which are usually be placed on the corner of the building.

1,Application of the Machine: to form the wall panel,curing and demolding

2,Raw materials to produce the wall panel: Cement/sand/fly ash/EPS beads/HPMC and other chemical addtitives/water

3,Side/surface cover of the wall panel: Calcium silicate board/Cement fiber board, also can be without side cover

4,Usage of the wall panel: Partition wall construction of school,hospital,commercial building,office and residential house

Raw Materials

- Good thermal isolation EPS bonding mortar as core material.

- Calcium silicate board / Fiber cement board as the surface material.

- Properly mixed with fly ash, slag and additives .

Eps Cement Insulated Sandwich Panel For Wall Panel Making Machine t beam wall panel machine corner wallboard production line

Production System:

(1) Moulding Machine

(2) EPS Expanded Machinery

(3) Mixing Machinery

(4) Mobile Slurry Grouting Machine

(5) Mobile De-Moulding Turnover Platform

HONGFA EPS Cement Panels Advantages

(A) Lightweight:

The raw materials used are Lightweight aggregates, fly ash,etc, non-reinforced concrete, gravel and other heavy feedstock. So it has the characteristics of lightweight, which is only 1/16 weight of the brick and concrete structure.It can significantly reduce the vertical load of the building structure and reduces building weight and project cost.

(B)Insulation Resistance:

As this new wall panel is core of EPS insulation materials, which insulation performance is extremely advantageous and meet the building energy efficiency design standards, and rank first among similar products.

(C) Permeability Resistance:

The bibulous rate of this new wall panel is only 3.3%,which has reached the international advanced level in the same industry.

(D) Fireproof performance:

this kind of wall panel is non-burning, and according to the testing, it is reasonable fireproof materials, for the 90mm thickness wall panel, the fireproof performance can be more 3 hours.

(E) Soundproofing:

As new wall panel is using EPS as core, it has good sound insulation and air aspiration, which is more than 40 db sound insulation.

Low business risk for establishing the EPS sandwich wall board machinery.

(A) long-term stability advantages: Due to the limit of functional requirements of the restrictions and sources of raw materials needed to be broad and rich , but also by limiting the requirements of the human environment, the wall construction material development developers is relatively difficult.Once this kind of wall material is successfully developed and is recognized by the government and society,its competitive advantage will be relatively stable and long-term business in the market.

(B) Mechanization in production, so less workers but high output and stability.

(C) It is a comprehensive utilization of the industrial wastes project, and will get a great support from the Government.

Production Line

welcome to visit our factory site !

Successful Plant

1:Automatic Vertical Lightweight Concrete Wall Panel Making Machine HPF530A

Automatic operation, high output,fewer workers required.The most advanced patent protected machine in China. Double capacity Higher working-efficiency. It is automatic operation with double side opening, High capacity and with fewer workers. The EPS lightweight wall panel machine is most labor-saving and fastest now in China.

2:Horizontal type Lightweight Precast Concrete Wall Panel Making Machine HFP512A

This EPS wall panel making machine is automatic type, easy operation and less workers.

3:Semi automatic vertical Lightweight Concrete Wall Panel Making Machine HFP540M

Manually install the moulds and boards, the highest output amount the three types, but requires more workers. This kind of sandwich lightweight wall panel machine is in lowest investment.

FAQ

1.Can this machine make my panel or other size panel?

We would design and do the mould according to customer's drawing or as ours.

2.Are your company is the manufacture or trading company?

We are direct factory,not agent or trading company,and the quality and after-sale services is guaranteed.

3.How can I trust the machines quality?

Our products passed ISO9001-2000 and CE identifications, and we making machines for 30 years,with full experience,updating technical idea and application.Furthermore our machines have been exported to more than 96 countries and always have a good reputation from our oversea customers.We will do fully test our products before shipment,make sure every equipment work well when they come to your hand.

4.When do you delivery the goods?

Normally 30 days after receipt of deposit and moulds confirmation from the buyer.

5.What about the payment?

30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

Hot Searches